Non-detonable explosive scent training tool

a scent training and non-detonation technology, applied in the field of explosive scent training tools, can solve the problems that items classified as 1.4s explosives may be shipped in an essentially unregulated manner, and achieve the effects of reducing shipping and storage costs, reducing the risk of contaminating the scent source during handling and cleaning, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

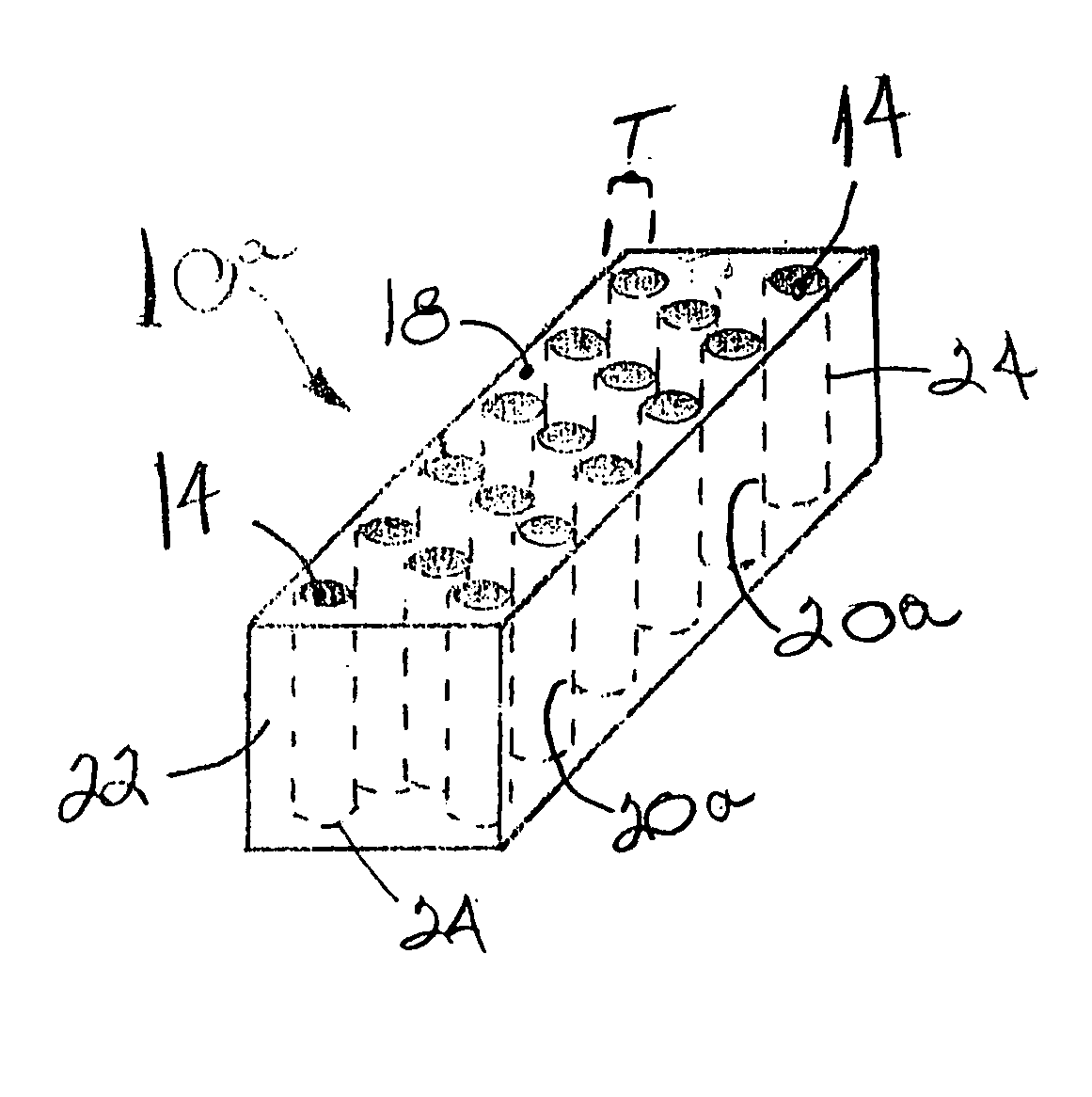

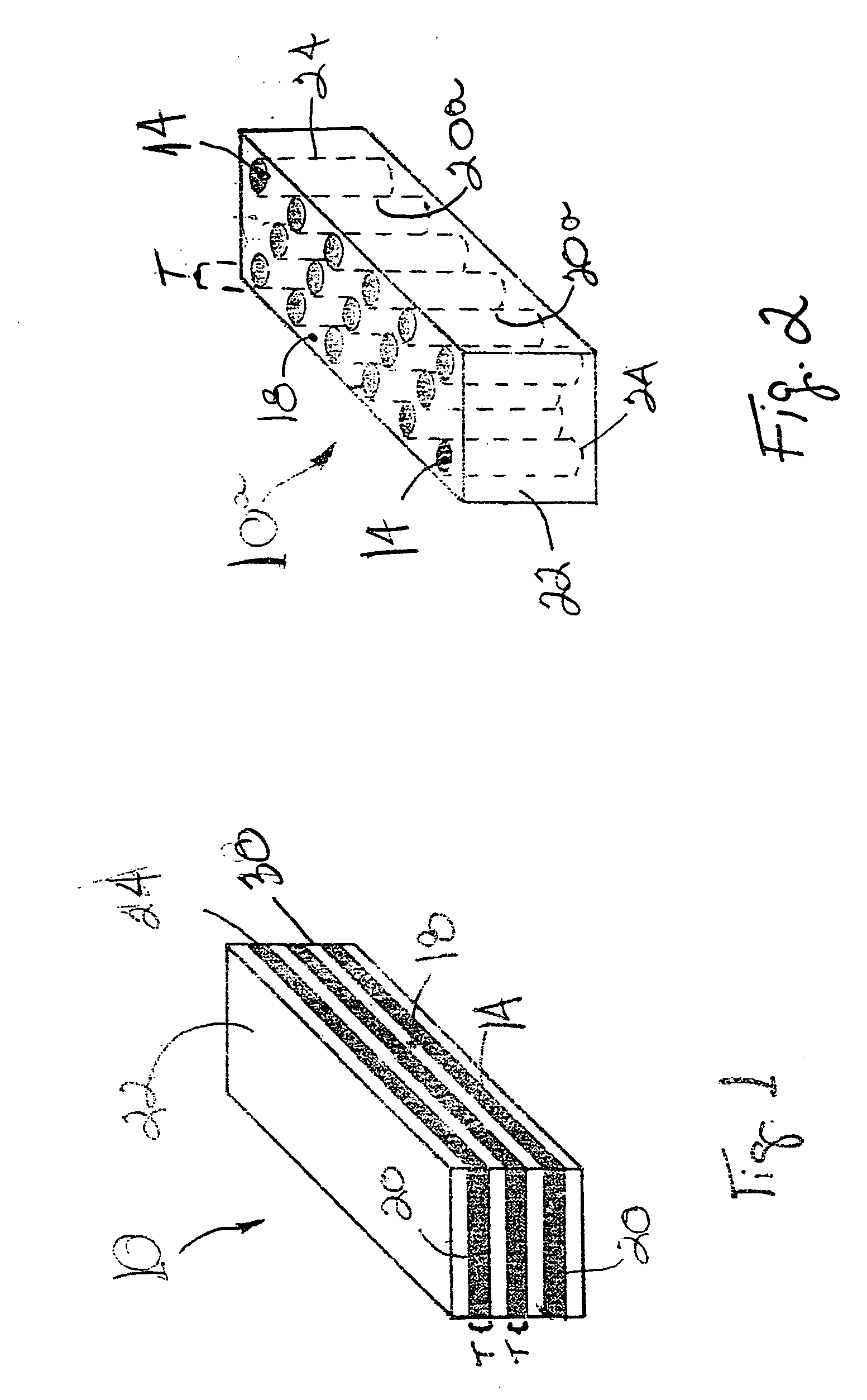

