Flexible hydrogen delivery mechanism for storage and recovery of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

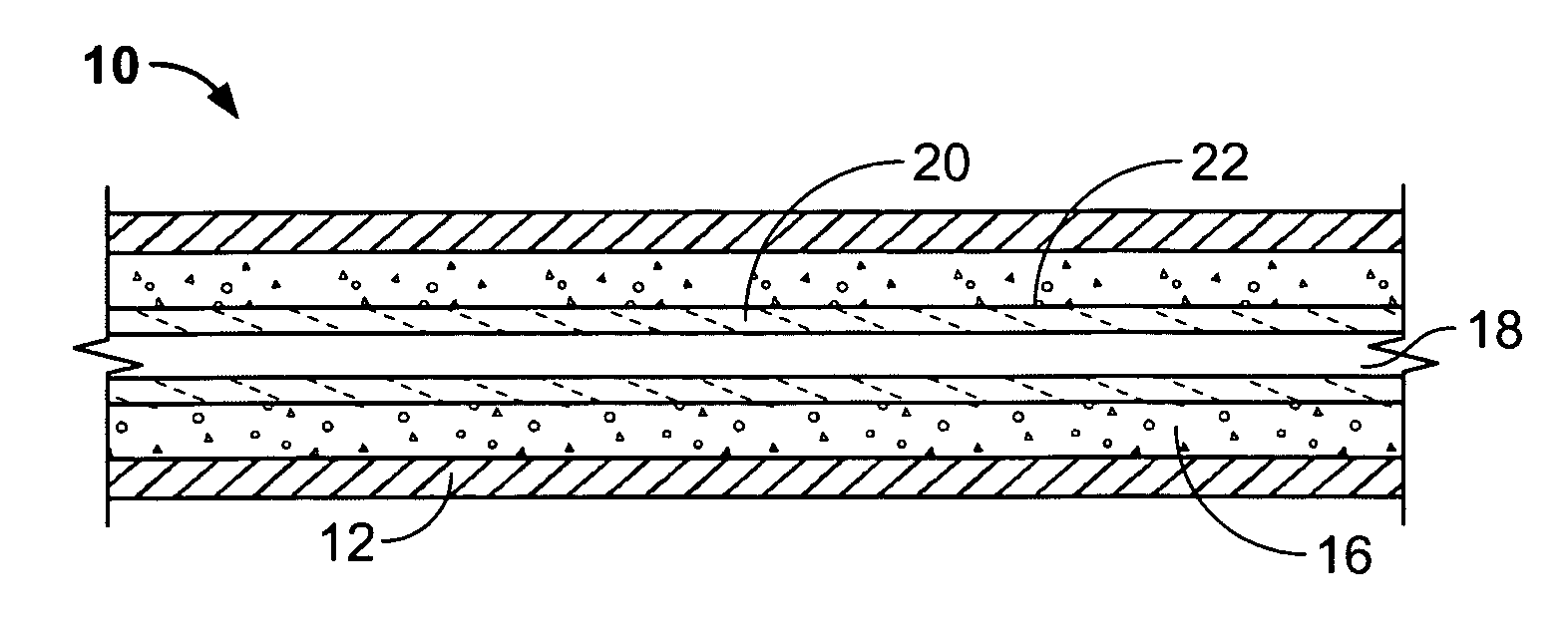

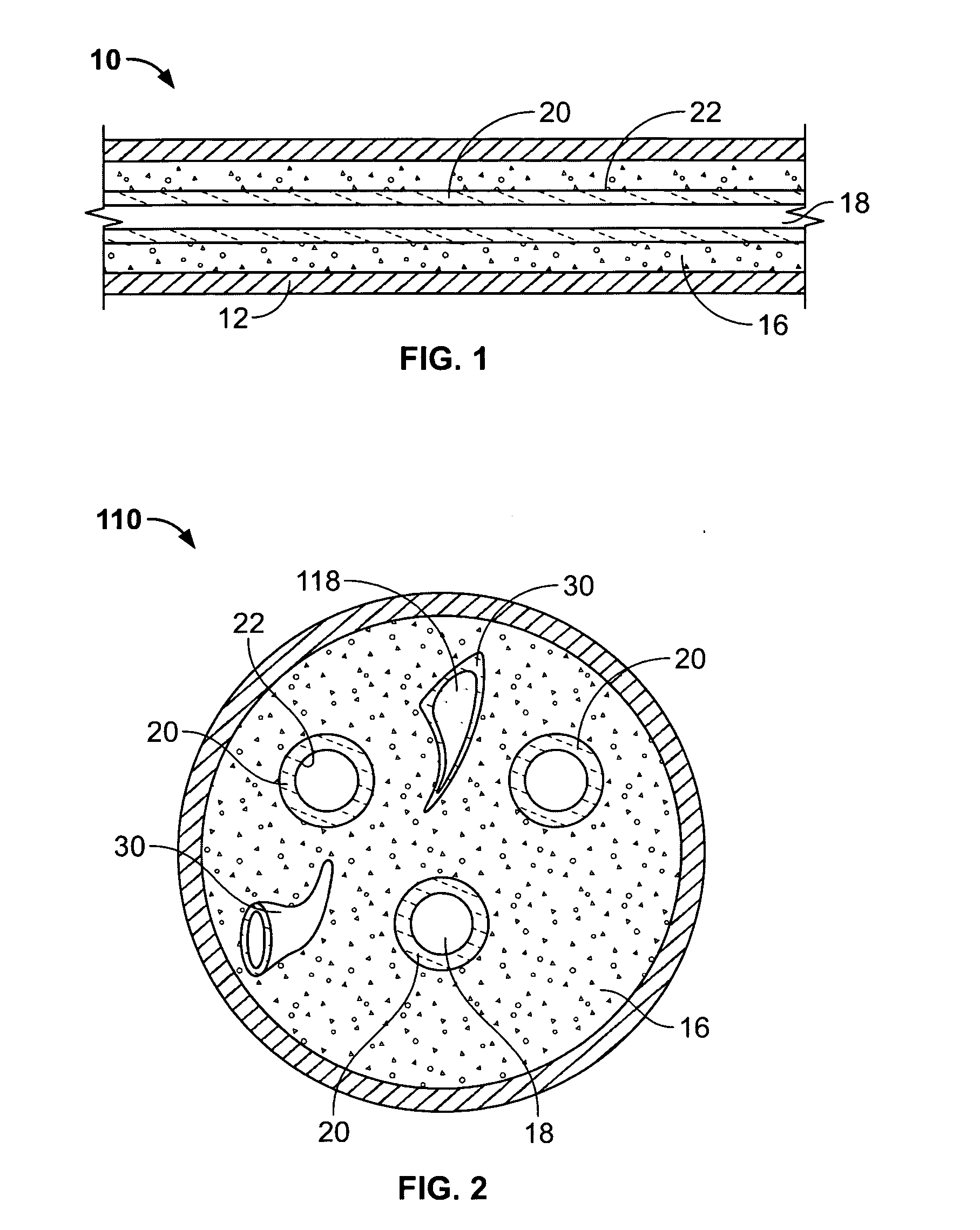

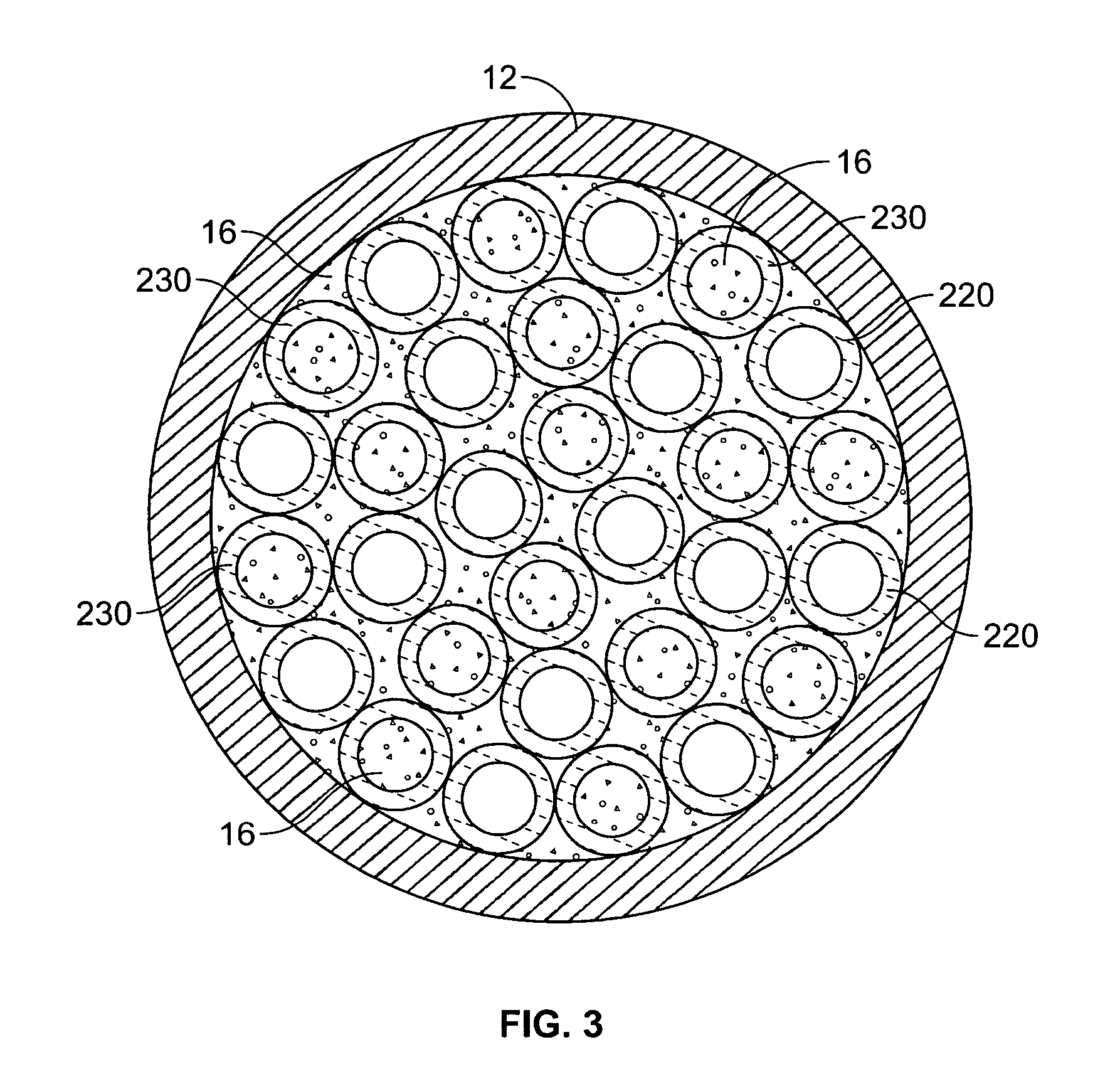

[0016] Referring now to FIG. 1, a generally tubular compartment unit 10 having a tubular wall 12 is shown in cross-section. For a more detailed description of the structure of the unit 10, including tubular walls 12, and the hydride material 16 contained by the wall 12, reference is made to the description found in commonly-owned U.S. Pat. No. 4,396,114, which description is incorporated herein by reference.

[0017] One significant difference from U.S. Pat. No. 4,396,114, providing a marked improvement and important feature of the present invention, is the ability to miniaturize the tubular unit 10, while simultaneously providing fluid communication within and through the tubular unit 10 so as to evenly distribute the hydrogen gas throughout the hydride material 16, along the entire length of the tubular unit. It has been suggested to use flexible helically wound springs, axially extending throughout the tubular unit 10. While the use of such closely wound springs to provide central ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com