Golf ball

a golf ball and ball technology, applied in the field of golf balls, can solve the problems of not reducing aerodynamic resistance so effectively, and achieve the effect of improving aerodynamic performance and long flying distan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

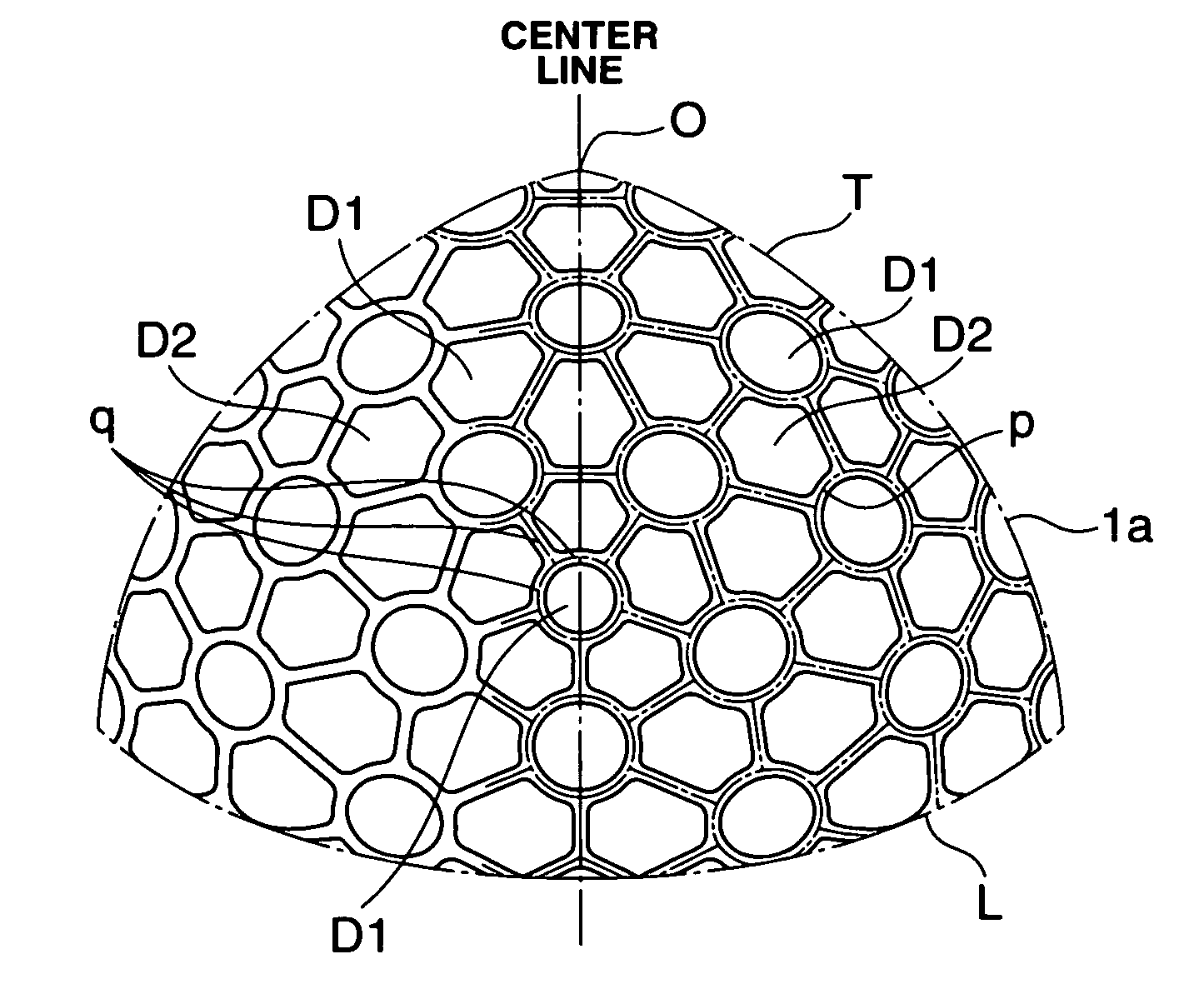

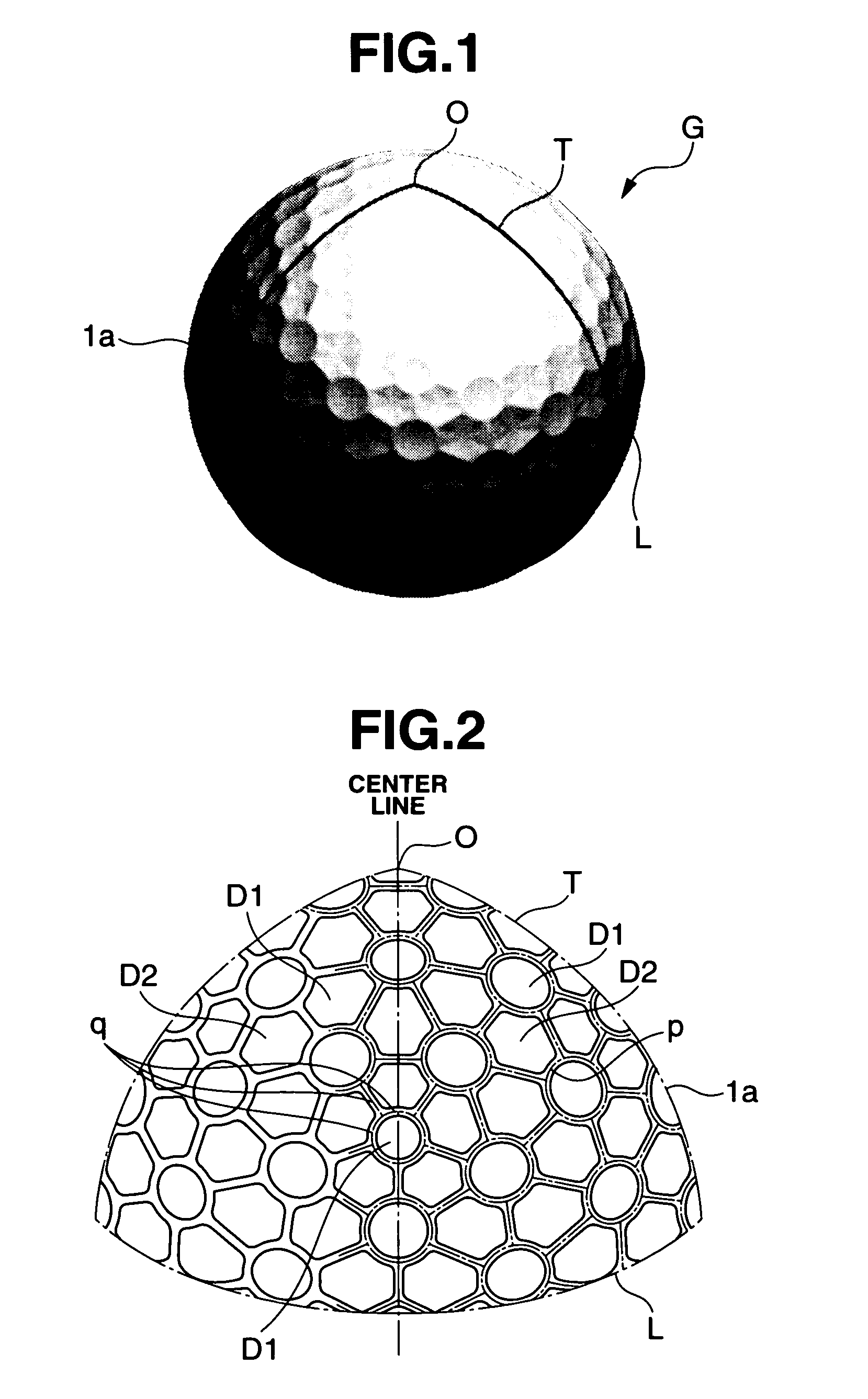

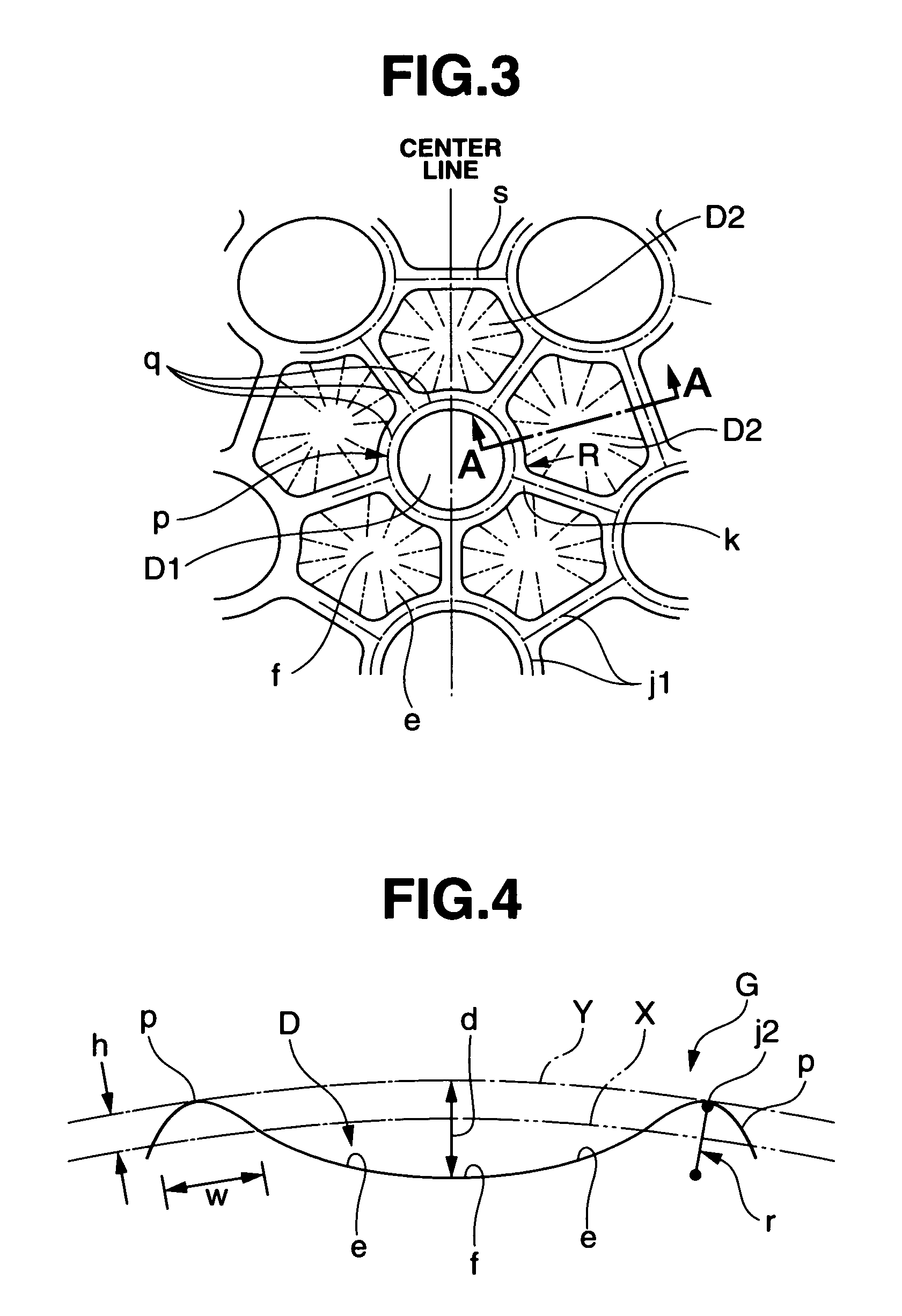

[0040] The invention will be described with reference to the following Examples and Comparative Examples, which are not intended to restrict the scope of the invention. Example 1 and Comparative Examples 1 and 2 Golf ball samples were prepared, each having dimples arranged as shown in FIG. 1 (Example 1), FIG. 6 (Comparative Example 1), and FIG. 7 (Comparative Example 2). They were tested for flight performance. Dimples are arranged on the spherical surface divided into six sectors (in Example 1 and Comparative Example 1) or icosahedron (in Comparative Example 2).

[0041] The golf ball samples in these examples are of three-piece structure consisting of a core (1), a cover (3), and an intermediate layer (2), as shown in FIG. 5. The details of each constituent are given below.

Core

[0042] The core was formed from a rubber composition composed of the following components. [0043] Polybutadiene (100 pbw), “BR01” from JSR. [0044] Zinc acrylate (25 pbw). [0045] Dicumyl peroxide (0.8 pbw), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com