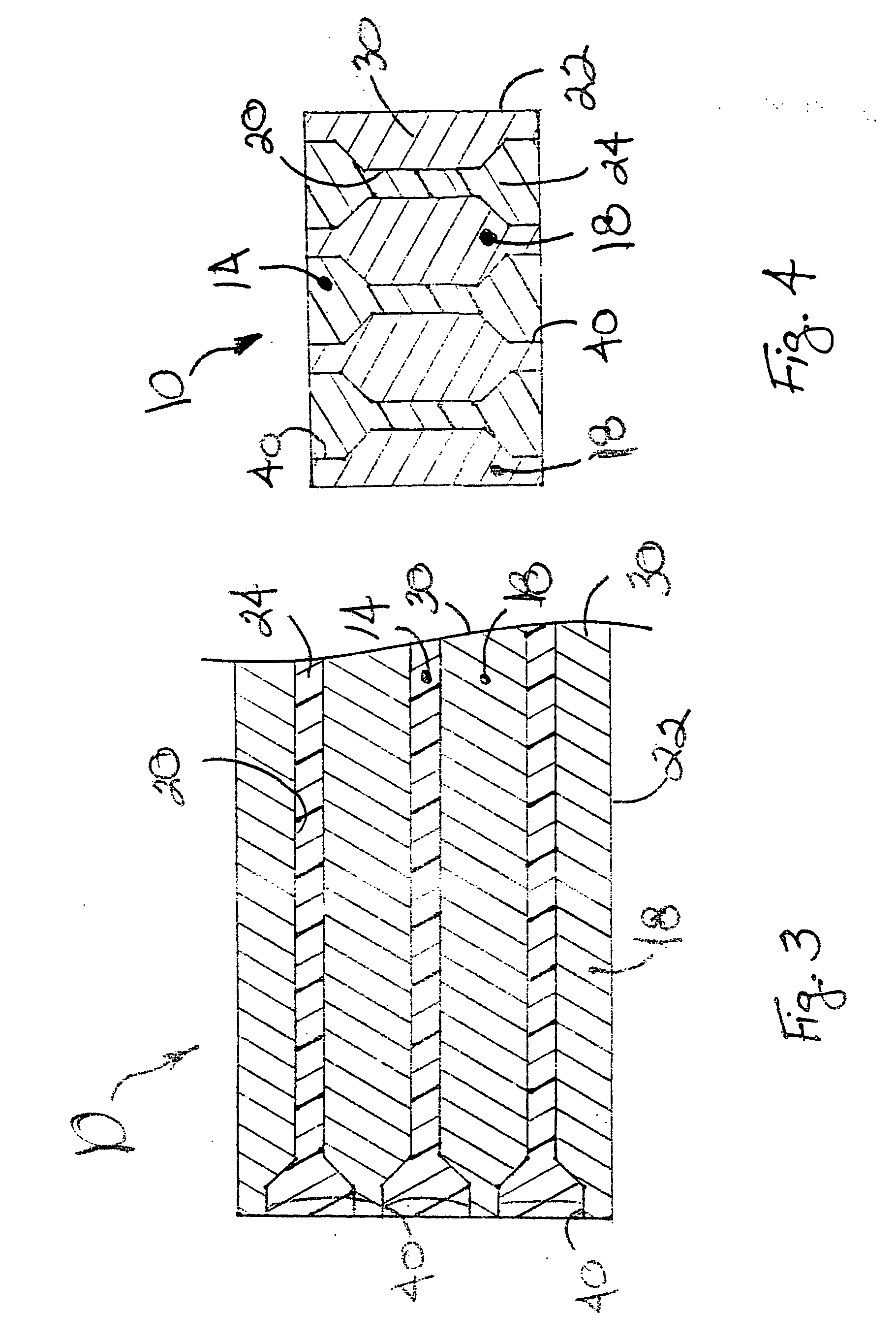

[0019] Referring now to the drawings, the details of preferred embodiments of the present invention are graphically and schematically illustrated. Like elements in the drawings are represented by like numbers, and any similar elements are represented by like numbers with a different lower case letter suffix.

[0020] As exemplified in the figures, the present invention is a non-detonable explosive scent training tool 10 for use as a scent source in the training of explosives detecting dogs. Generally, the present scent training tool 10 comprises an explosive material 14, an inert carrier medium 18 made from a relatively non-volatile material, and a plurality of sub-critical dimension receiver spaces 20 formed by or in the inert carrier medium 18. The sub-critical dimension receiver spaces 20 are “sub-critical” in that each defines a volume having at least one physical dimension T that is less than the critical thickness of the explosive material to be contained within the receiver spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com