Apparatus and methods for reducing stand-off effects of a downhole tool

a technology of stand-off effects and tools, applied in the field of tools for well logging, can solve the problems of difficult or impossible analysis of desired signals, difficult or impossible measurement, and the environment is extremely harsh, and achieve the effect of reducing the thickness of the mud layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

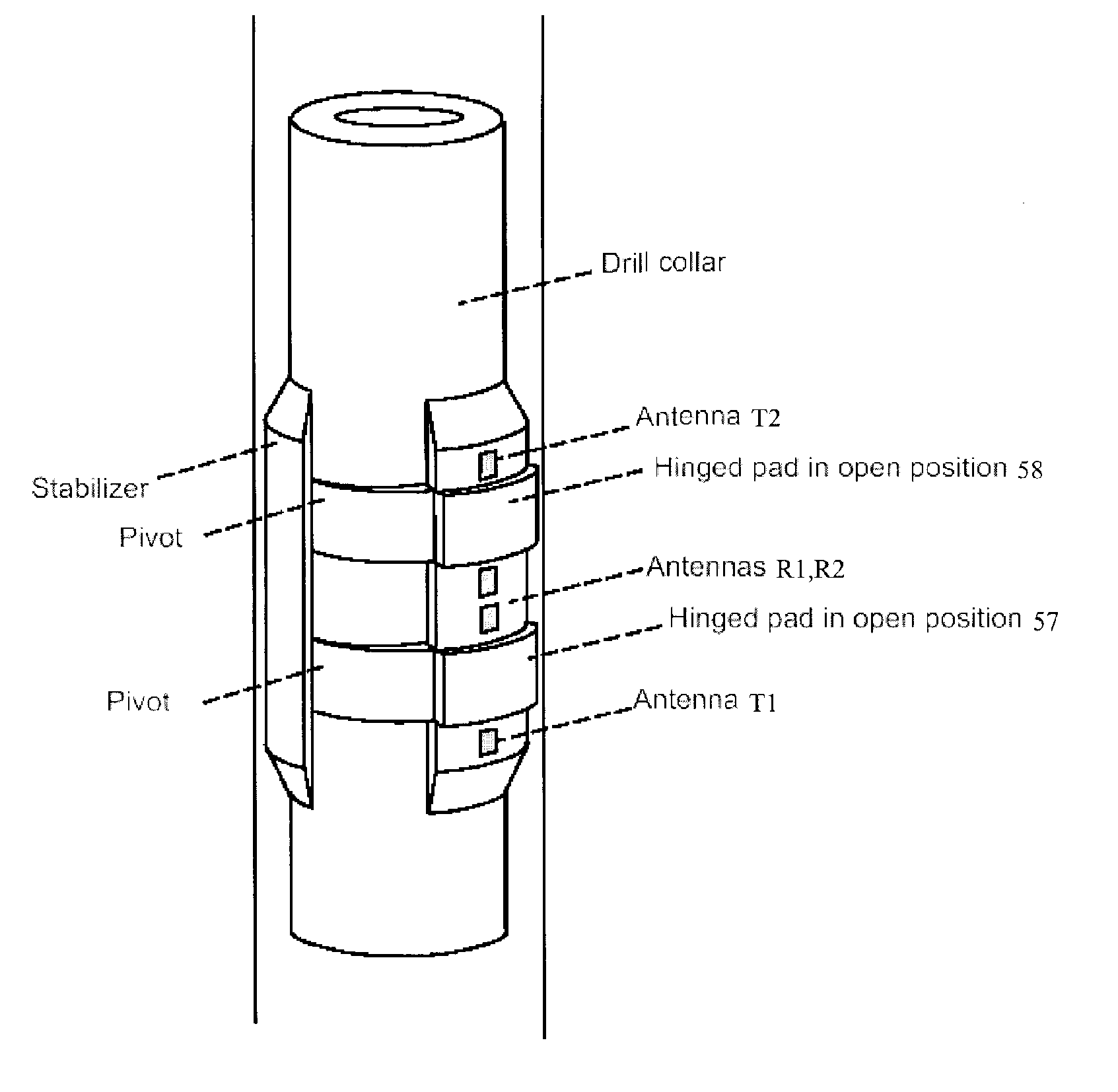

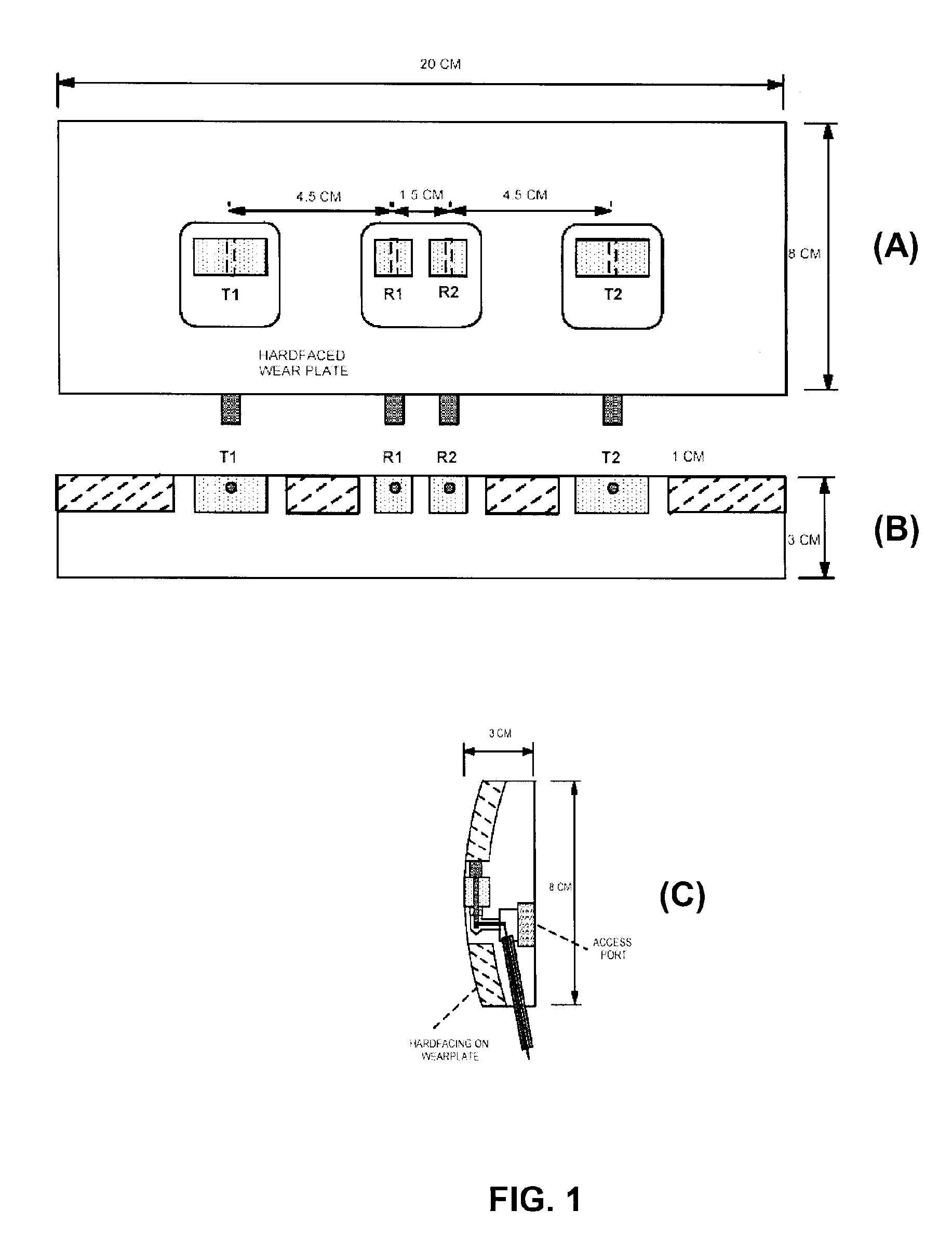

