Downshift control for automotive automatic transmission

a technology of automatic transmission and downshift control, which is applied in the direction of electric control, ignition automatic control, machines/engines, etc., can solve the problems of large-scale shift shock, instantaneous increase in engine braking, and time required for downshift to be increased, so as to eliminate or reduce the effect of downshift shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

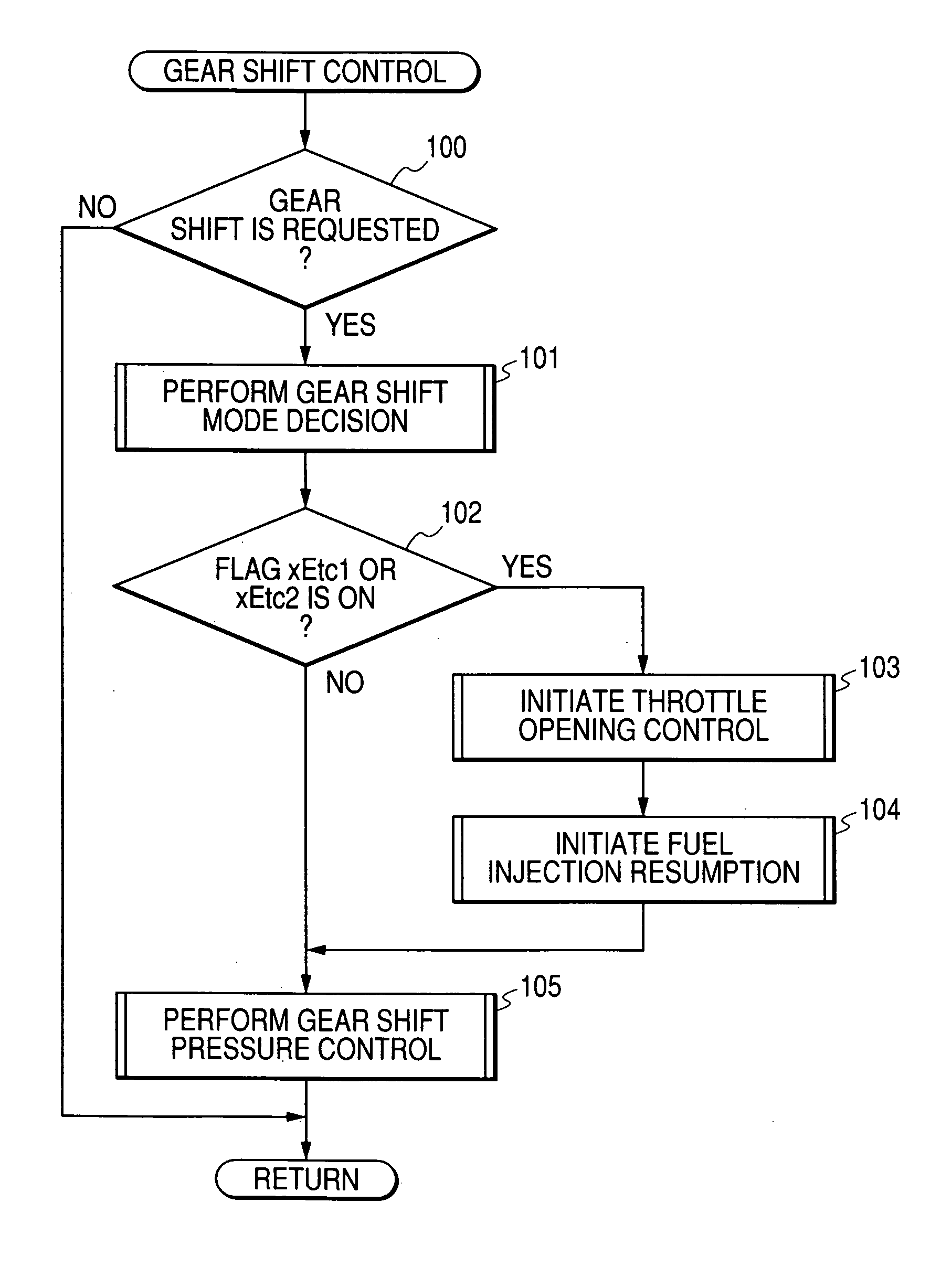

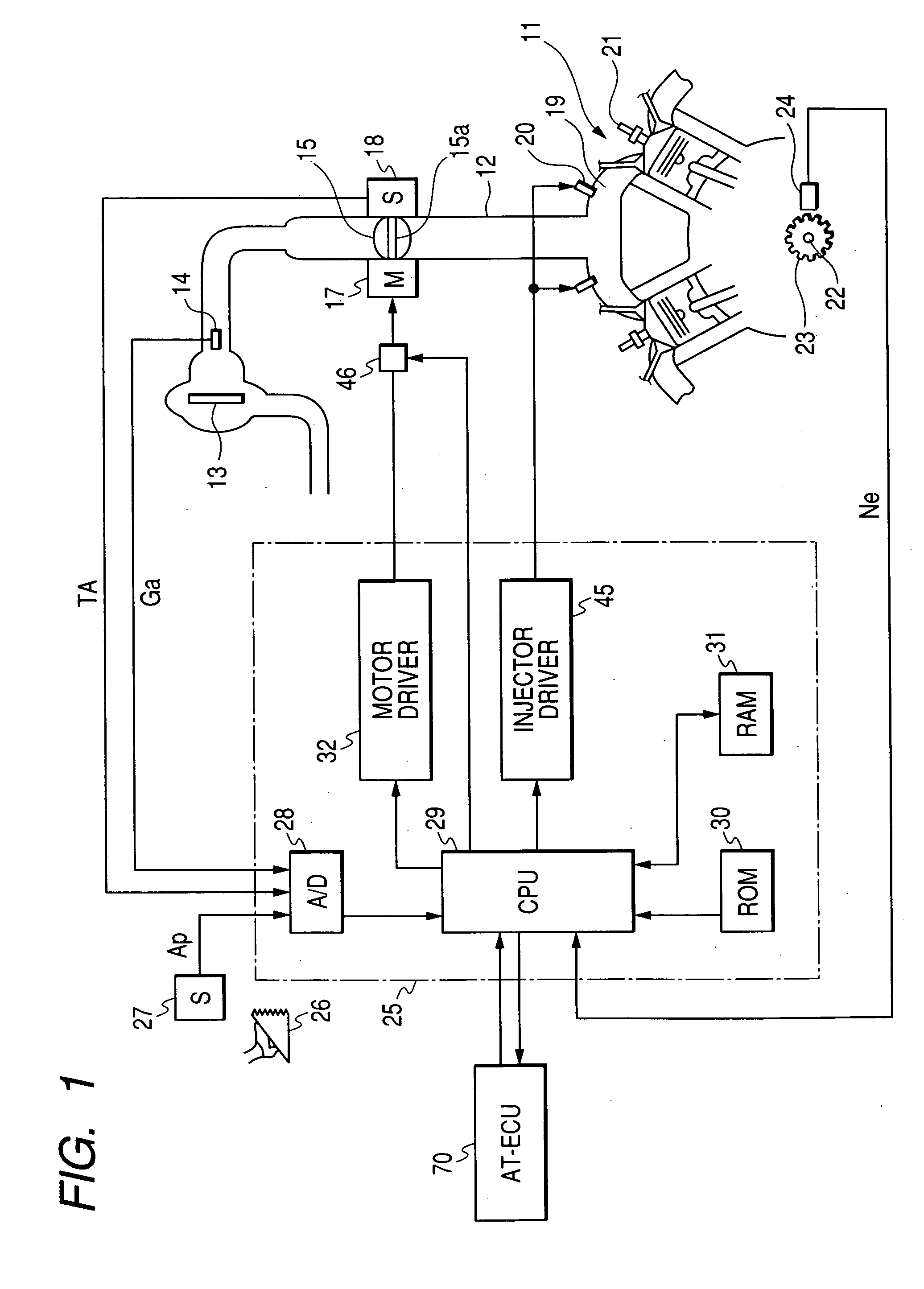

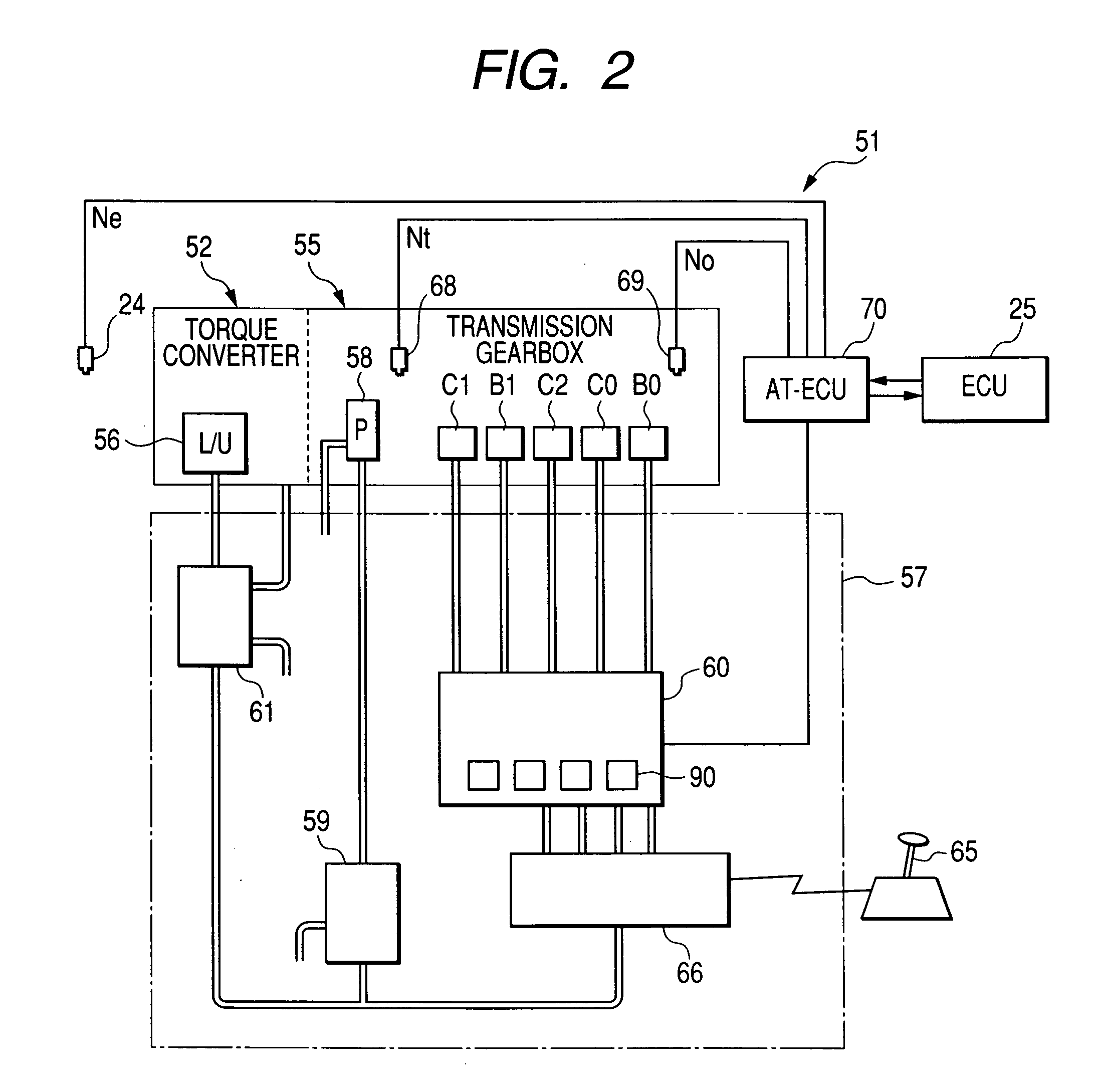

[0084] Referring to the drawings, wherein like reference numbers refer to like parts in several views, particularly to FIG. 1, there is shown an engine control system according to the invention which is designed to control an operation of an automotive internal combustion engine 11 and a downshift operation of an automatic transmission 51, as illustrated in FIG. 2, with aid of activity of an electronic throttle control (ETC) system.

[0085] The engine 11 is connected to an intake pipe 12. An air cleaner 13 is installed upstream of the intake pipe 12. An air flow meter 14 is disposed downstream of the air cleaner 13 which