Optimum regeneration of diesel particulate filters and NOx traps using fuel reformers

a technology of fuel reformer and diesel particulate filter, which is applied in the direction of machines/engines, mechanical equipment, human health protection, etc., can solve the problems of low efficiency of diesel engine, high emissions of nosub>x/sub>and particulates, and the inability to generate a self-supporting burn in the filter, etc., to achieve the effect of reducing the environment and reducing the amount of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

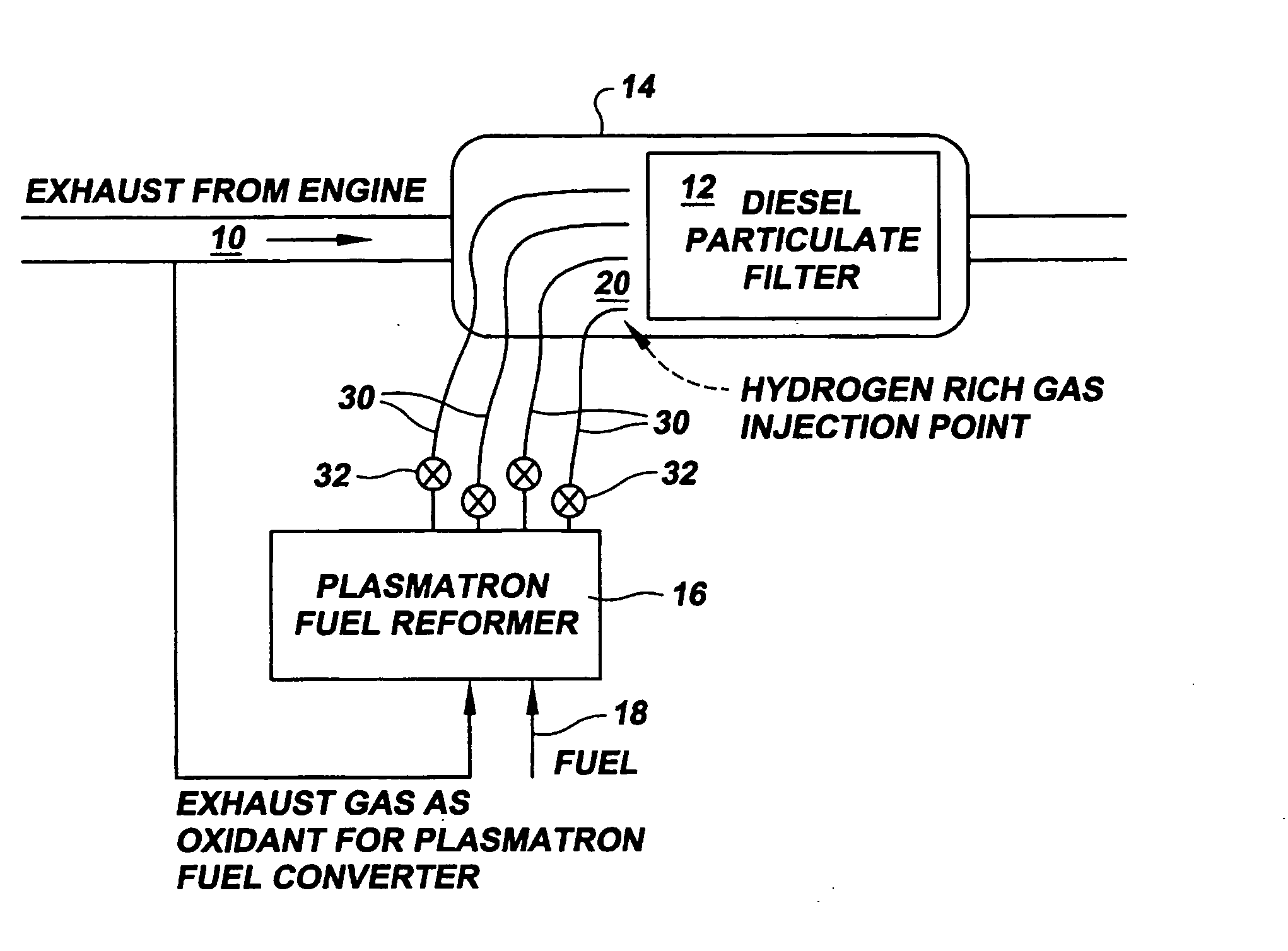

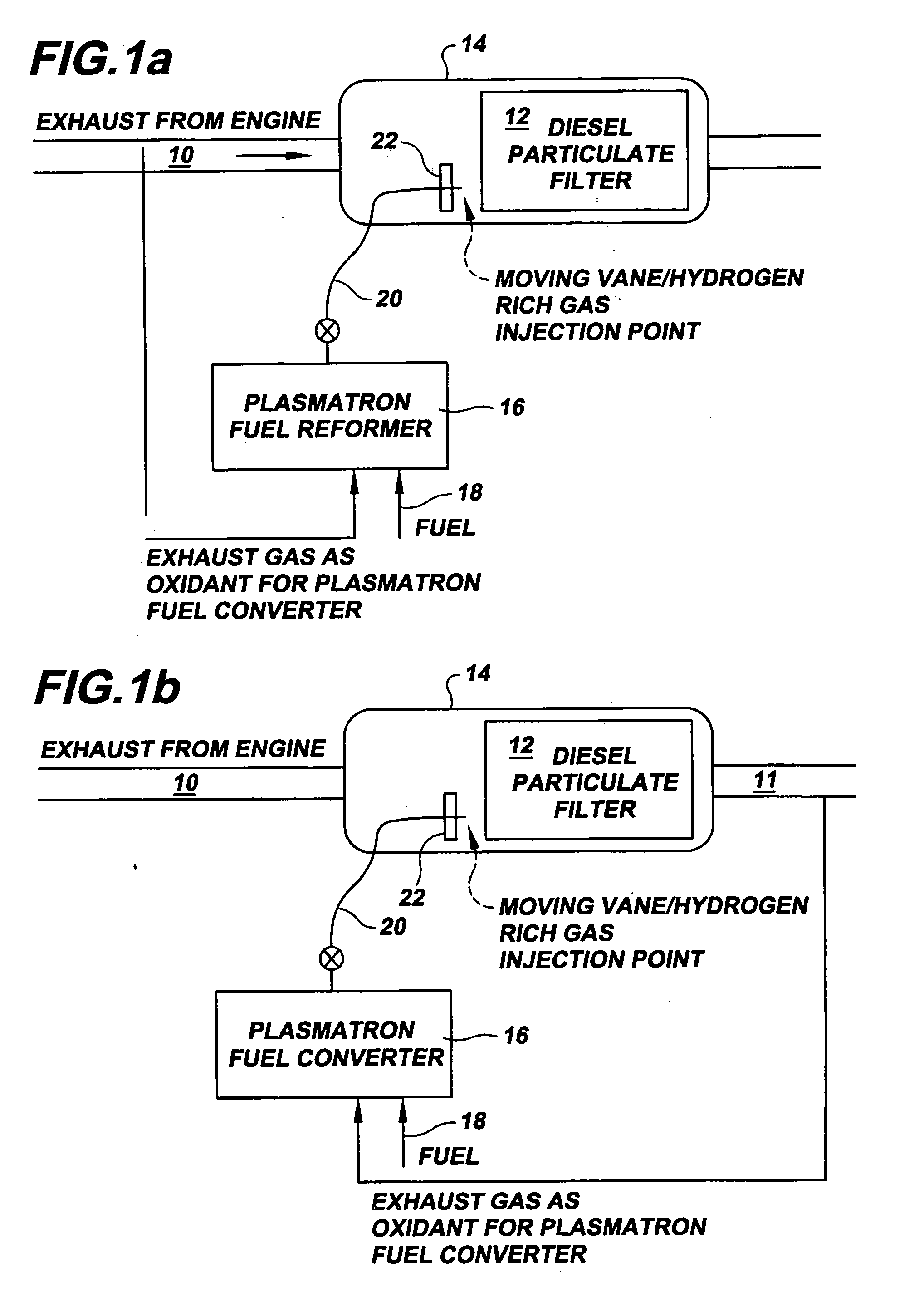

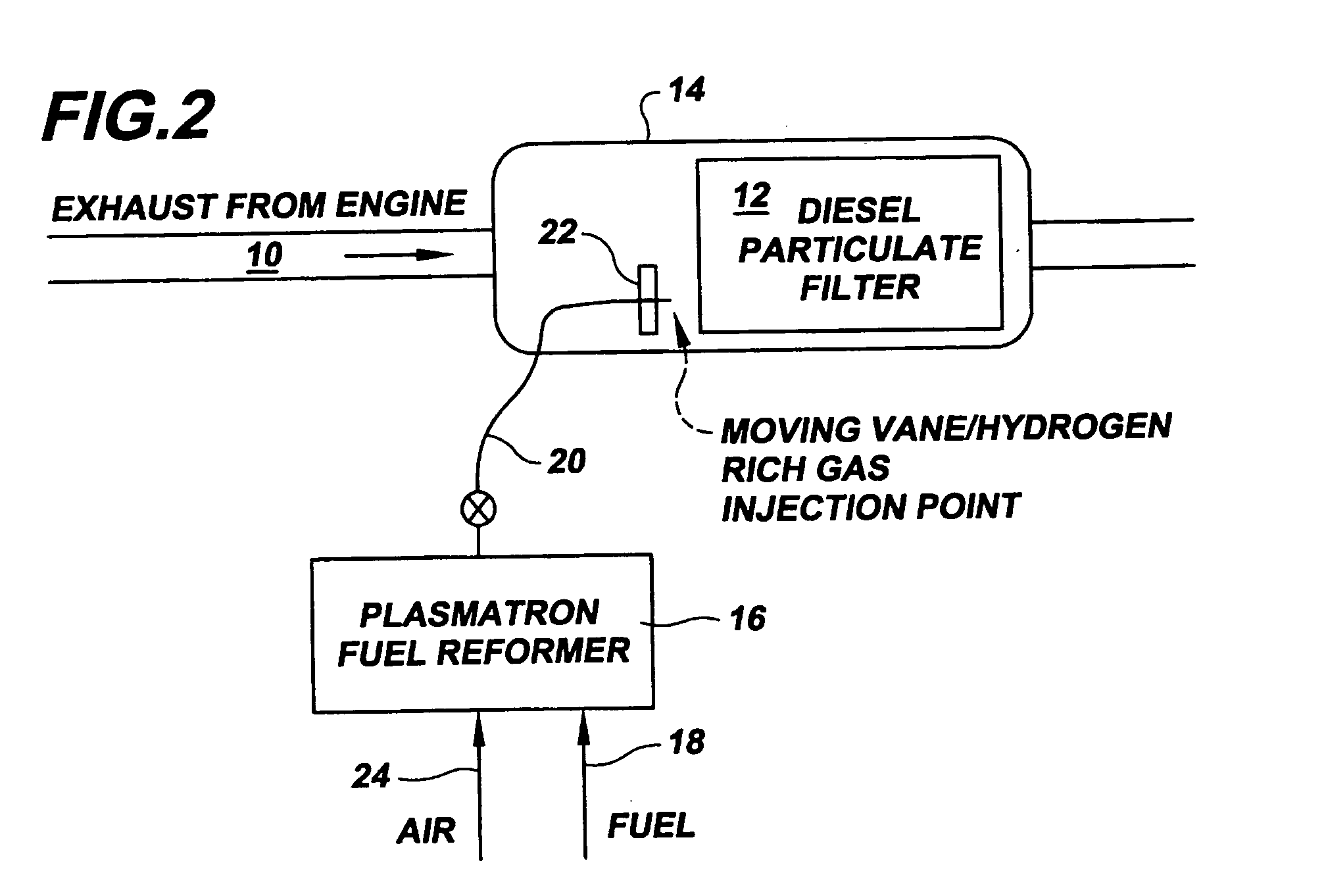

[0026] Hydrogen rich gas is an attractive fuel for regenerating a diesel particulate filter because hydrogen rich gas has a wide flammability range and low ignition energy thereby facilitating reliable combustion in the dilute environment of an exhaust gas stream. A fuel reformer such as a plasmatron fuel reformer converts onboard fuel such as diesel fuel into hydrogen rich gas. The output of such a fuel reformer includes hydrogen, carbon monoxide, nitrogen and other light hydrocarbons in addition to water and carbon dioxide at high temperatures. Importantly, the size of the fuel reformer can be minimized by using a system that regenerates only a fraction of the diesel particulate filter at any one time.

[0027] The regeneration of the diesel particulate filter can be controlled by changing the O / C ratio of the fuel reformer and the flow rate. It may be advantageous to start regeneration with high hydrogen rich gas temperatures and flow rates, and later reduce the O / C ratio and contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com