Stereolithographic apparatus

a technology of stereolithography and lithography chamber, which is applied in the field of stereolithography chamber, can solve the problems of system difficulties, shrinkage, resolution, accuracy, etc., and achieve the effects of easy and fast changing of resin vats, simple resin vats, and easy change over of resin vats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

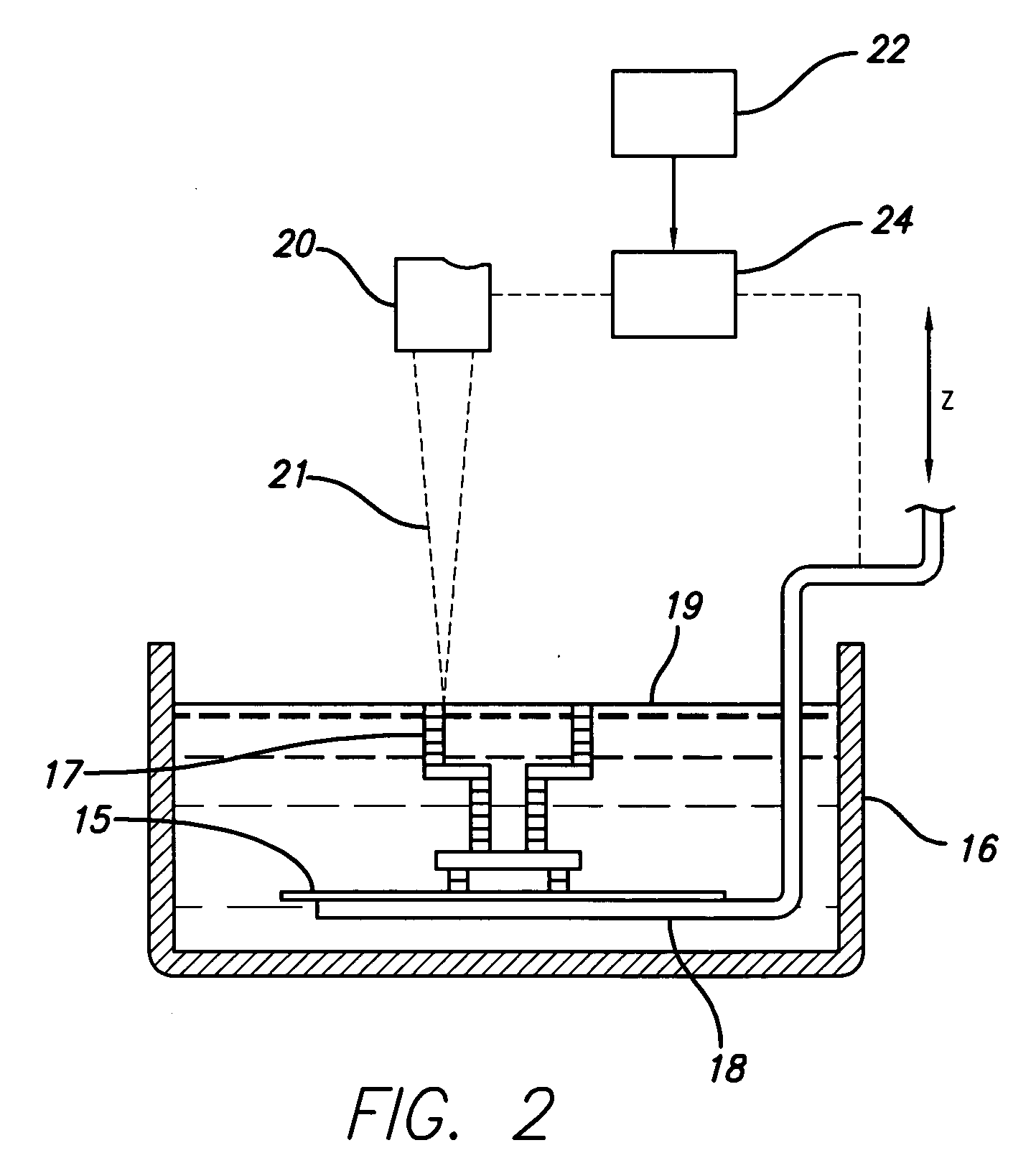

[0027] Stereolithography typically involves the layer by layer build-up of articles from a vat or container of liquid monomer. Stereolithography parts are preferably built on structures known as supports rather than directly on an elevator platform that moves the build object or part up and down as successive layers or laminae are formed during the stereolithography process. The vat of liquid photopolymer material provides a fresh material to create new layers as the object is built.

