Aluminum alloy for casting-forging, aluminum casting-forging product and processes for production thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0055] Examples of the present invention will hereinafter be described, but the present invention is not limited to these examples.

examples 1 and 2

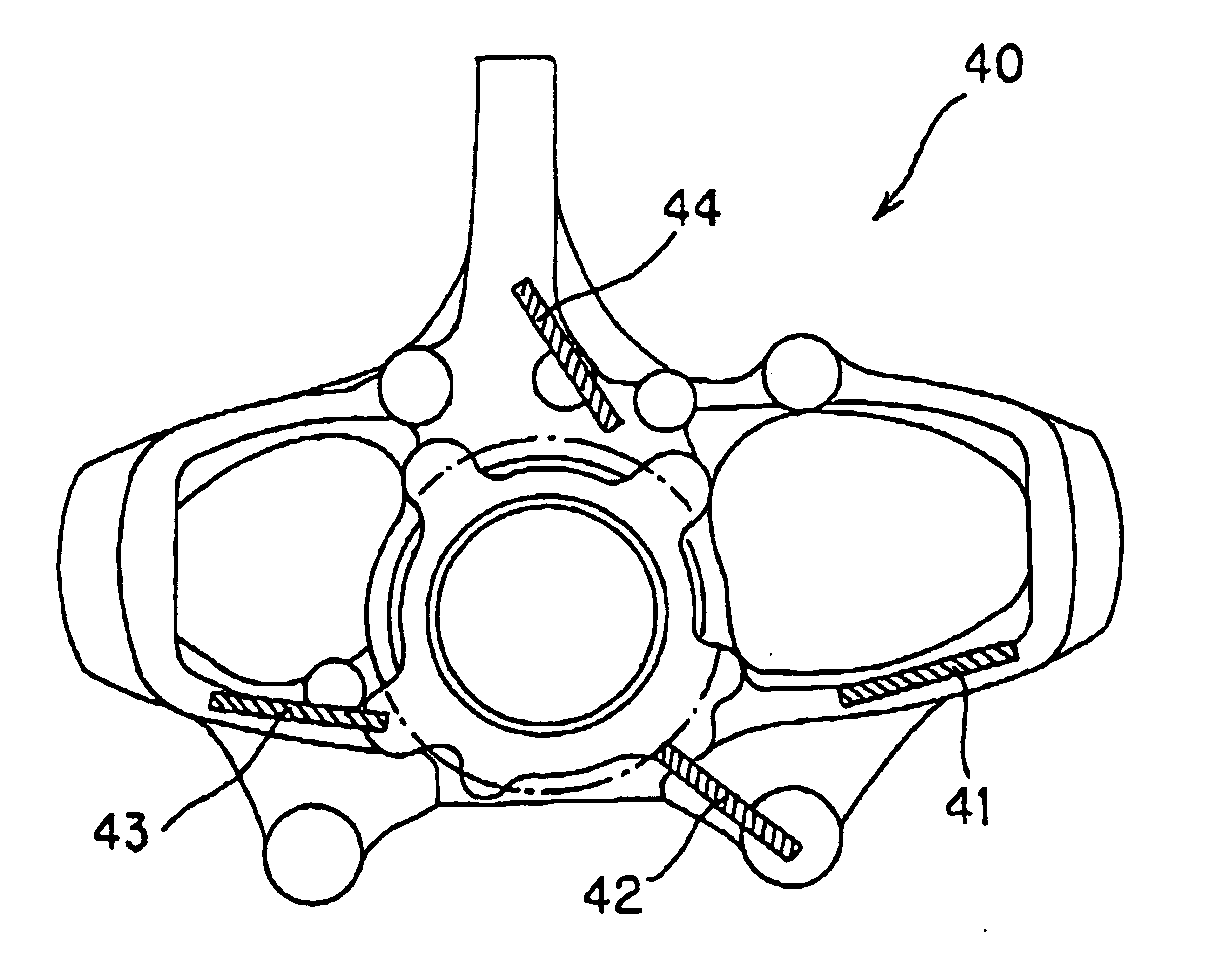

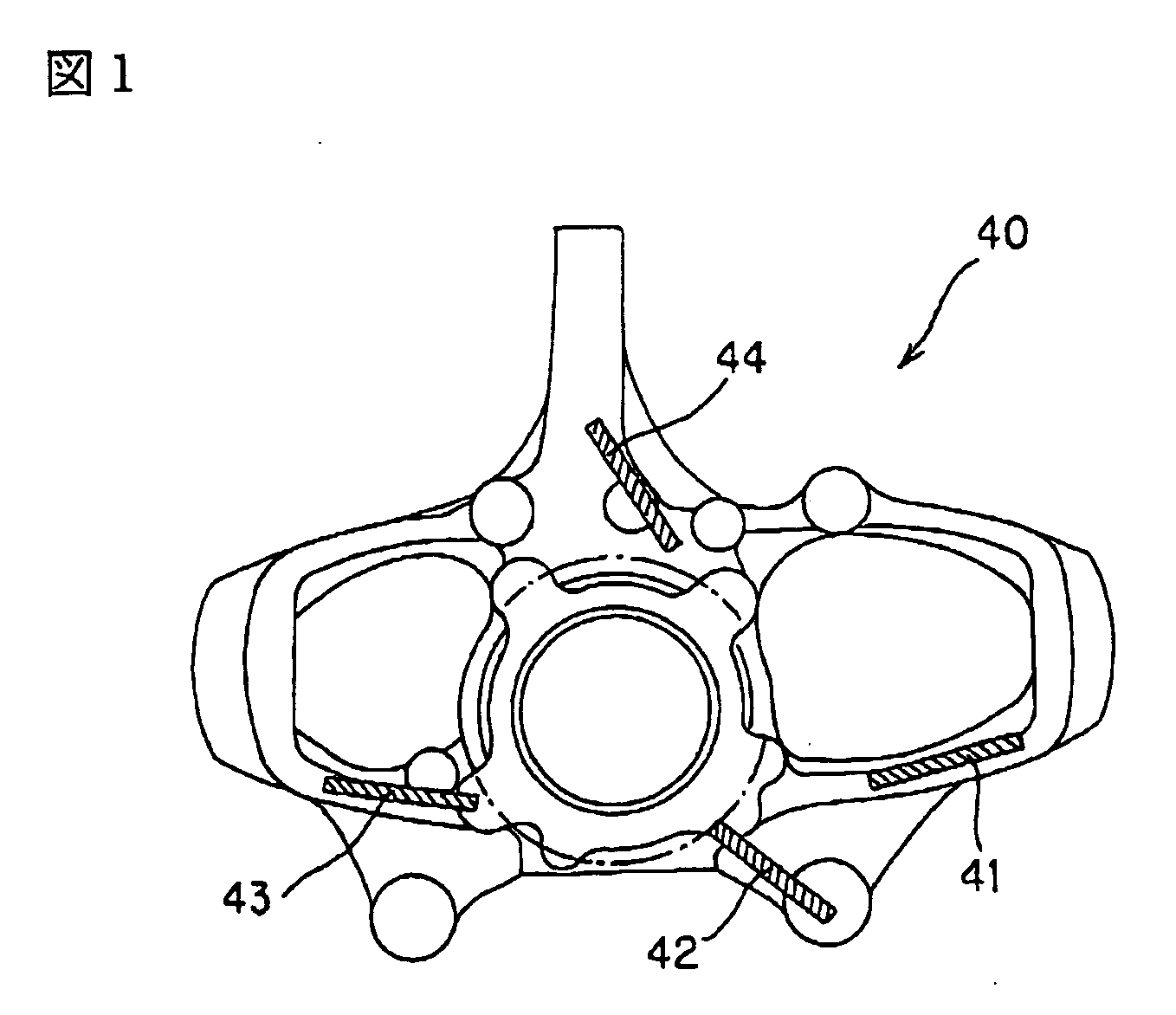

[0056]FIG. 1 is a diagram showing one example of the aluminum cast-forged product of the present invention. A steering knuckle 40 which is the part for the automobile is shown. A small amount of copper was added to scraps of A6082 alloy to prepare a raw material forming the aluminum alloy consisting essentially of 0.6 to 1.8 wt % of silicon, 0.6 to 1.8 wt % of magnesium, 0.8 wt % or less of copper, 0.2 to 1.0 wt % of manganese, 0.25 wt % or less of chromium, 0.0 to 0.15 wt % of titanium, and unavoidably contained impurities. Using this raw material, the steering knuckle 40 having a shape shown in FIG. 1 was manufactured in accordance with the following steps.

