Flame simulating assembly

a technology of simulating assembly and flame, which is applied in the field of simulating assembly, can solve the problems of affecting the simulation effect, affecting the effect of simulation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

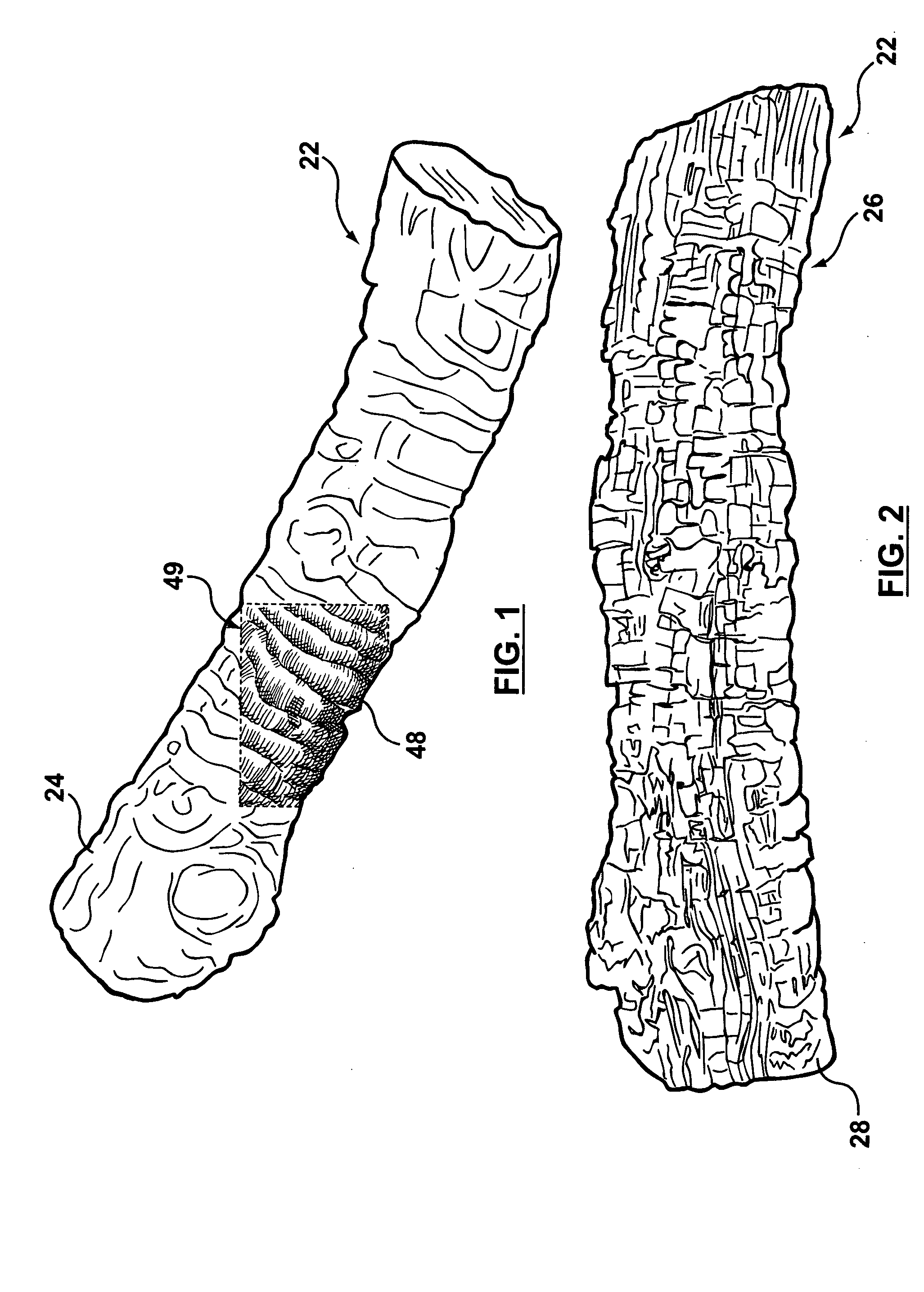

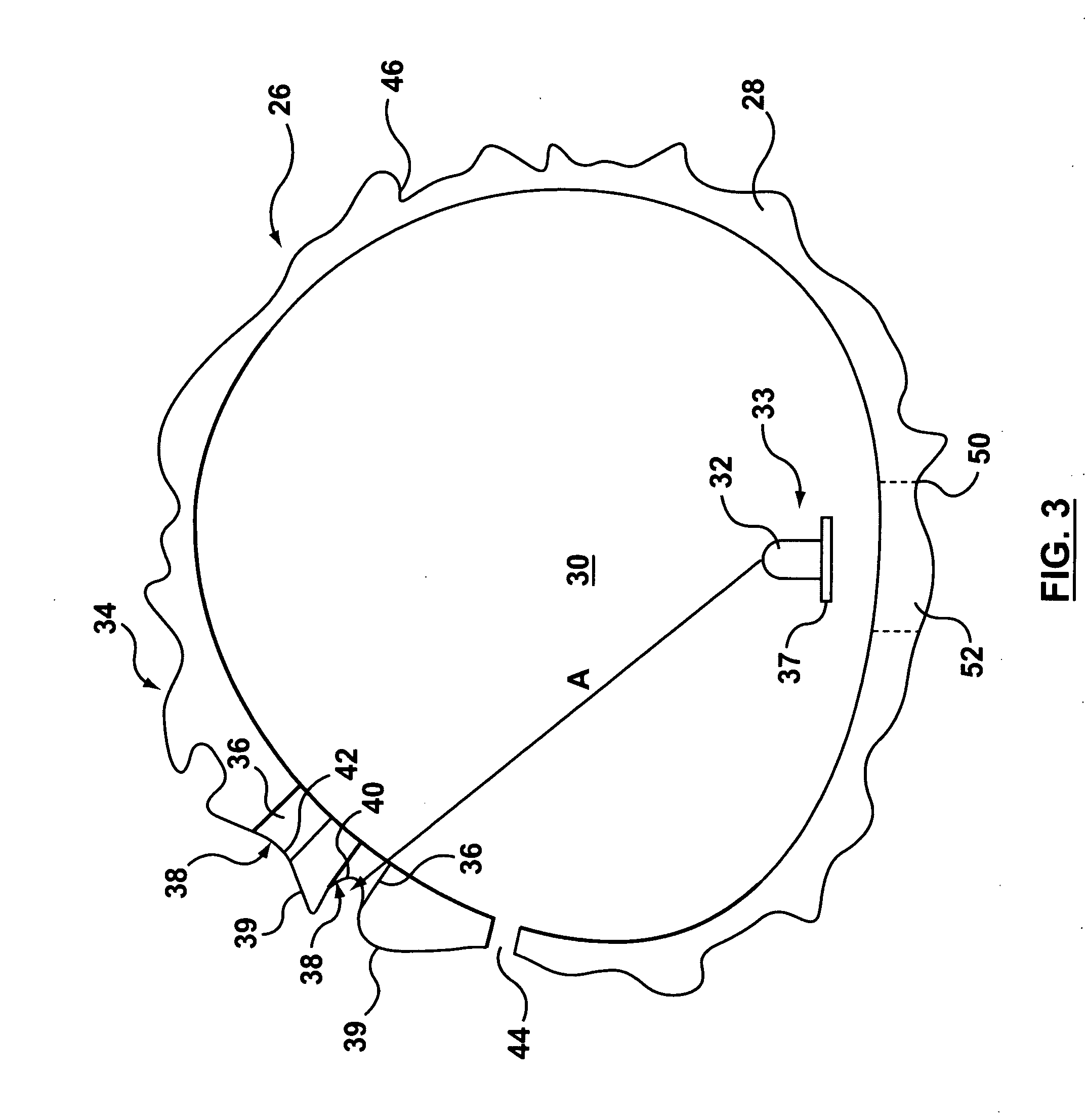

[0054] Reference is first made to FIGS. 1-7 to describe an embodiment of a simulated fuel bed in accordance with the invention indicated generally by the numeral 20 (FIGS. 4A, 4B). The simulated fuel bed 20 is for simulating a solid combustible fuel burning, and partially consumed, in a natural fire. Preferably, the simulated fuel bed 20 includes a number of simulated solid combustible fuel elements 22 (FIGS. 7, 8), for simulating fuel elements which have not been consumed by the fire, or have only partially been consumed. Each simulated combustible fuel element 22 has a body 24 which is colored and formed to resemble an entire solid combustible fuel element, as will be described.

[0055] As shown in FIGS. 4A, 4B and 5, the elements 22 are preferably arranged in a pile 25, for instance, to imitate a pile of wooden logs in a natural fire. It will be understood that the simulated fuel elements 22 may, in the alternative, be formed and colored to resemble pieces of coal. Where the simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com