Electric drive system for vehicle, electric control system for vehicle, electric drive method for vehicle

a technology of electric control system and electric drive method, which is applied in the direction of electric propulsion mounting, battery/cell propulsion, transportation and packaging, etc., to achieve the effect of improving driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

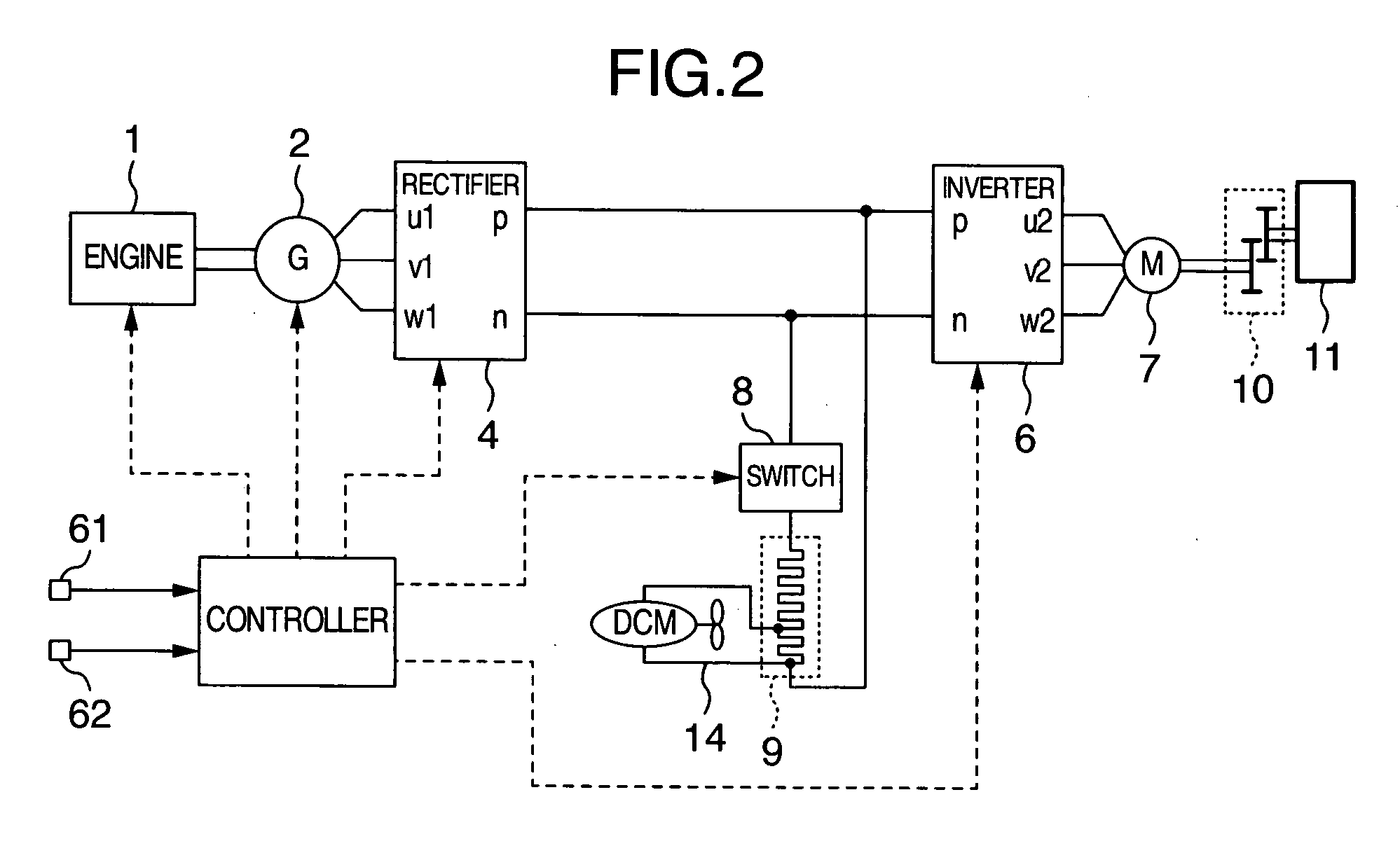

[0018] In the following, several embodiments of the present invention will be described with reference to the accompanying drawings.

