Linear compressor

a compressor and linear technology, applied in the direction of machines/engines, positive displacement liquid engines, pumping pumps, etc., can solve the problem of difficult to reduce the size of the stator cover, and achieve the effect of reducing the number of elements of the linear compressor, reducing the size of the shell, and reducing the manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

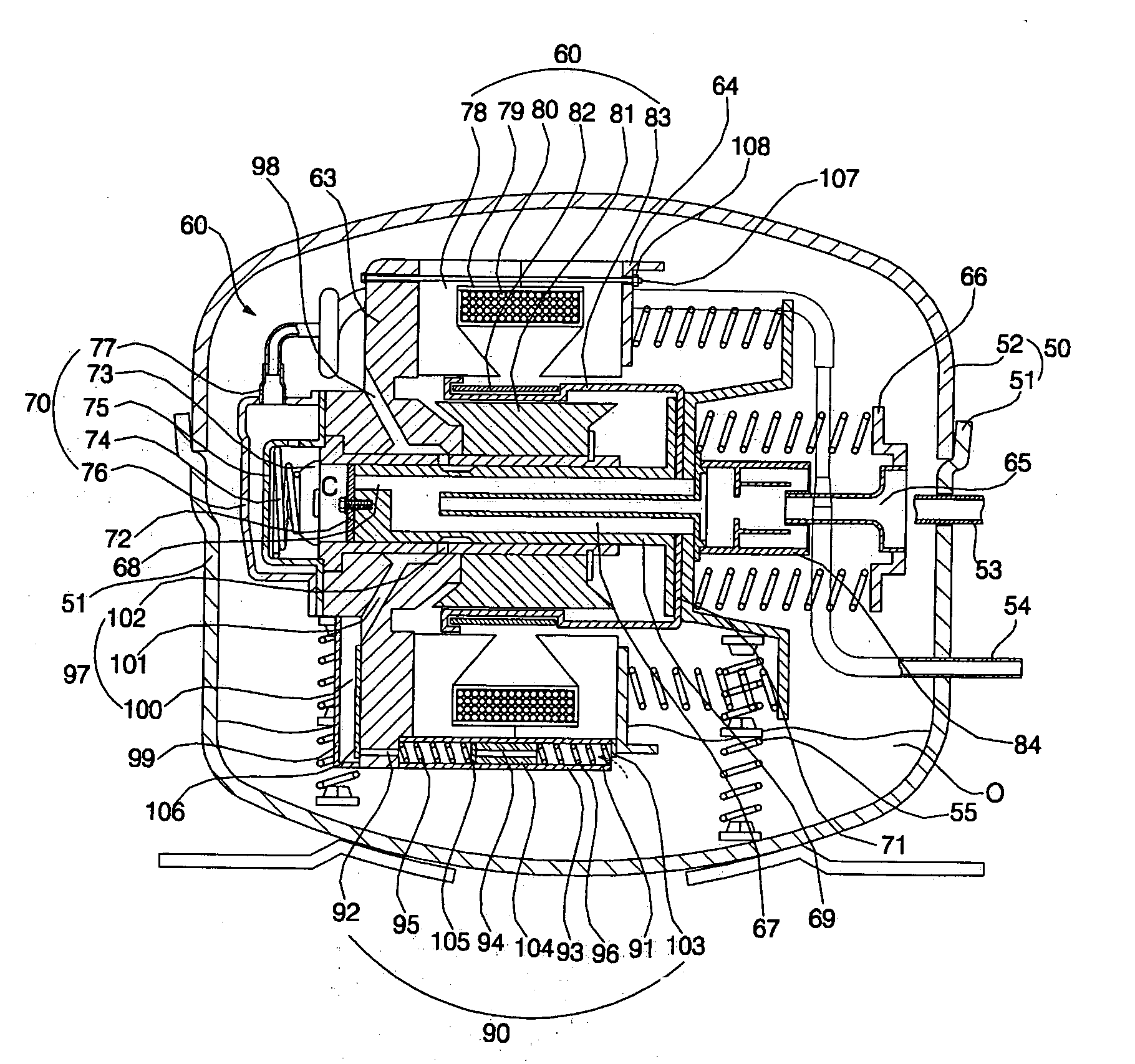

[0052]FIG. 3 is a front sectional view illustrating a linear compressor in accordance with the present invention.

[0053] As shown in FIG. 3, the linear compressor of the present invention comprises a linear compressing unit 60 mounted in a shell 50 in a shock-absorbing manner. The shell 50 is divided into a lower shell 51 having an open upper surface and an upper shell 52 configured to cover the upper surface of the lower shell 51. The lower and upper shells 51 and 52 are coupled to each other to define a hermetically sealed interior space therebetween. In a bottom region of the lower shell 51 is received oil O.