measures an intake air flow rate Ga. A throttle valve 15 is disposed downstream of the air flow meter 14. The throttle valve 15 has a rotating shaft 15a connected to an electric motor 17 such as a DC motor. The motor 17 works to control the position (i.e., the amount of throttle opening) of the throttle valve 15. A throttle position sensor 18 measures the position of ...

second embodiment

[0218] The engine control system of the second embodiment will be described below.

[0219] The engine control system of the first embodiment is designed to decide that a failure has occurred in the hydraulic pressure control for the automatic transmission 51 if an actual downshift is not detected when the elapsed time from the start of hydraulic pressure control has reached the failure decision time slightly longer than an expected time at which the automatic transmission 51 will initiate the downshift actually and immediately stop the engine output increasing control. The engine control system of the second embodiment is equipped with a hydraulic switch working to detect the fact that the hydraulic pressure acting on the off-going clutch lies within a lower range defined around the standby hydraulic pressure and designed to measure the elapsed time from the start of the hydraulic pressure control for a downshift, decide that a failure has occurred in the hydraulic pressure control wh...

third embodiment

[0223] The engine control system of the third embodiment will be described below.

[0224] If the hydraulic pressure acting on the off-going clutch fails to drop to within the lower range after the start of the hydraulic pressure control to make a downshift in the automatic transmission 51, it may result in an interlocking in which the hydraulic pressure applied to the off-going clutch fails to drop, and that applied to on-coming clutch arises, so that they are engaged simultaneously. If such an interlocking is taken place upon downshifting of the transmission gearbox 55, it will, as demonstrated in FIG. 29, result in a drop in the input shaft speed Nt or the output shaft speed No of the transmission gearbox 55 due to deceleration of the vehicle.

[0225] The engine control system of the third embodiment is designed to inhibit the engine output increasing control using the above event. Specifically, the engine control system works to decide that the interlocking between the on-coming and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com