Iridium oxide nanostructure patterning

a technology of patterned iridium oxide and nanowires, which is applied in the field of integrated circuit (ic) fabrication, can solve the problems of inability to form or template metallic nanowires without the use of porous material forms or templates, and add a considerable degree of complexity to the process, and achieve the effect of efficient formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

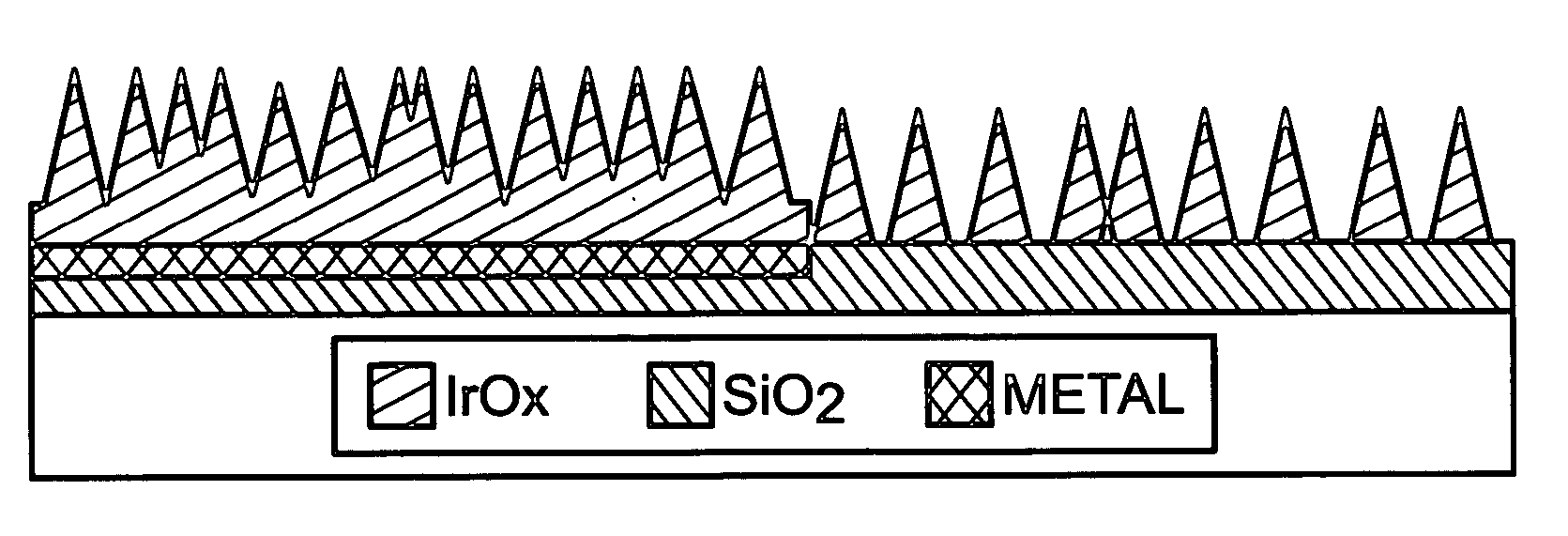

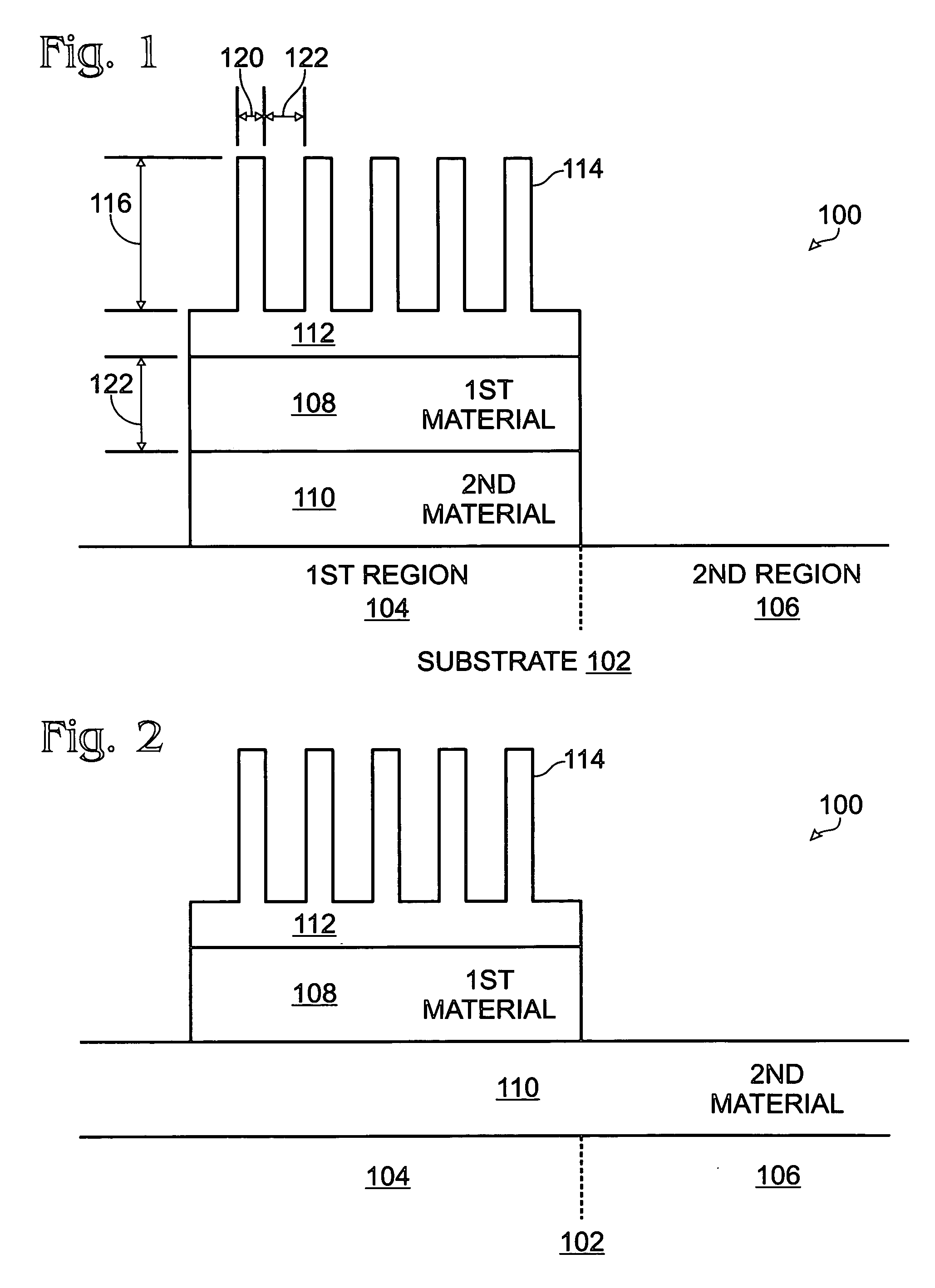