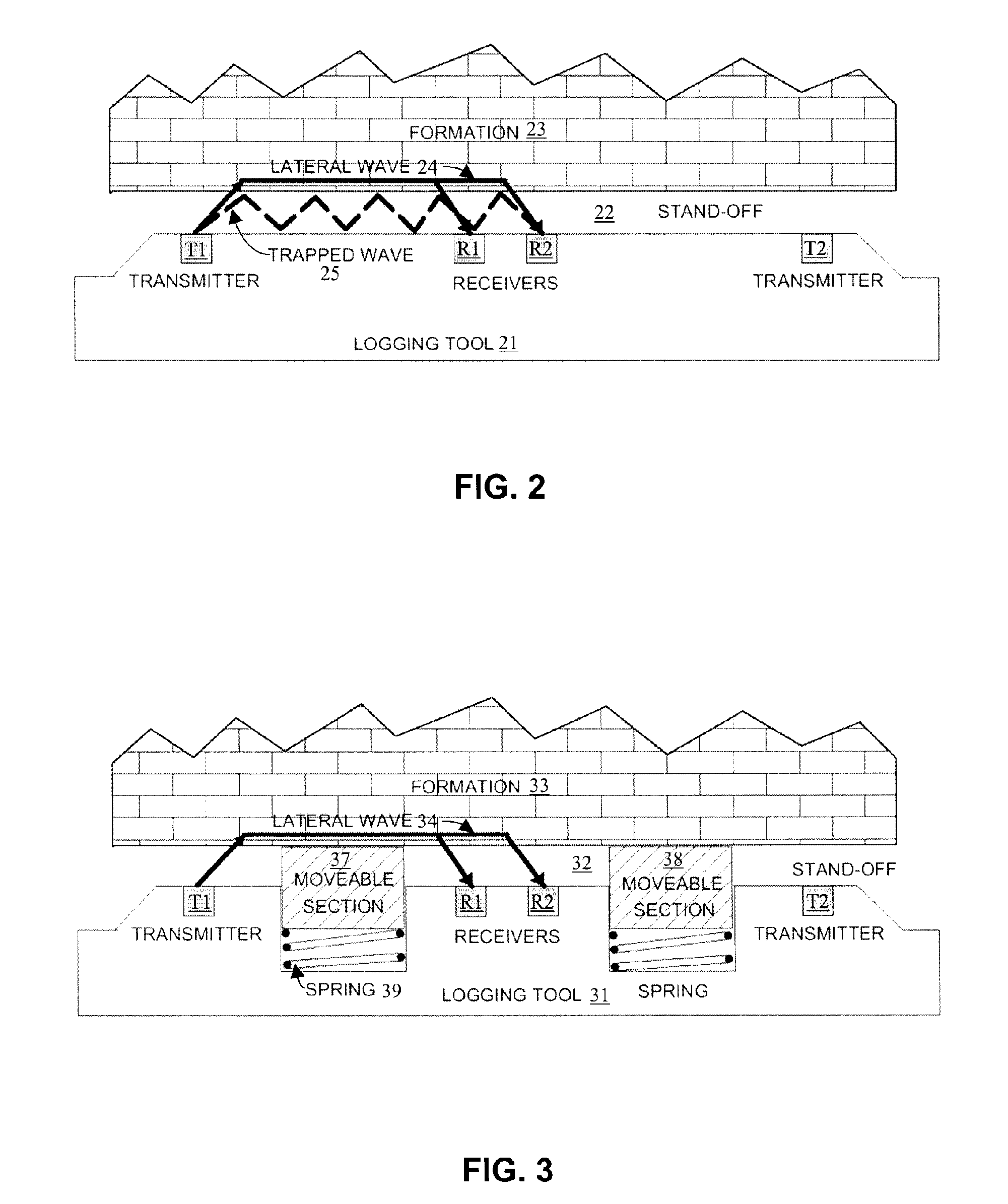

[0029] Embodiments of the invention relate to methods for reducing stand-off effects without mounting sensors (e.g., antennas) on articulated pads. In accordance with embodiments of the invention, the sensors or antennas (e.g., transmitters and receivers) may be mounted on the drill collars or stabilizers of a tool, and one or more articulating (deployable) pads are placed between the energy source (e.g., transmitters) and detectors (e.g., receivers). These pads may be articulated to eliminate or minimize the mud layer between the pads and the formation, and, therefore, to eliminate or minimize the transmission of the trapped signals. Embodiments of the invention is based on the concept of divorcing the sensors (e.g., antennas) from the articulated pad, while retaining the advantages of articulation.

[0030] Embodiments of the invention may be applied to any sensor or tool that is adversely impacted by trapped signals traveling in a mud layer between a source and a receiver. Such sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com