Three-dimensional confocal microscope

a confocal microscope and three-dimensional technology, applied in the field of three-dimensional confocal microscopes, can solve the problems of inability to correctly observe, unstable surface of sample, adverse vibrations affecting observation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

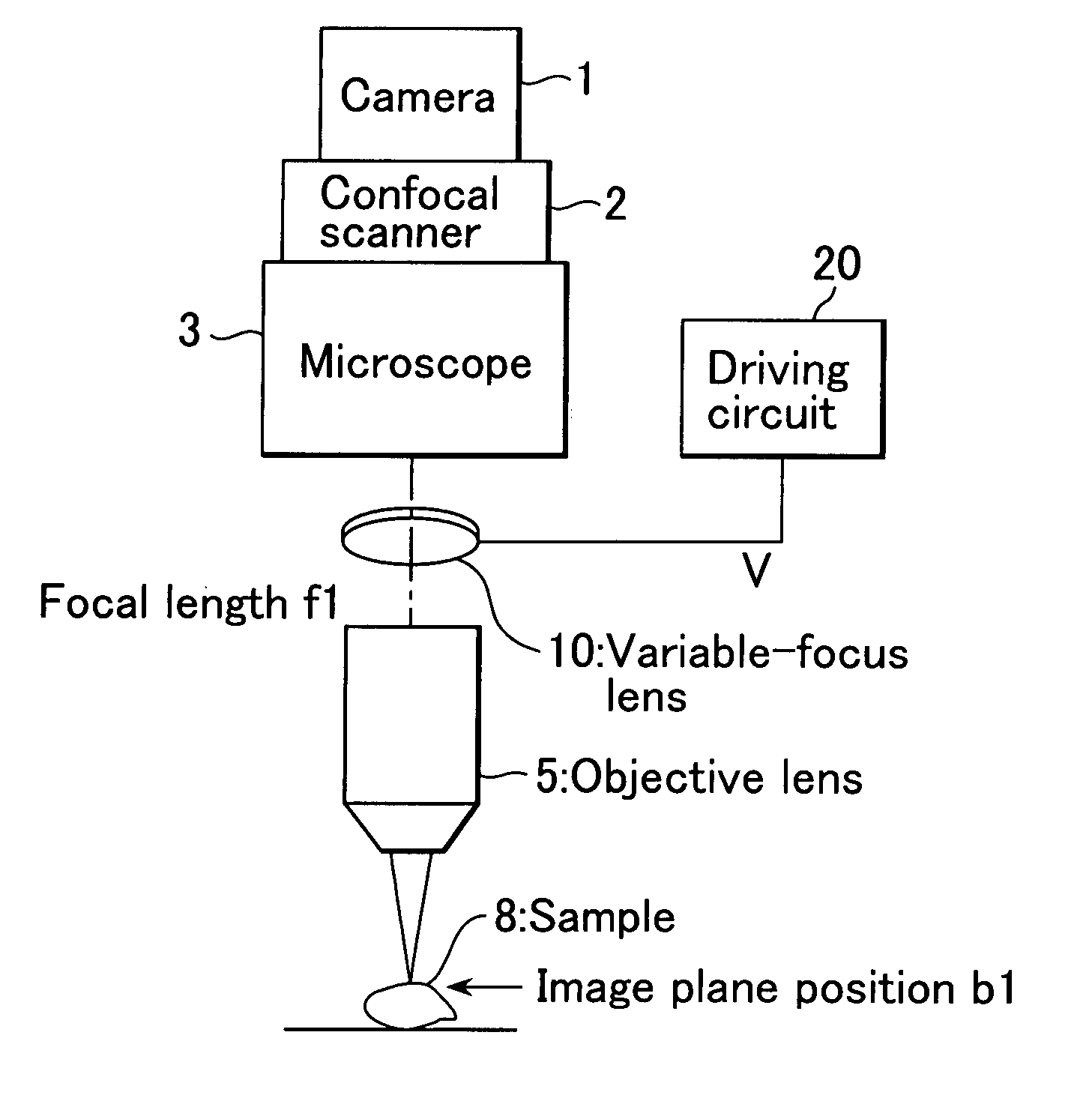

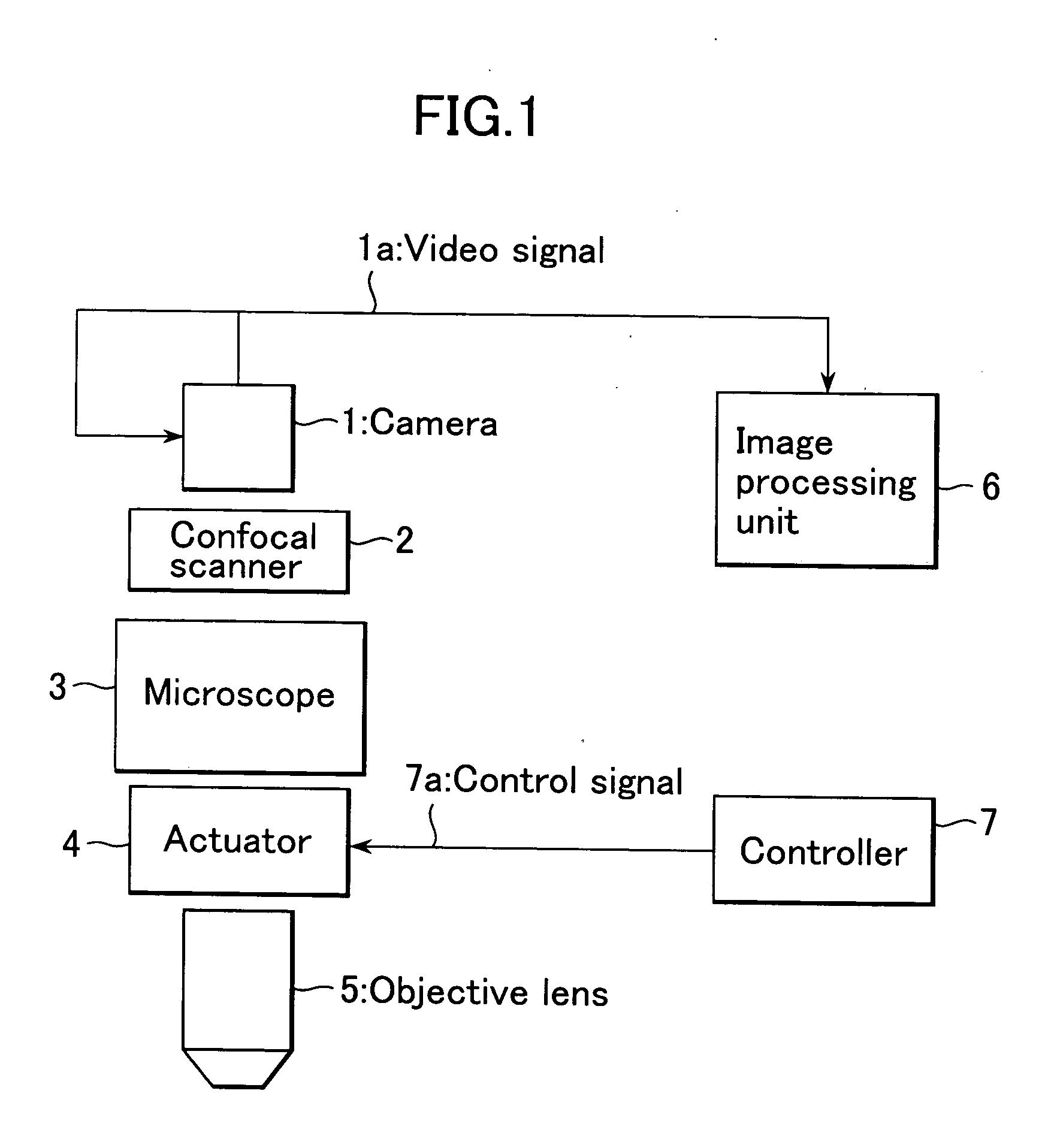

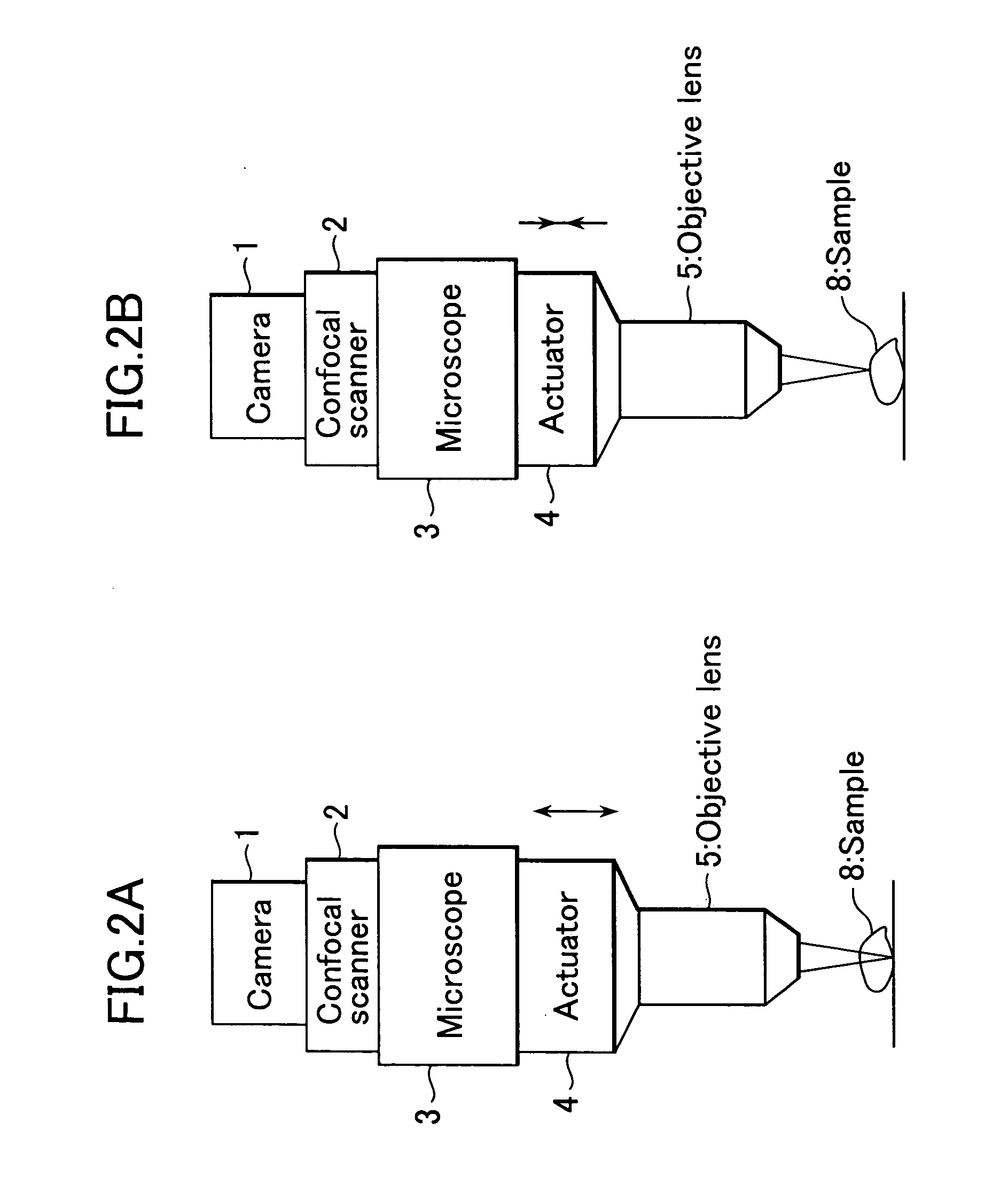

[0019] Hereinafter, this invention will be described in detail with reference to the drawings. FIGS. 3A and 3B are block diagrams showing an embodiment of a three-dimensional confocal microscope according to this invention. In this embodiment, since processing of an image picked up by a camera 1 is not directly related to this invention, the image processing unit of this invention, equivalent to the image processing unit 6 shown in FIG. 1, will not be shown in the drawings and will not be described in detail.

[0020] In FIGS. 3A and 3B, parts equivalent to those in FIG. 1 are denoted by the same numerals. FIGS. 3A and 3B differ from FIG. 1 in that a variable-focus lens of surface tension control type 10 and a driving circuit 20 are used instead of the actuator and the controller. The variable-focus lens of surface tension control type (hereinafter simply referred to as variable-focus lens) 10 is used as a field lens.

[0021]FIG. 4 shows a theoretical structural view (cross-sectional v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com