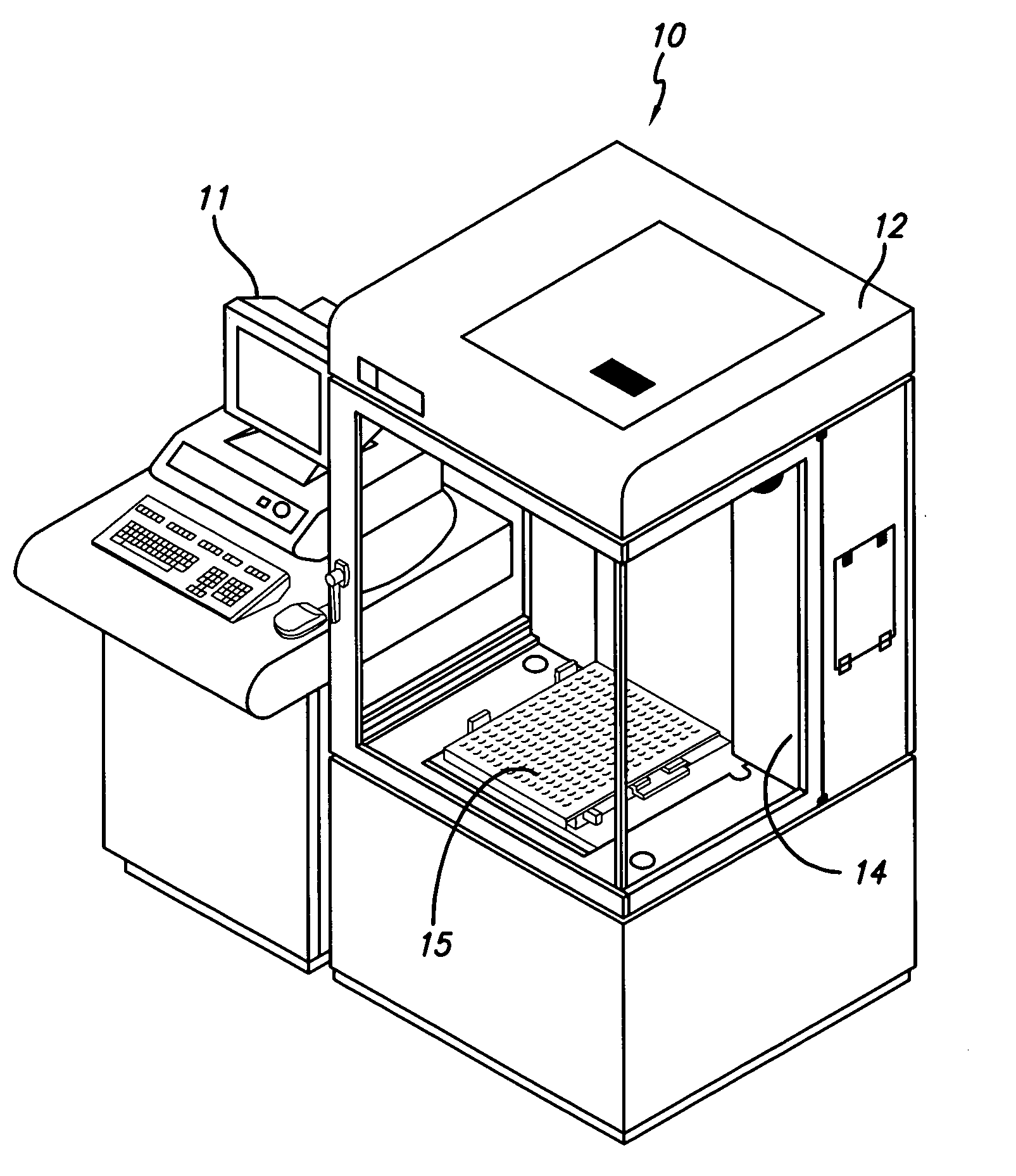

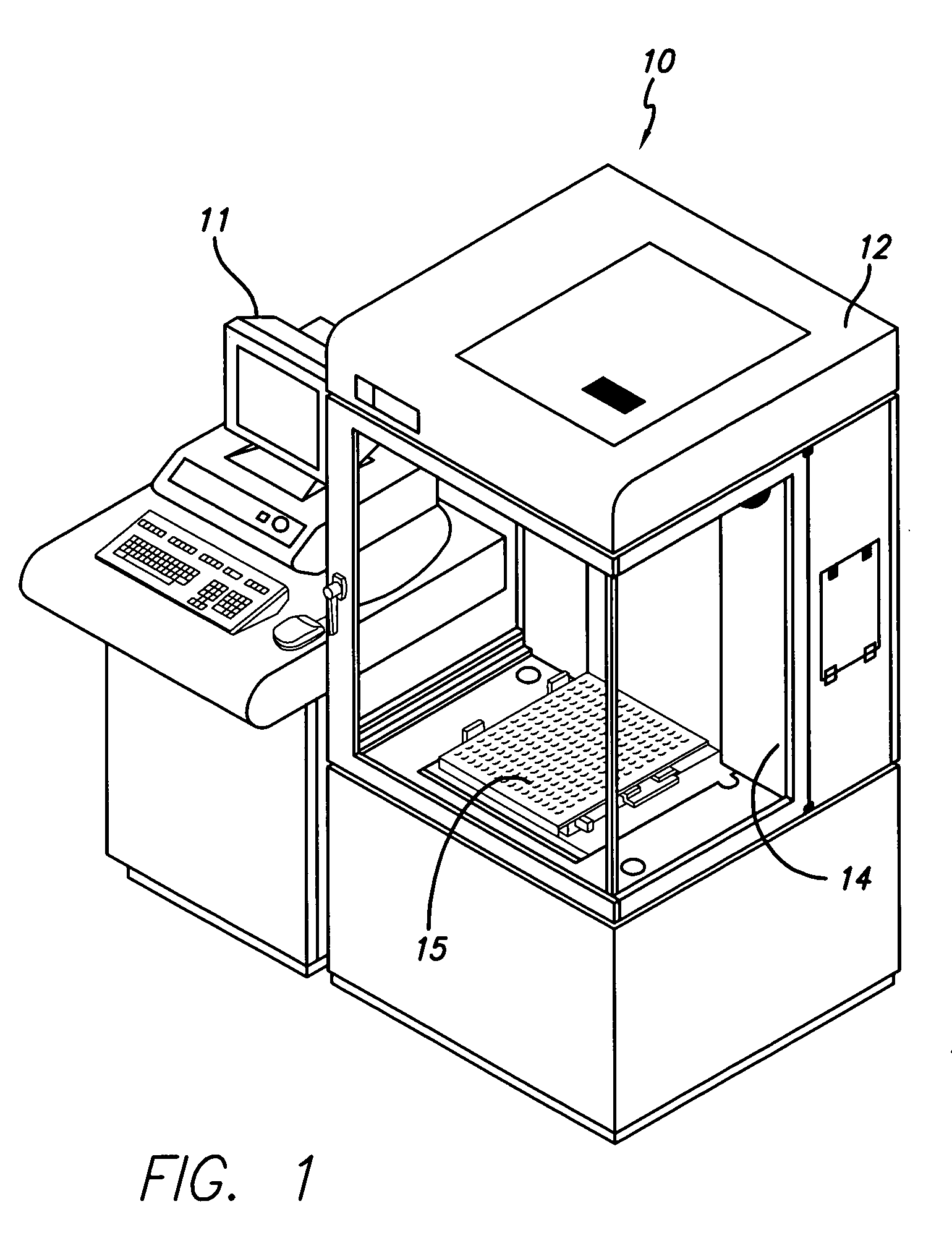

[0028] A typical stereolithography system is represented by the numeral 10 shown in FIG. 1. Such a system is offered commercially by 3D Systems, Inc. of Valencia, Calif. as the Viper Si2™ SLA® system. The system 10 includes a computer console 11 with a control computer, computer terminal, and monitor. The system 10 also has a laser housing 12 that includes a laser, mirrors, crystal and other components of the laser system of the type described in U.S. Pat. No. 6,157,663 to Wu et al. and assigned to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| processing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com