Coated solder spheres and method for producing the same

a technology of solder spheres and solder spheres, which is applied in the direction of soldering apparatus, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of blackening of solder spheres, and achieve the effect of low slip properties and good slippag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0030]Solder spheres of an Sn—Pb eutectic alloy having a diameter of 0.76 mm were dipped into a solution of stearamide (a fatty acid amidamide lubricant) dissolved in methylene chloride to give a concentration of 50 ppm, 500 ppm, or 1000 ppm. The solder spheres were collected by centrifugation and dried by volatilizing the solvent in a moisture controlled chamber, leaving solder spheres having a substantially uniform coating of stearamide on the surfaces thereof.

[0031]The resulting coated solder spheres and uncoated or bare solder spheres used as controls were subjected to a blackening test, a placement test, and a soldering test in the following manner.

Blackening Test

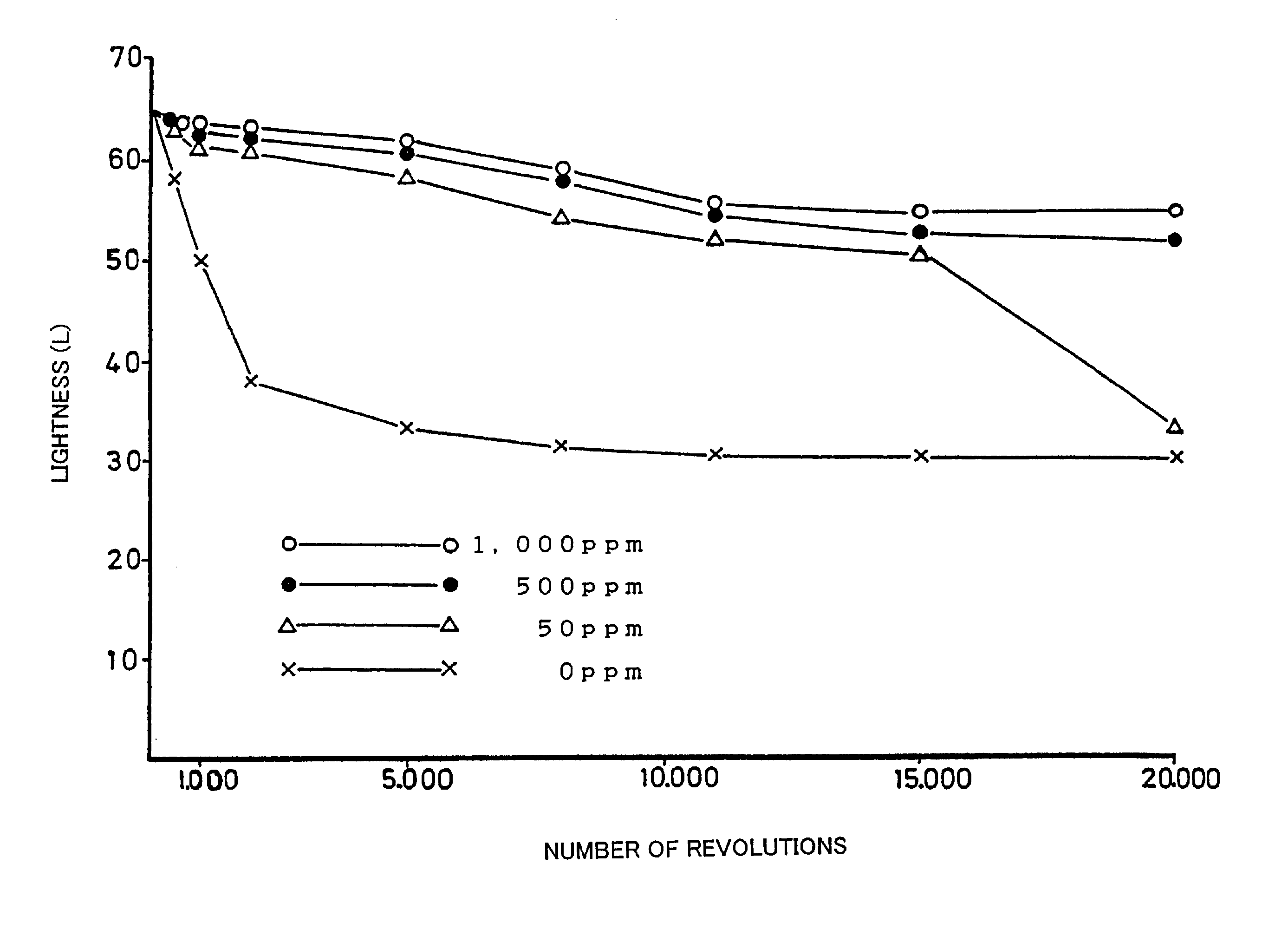

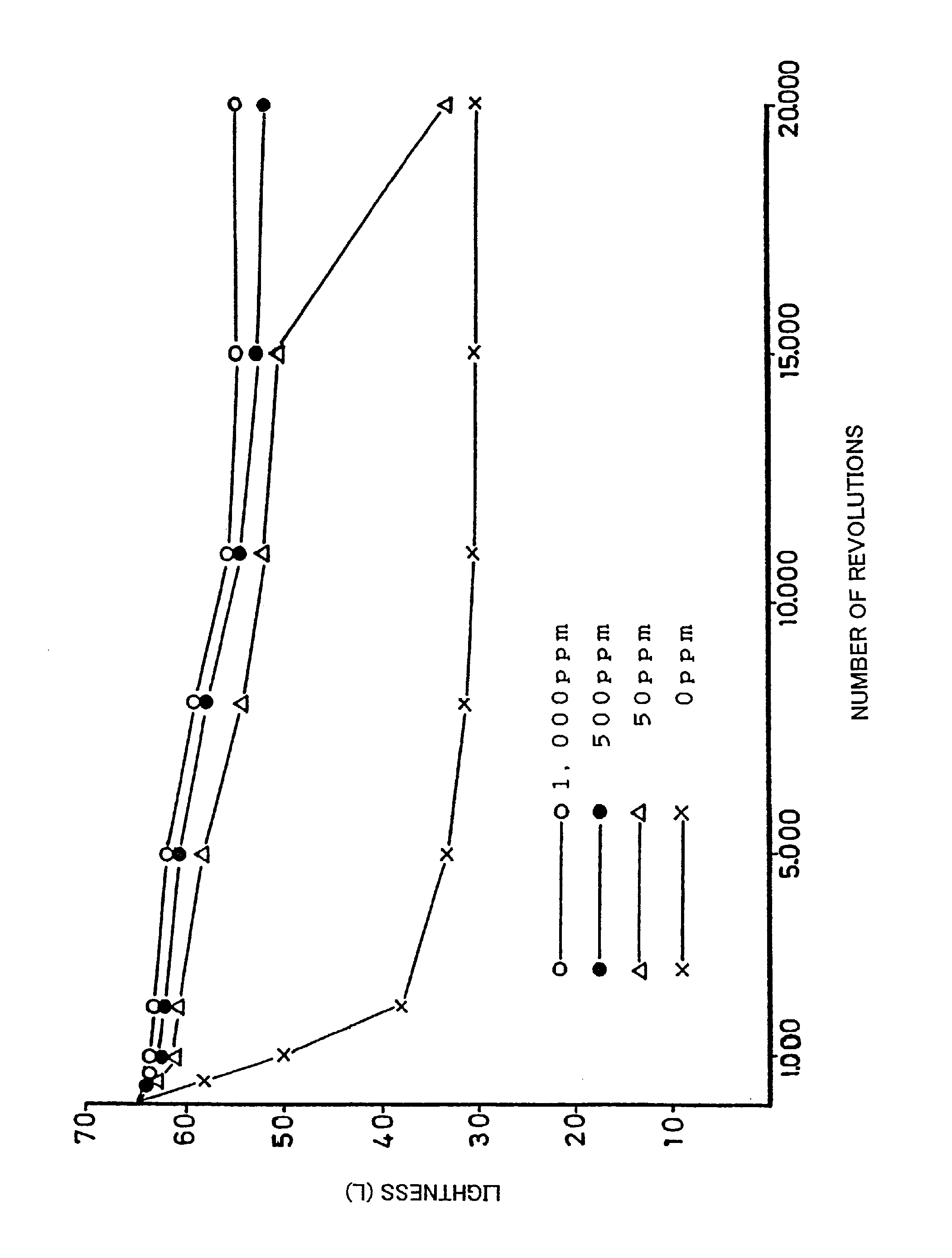

[0032]A 50 cc glass bottle was packed with 40 grams of the solder spheres to be tested. After the bottle was closed with a plastic cap, it was rotated at a rate of 60 rpm using a horizontal spindle holding the bottle in a vertical position until the number of revolutions reached a predetermined value. Thereafter, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com