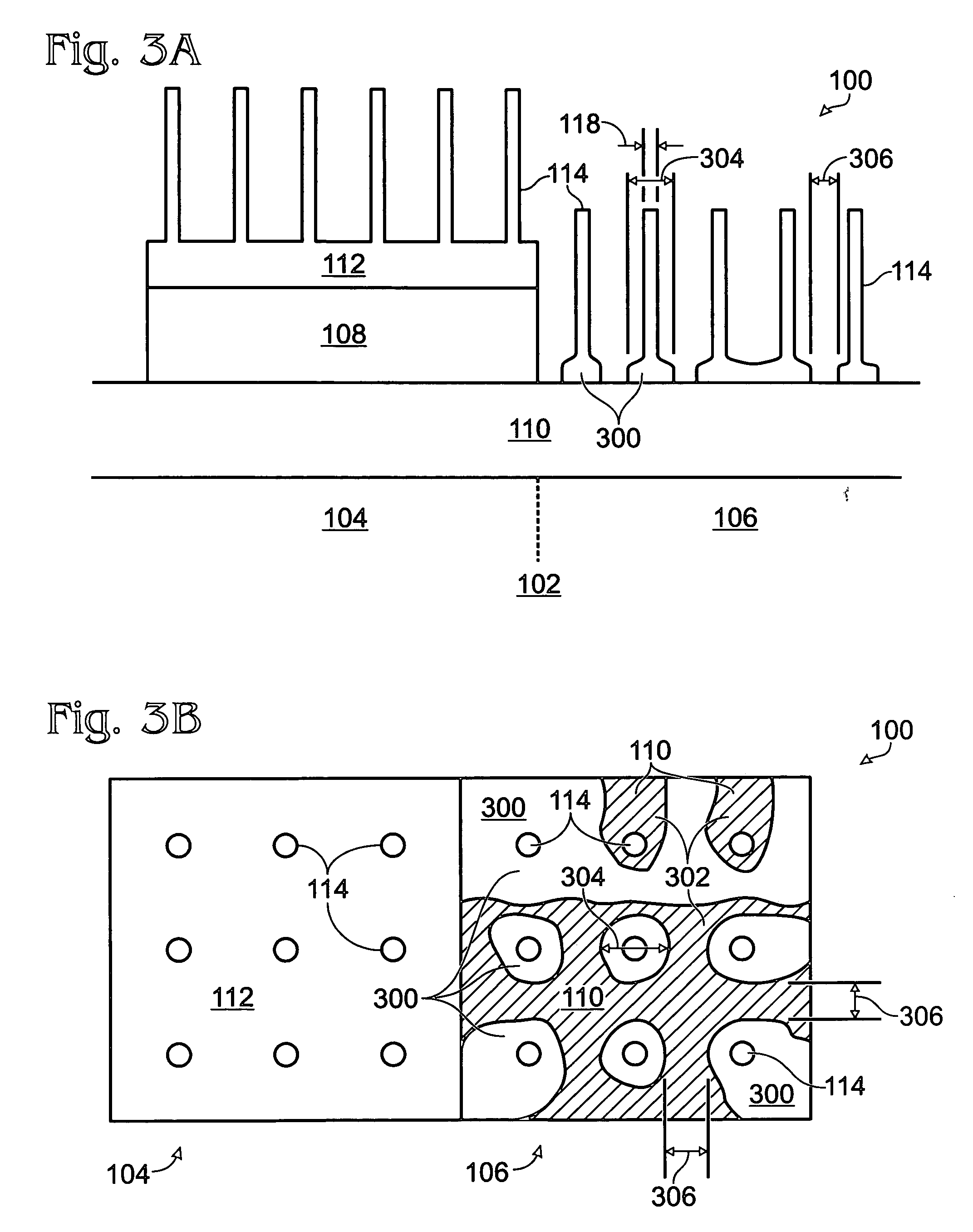

[0026]FIG. 1 is a partial cross-sectional view of a patterned iridium oxide (IrOx) nanostructure substrate. The patterned substrate 100 comprises a substrate 102 with a first region 104 and a second region 106 adjoining the first region 104. A first material 108 overlies a second material 110 in the first region 104. A continuous IrOx film 112 with grown IrOx nanostructures 114, having an aspect ratio in the range of 1:1 to 100:1, overlies the first material 108.

[0027] An “aspect ratio” is defined herein to be the length 116 of the nanostructures 114 with respect to the nanostructure diameter 118. IrOx is defined herein to be any iridium oxide compound, where “x” is any value between (and including) the values of zero and 2. In another aspect, the “x” value in the continuous IrOx film 112 is different than the “x” value in the nanostructures. For example, the continuous IrOx film 112 can be Ir (x=0), while the nanostructures 114 are IrOx, where x is greater than zero.

[0028] Typica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com