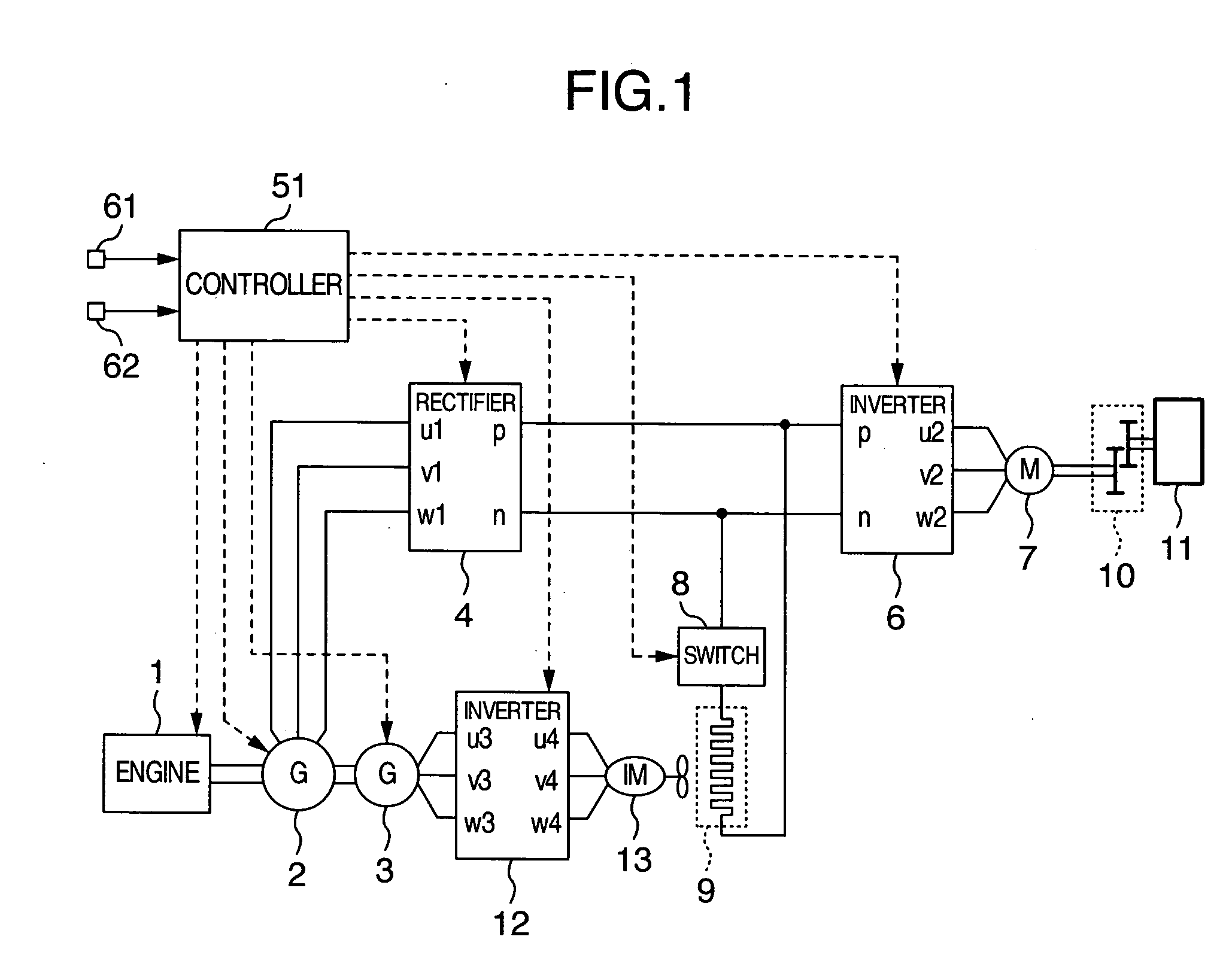

[0019] Describing in brief the configuration of an electric drive system for a vehicle according to a first embodiment, the electric drive system comprises a blower for cooling down a retard resistor in this embodiment. The blower is driven by an associated inverter which is powered by an auxiliary alternator coaxial with a main alternator. Also, the auxiliary alternator is controlled to generate a constant output voltage irrespective of the engine rotation speed, so that the retard resistor can be cooled down under an optimal cooling condition, irrespective of the engine rotation speed and conditions under which the main alternator generates the electric power.