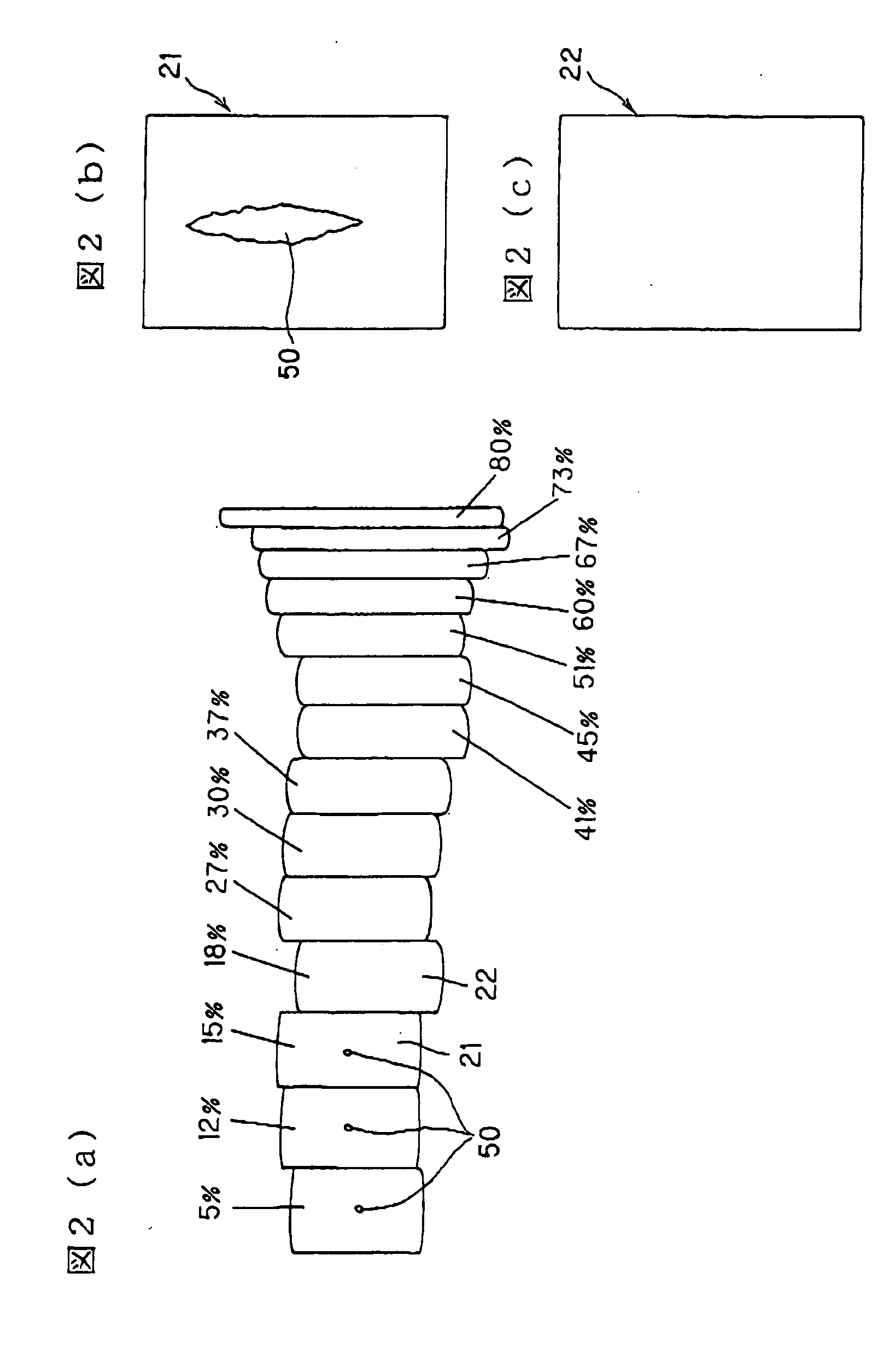

[0057] After the raw material was melted at a molten metal temperature of 728° C. to obtain the molten metal, the raw material for forging having a shape with a forging ratio of 30% assuming that the shape of the final steering knuckle 40 was 100% was cast at a mold temperature of 100° C. Next, die forging was performed using a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap