Methodology and apparatus for storing and dispensing liquid components to create custom formulations

a technology for liquid components and custom formulations, applied in liquid transferring devices, packaging goods types, transportation and packaging, etc., can solve the problems of physical tax on the operator, drawbacks and disadvantages of manual methods of dispensing formulations, and the most costly expense of operator handling in creating custom formulations, so as to reduce the amount of base materials and reduce material opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

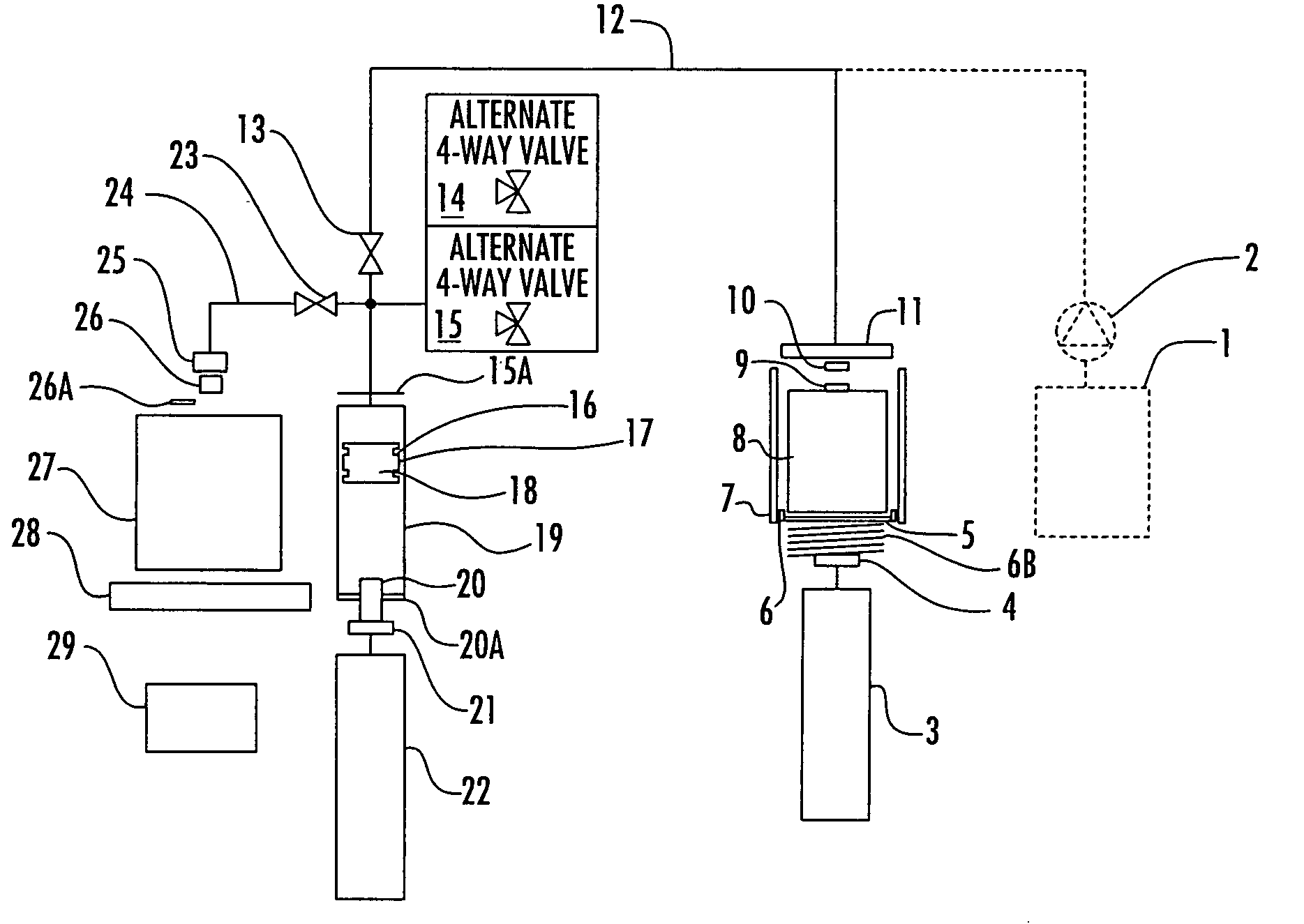

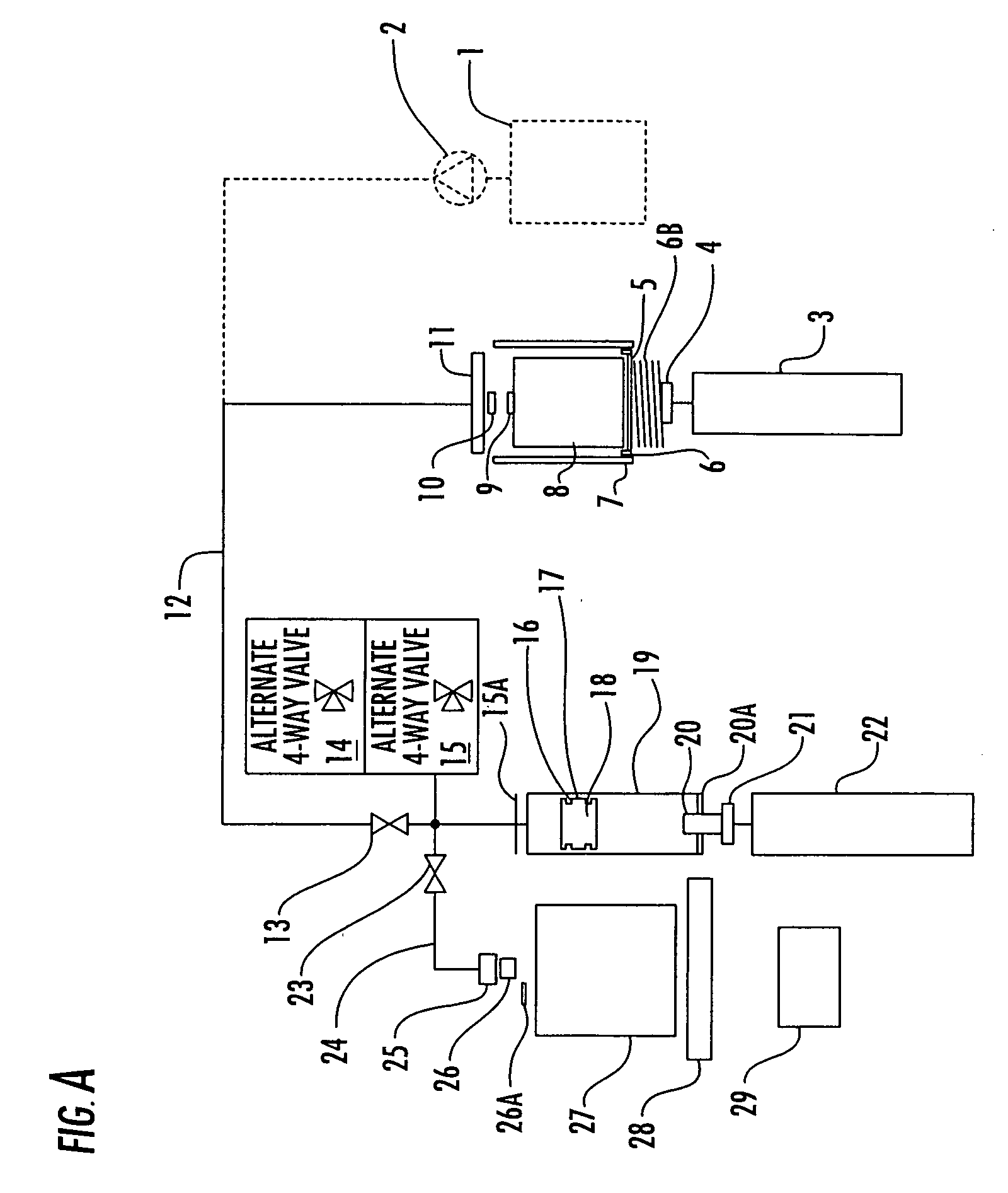

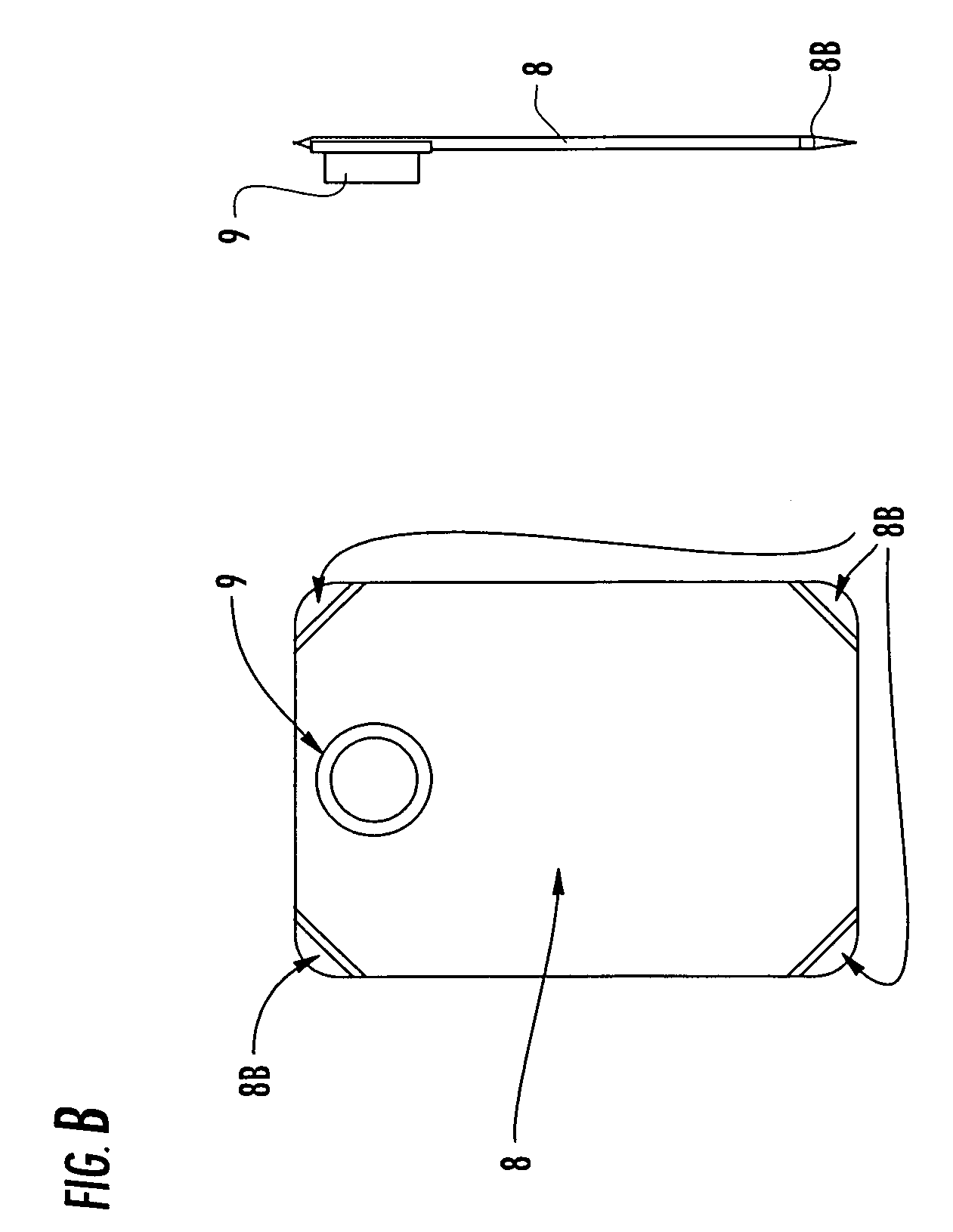

[0056] The present invention may be embodied in many forms and many methodologies. As used herein, the following terms have the following broad meaning as understood by those of skill in the art. Note that these definitions are intended to simply assist the reader in understanding the terms used herein and are not meant to provide a limiting definition to each term. The term “material” means a flowable, non-solid substance, such as liquid, paste or powder, or any other substance capable of dispensing. The term “formulation” means a prescribed recipe of a number of material components typically divided, according to their individual requirements, by percentages that, when dispersed or thoroughly mixed together, create a desired finished product. The terms “container” or “material container” mean any and all devices or structures, in which one or more materials may be contained, held, packaged into, received in, stored in or used as delivery package, including without limitation any a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com