[0054] A fluid suction pipe 53 and a fluid discharge pipe 54 pass into the shell 50. The fluid discharge pipe 54 is also connected to the linear compressing unit 60 to discharge fluid, compressed in the linear compressing unit 60, to the outside. The linear compressing unit 60 is supported on dampers 55 mounted in the lower shell 51 so as to vibrate by means of the dampers 55...

second embodiment

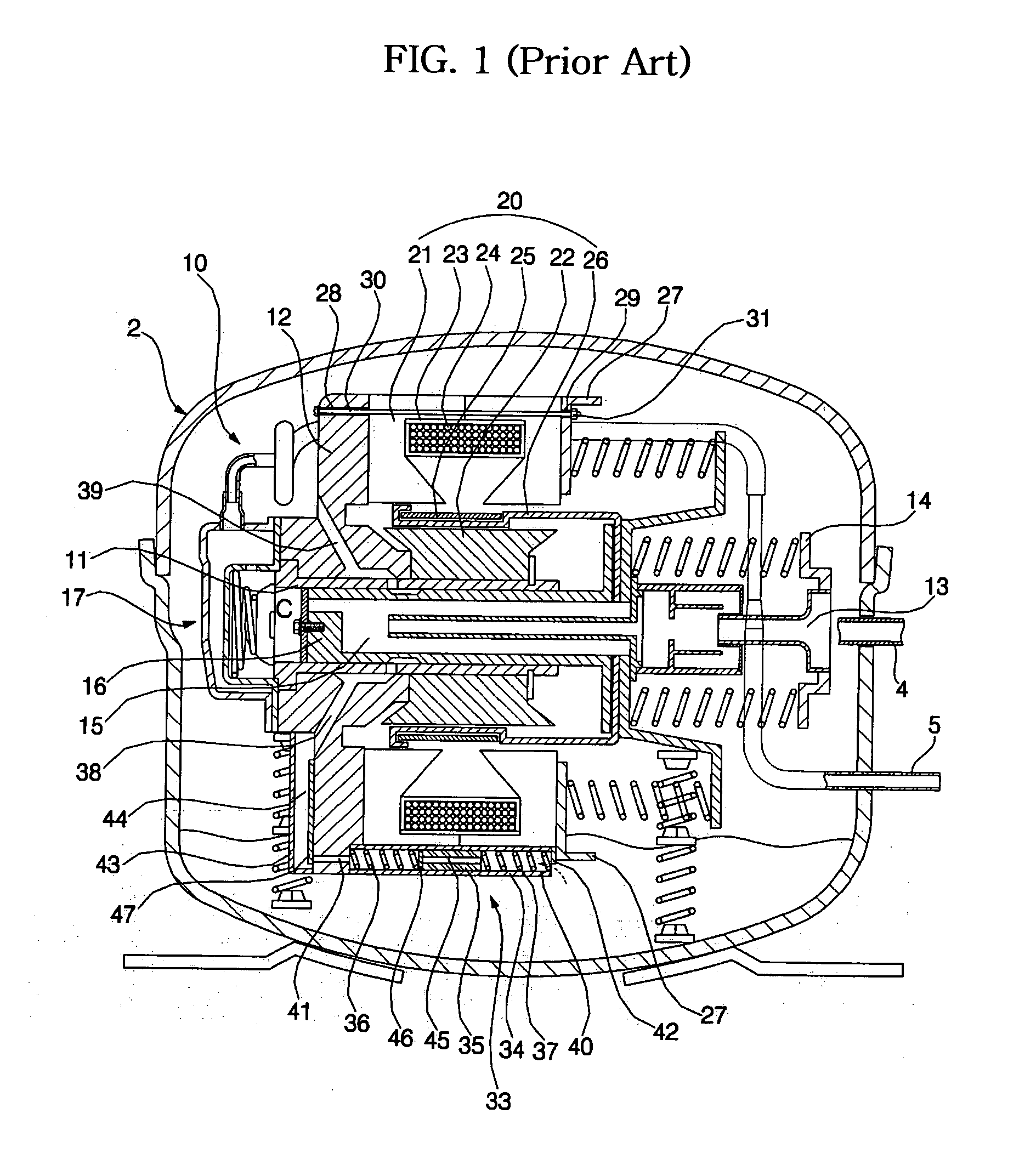

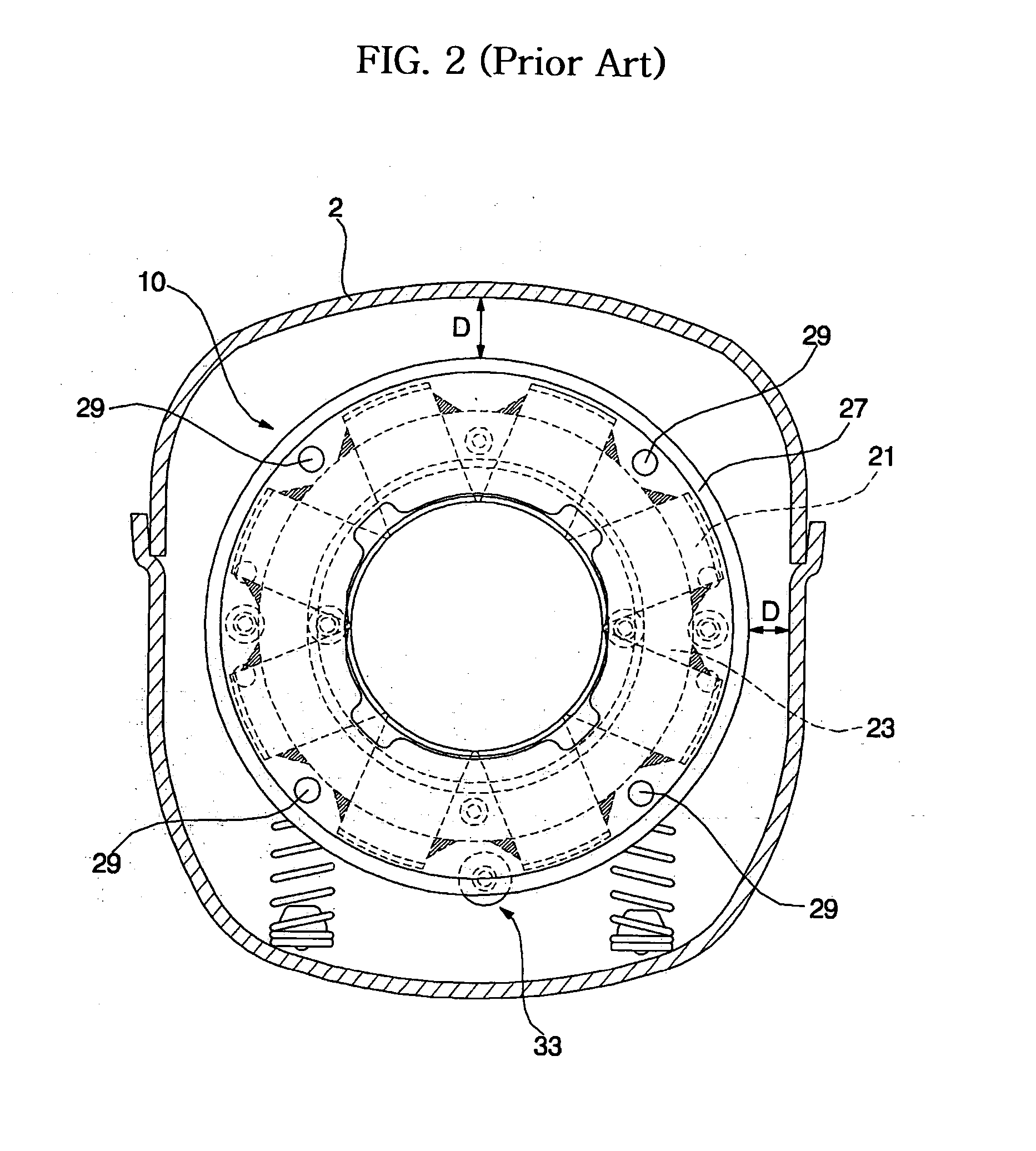

[0088]FIG. 6 is a front sectional view illustrating a linear compressor in accordance with the present invention.

[0089] As shown in FIG. 6, the linear compressor according to the present embodiment comprises: a shell 120 for receiving oil O; a linear motor 121 mounted in the shell 120; a cylinder frame 122 mounted in front of the linear motor 121; a stator cover 123 mounted in rear of the linear motor 121; a piston 125 rectilinearly reciprocably disposed in a cylinder 124 mounted in the cylinder frame 122; fastening device for fixing the cylinder frame 122 and the stator cover 123 to each other; and oil supply device for supplying the oil O received in the shell 120 into a gap between the cylinder 124 and the piston 125.

[0090] The linear motor 121 comprises: outer stators 126 interposed between the cylinder frame 122 and the stator cover 123; a bobbin 127 provided inside the outer stators 126; a coil 128 wound on the bobbin 127; an inner stator 129 mounted on the cylinder frame 122...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com