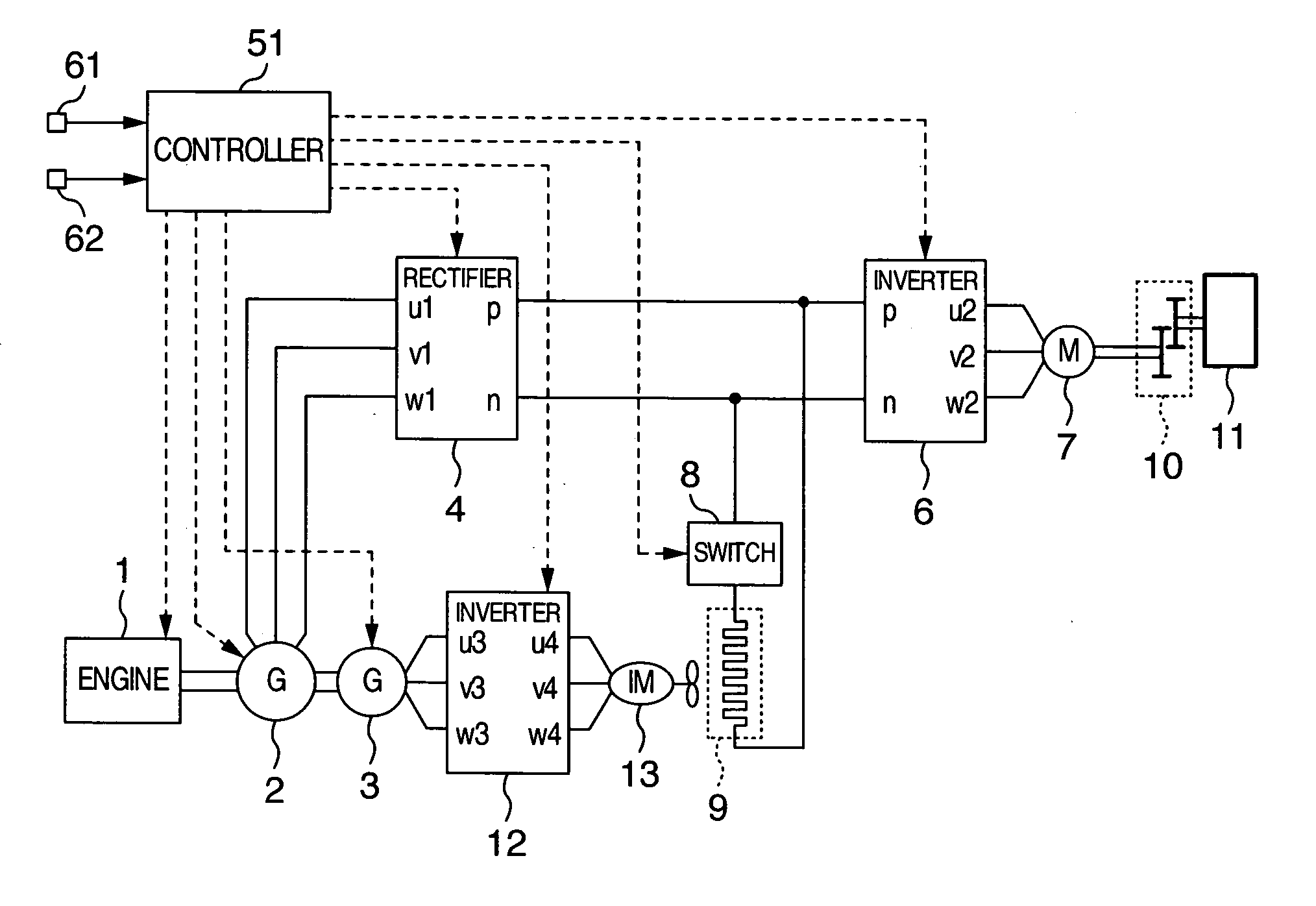

[0020] Describing specifically with reference to FIG. 1, the main alternator 2 and auxiliary alternator 3 are driven by the engine 1. The output of the main alternator 2 is converted to a direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com