Method and apparatus for cooling engines in buildings at oil well sites and the like

a technology for cooling engines and oil wells, applied in the direction of liquid cooling, engine components, cooling system control, etc., can solve the problems of large loss of energy, overheating problems, and relatively inefficient internal combustion engines, and achieve economical and convenient connection, reduce problems, and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

:

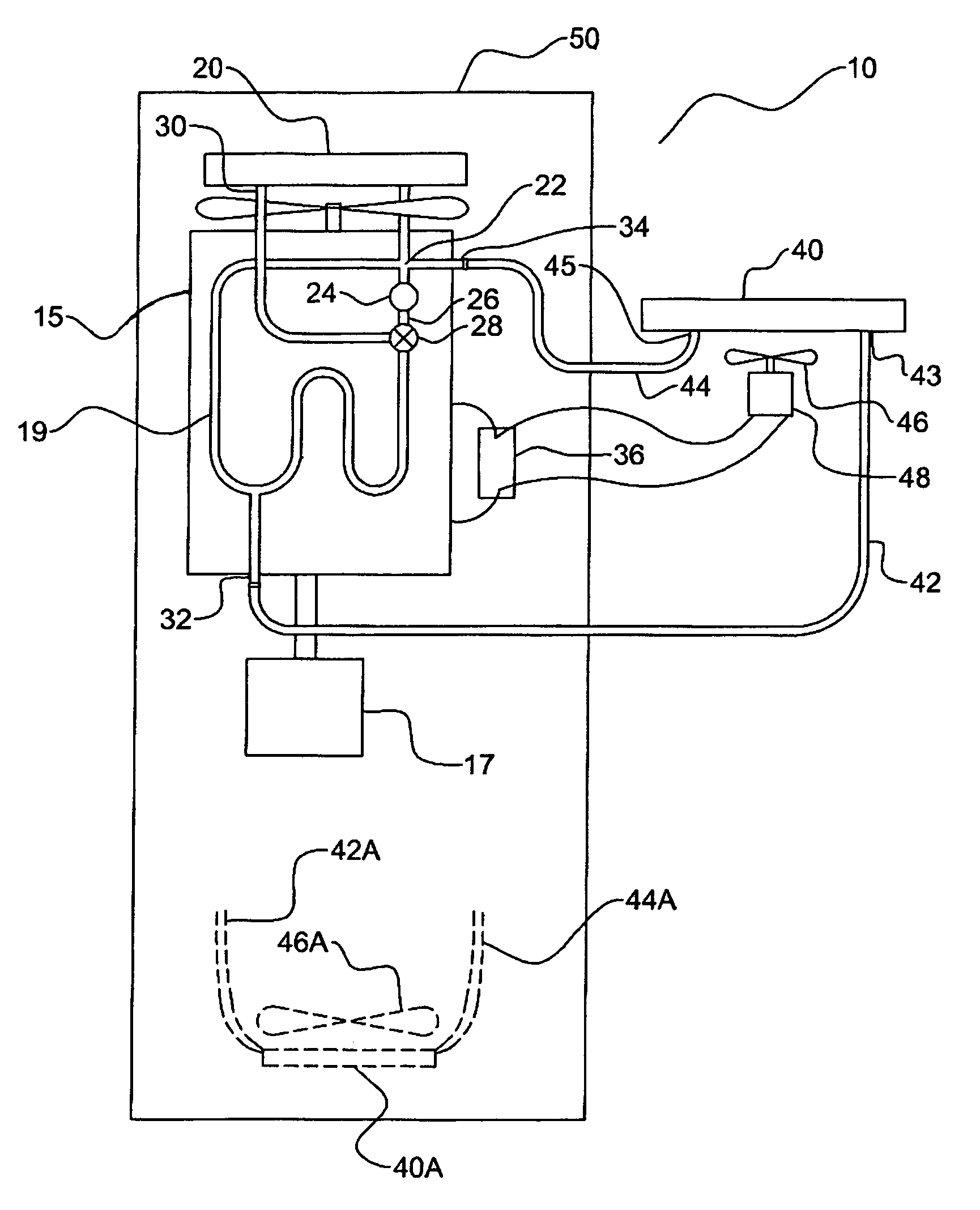

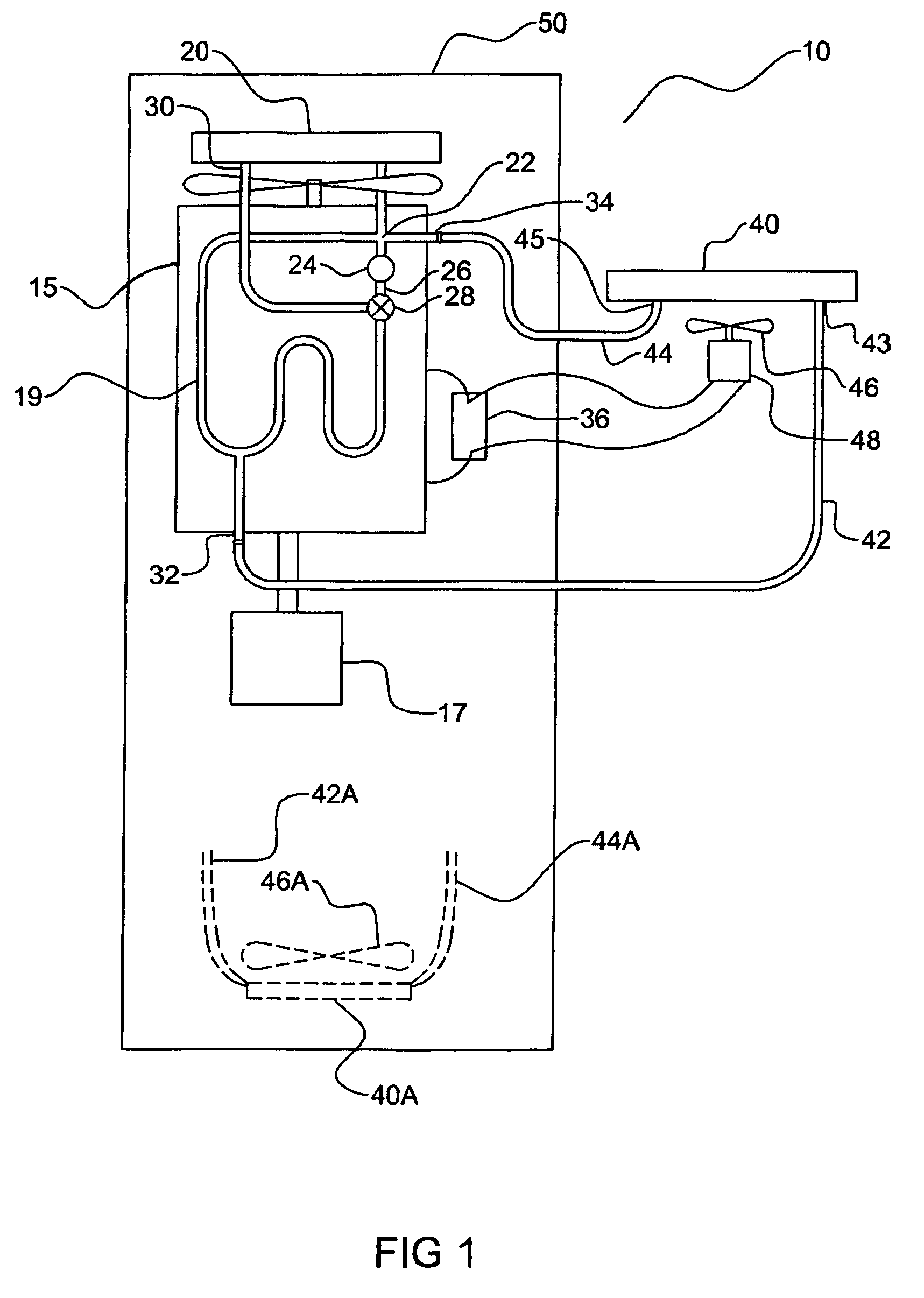

[0019]FIG. 1 schematically illustrates a stationary internal combustion engine system, incorporating an auxiliary cooling system 10 of the present invention. The stationary internal combustion engine system comprises a stationary internal combustion engine 15 located within a protective building 50 which serves to protect equipment including the engine 15 and typically other equipment. The illustrated engine 15 is connected to an auxiliary cooling system 10 to provide added cooling of the engine and reduce over-heating.

[0020] The engine 15 is a stationary internal combustion engine and is used to power a device, for example a hydraulic pump 17 that drives a rotary pump in an oil well, that is connected to the drive shaft of the engine 15. The engine 15 has a cooling system comprising a heat exchanger in the form of a main radiator 20 connected to the intake 22 of a pump 24. The pump output 26 is connected to a thermostat valve 28 which initially at start up is closed and directs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com