Plasma spray apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

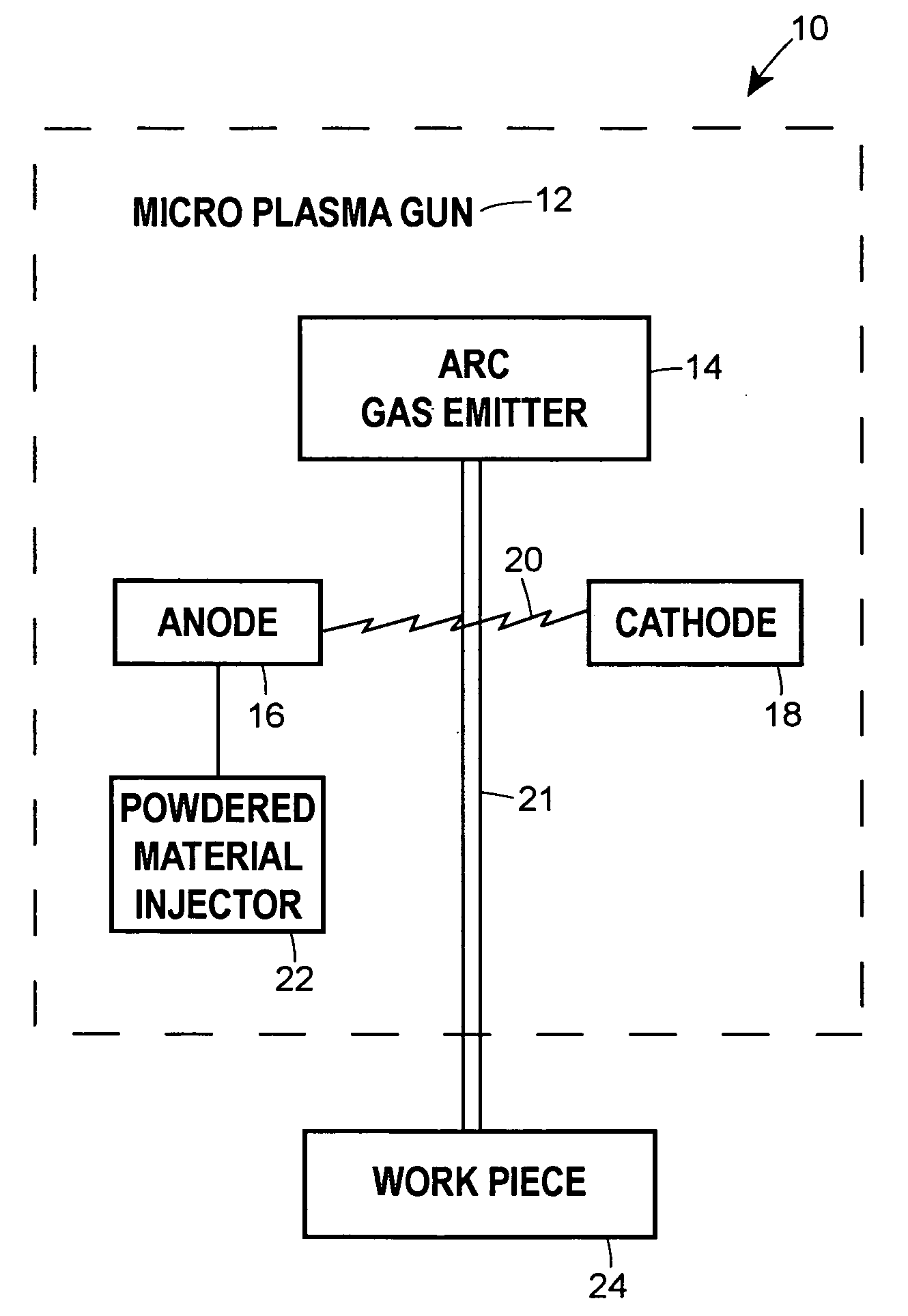

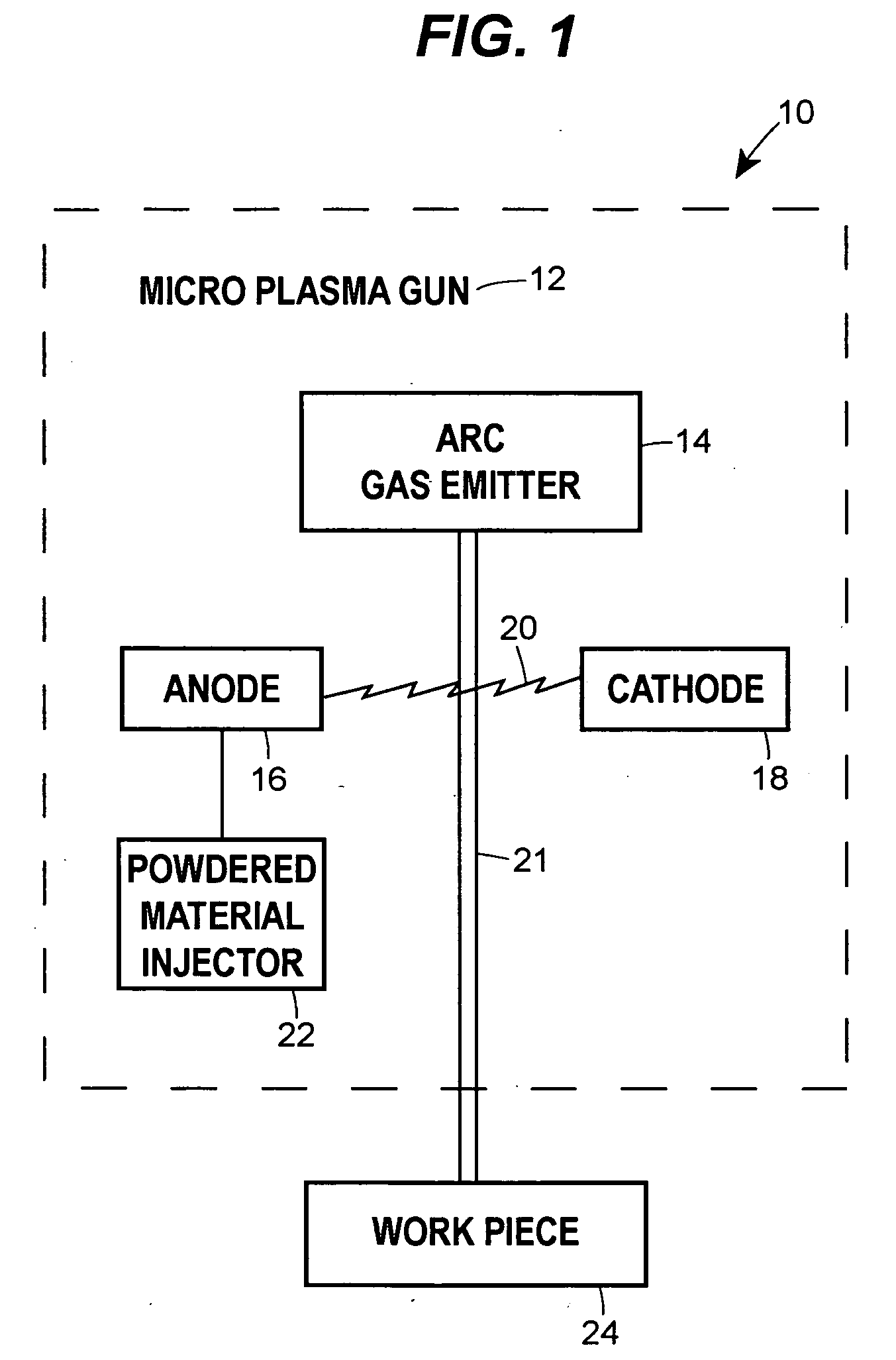

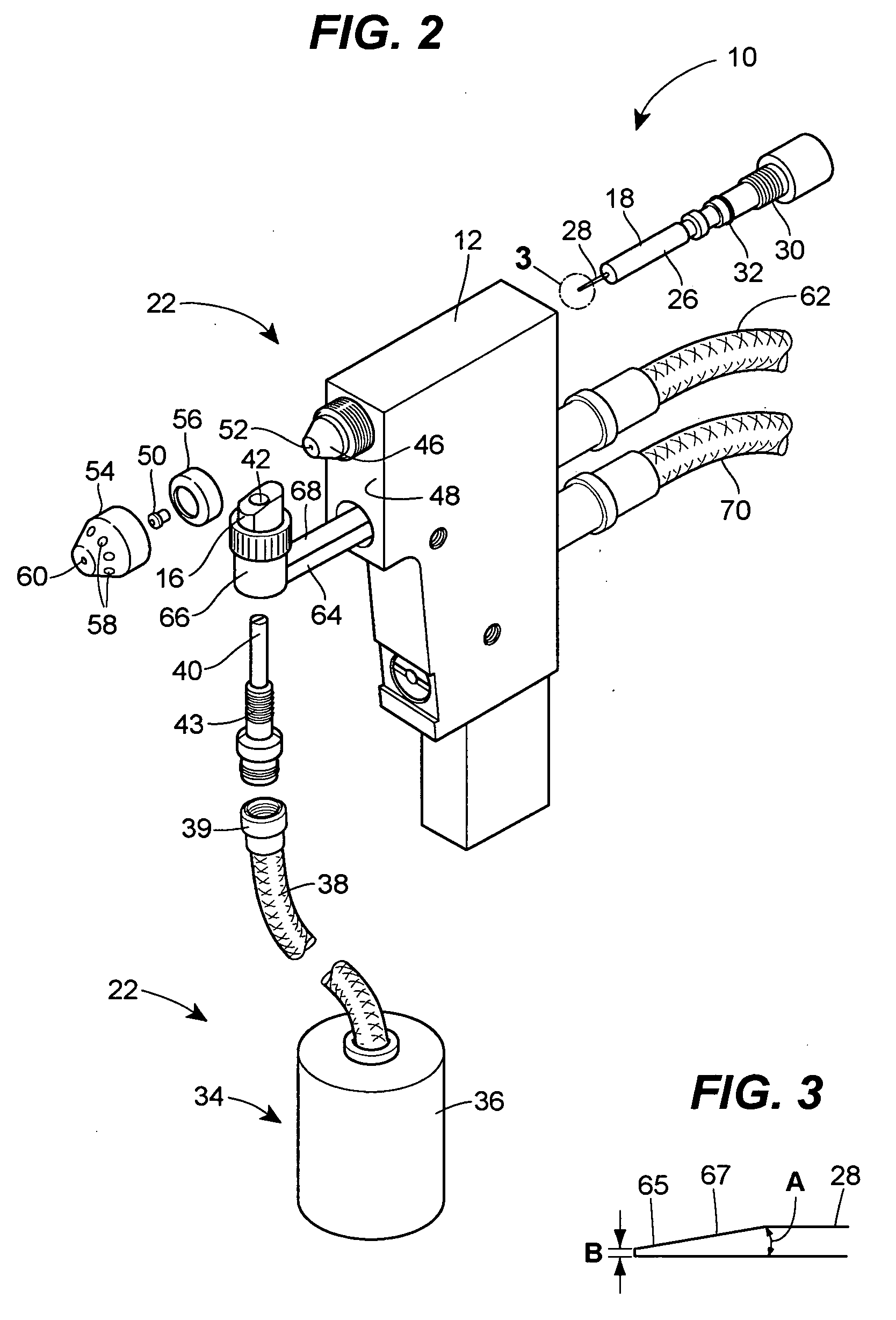

[0014] Referring now to FIG. 1, one embodiment of a plasma spray apparatus 10 schematically represented by the dashed box outline is depicted. In generalized terms, the plasma spray apparatus 10 includes a plasma gun 12 having an arc gas emitter 14, an anode 16, and a cathode 18. An electric arc 20 is generated between the anode 16 and cathode 18. A plasma stream 21 is formed when arc gas is injected from the arc gas emitter 14 and passes through the arc 20. A powdered material injector 22 dispenses powdered material into the plasma stream which transports the powdered material to the workpiece 24 to form a coating thereon. The size of the plasma stream 21 created by the device and / or the power used by the device determines whether the device is considered a microplasma spray apparatus. When the plasma stream 21 is small and / or the power used by the device is low, the device is considered a microplasma spray device. FIG. 1 displays a microplasma spray device.

[0015] For example, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com