Autoignition material and method

a technology of autoignition and materials, applied in the direction of ignitors, weapons, explosives, etc., can solve the problem that prior art generally fails to provide an autoignition material, and achieve the effect of reducing or preventing age-induced weight loss and enhancing aging characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

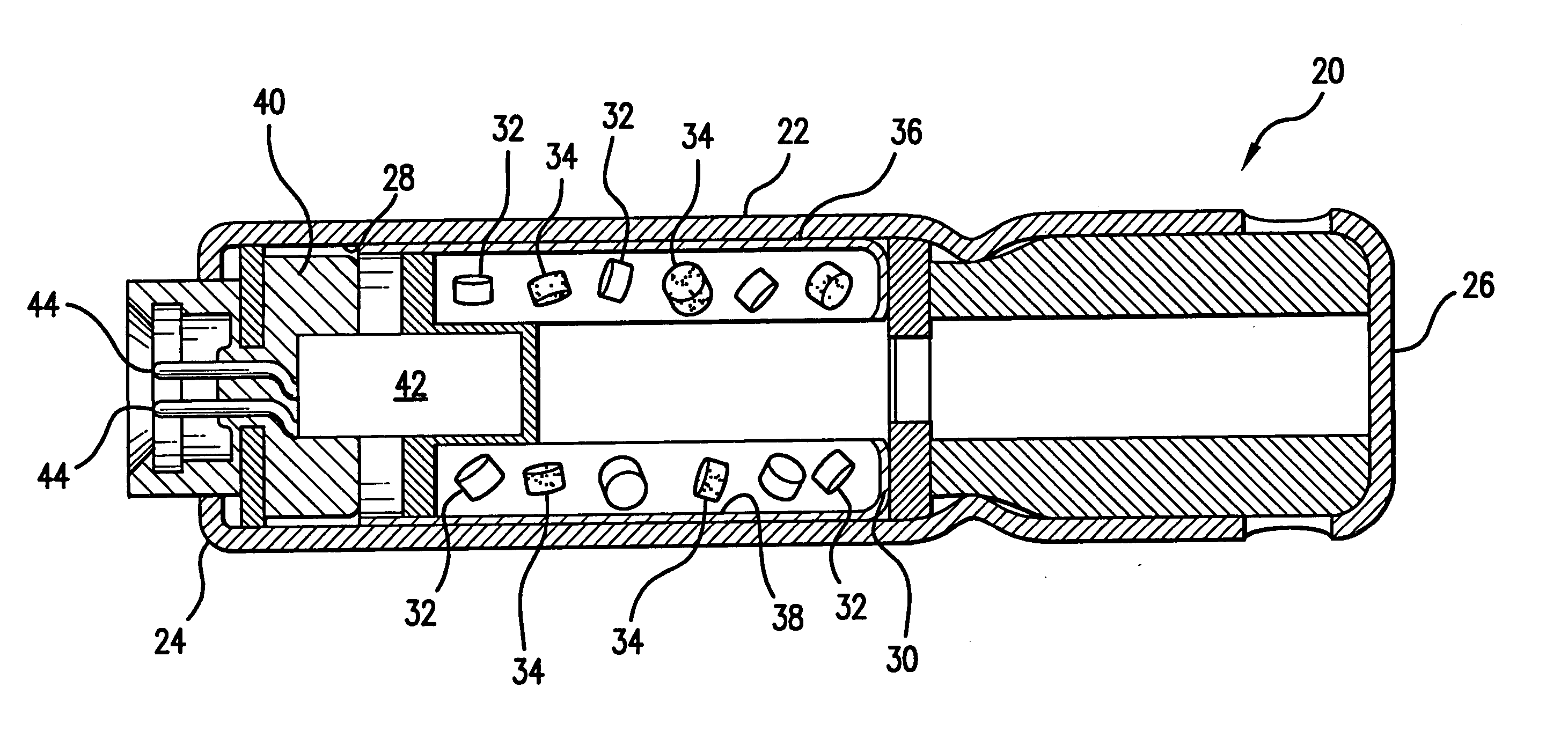

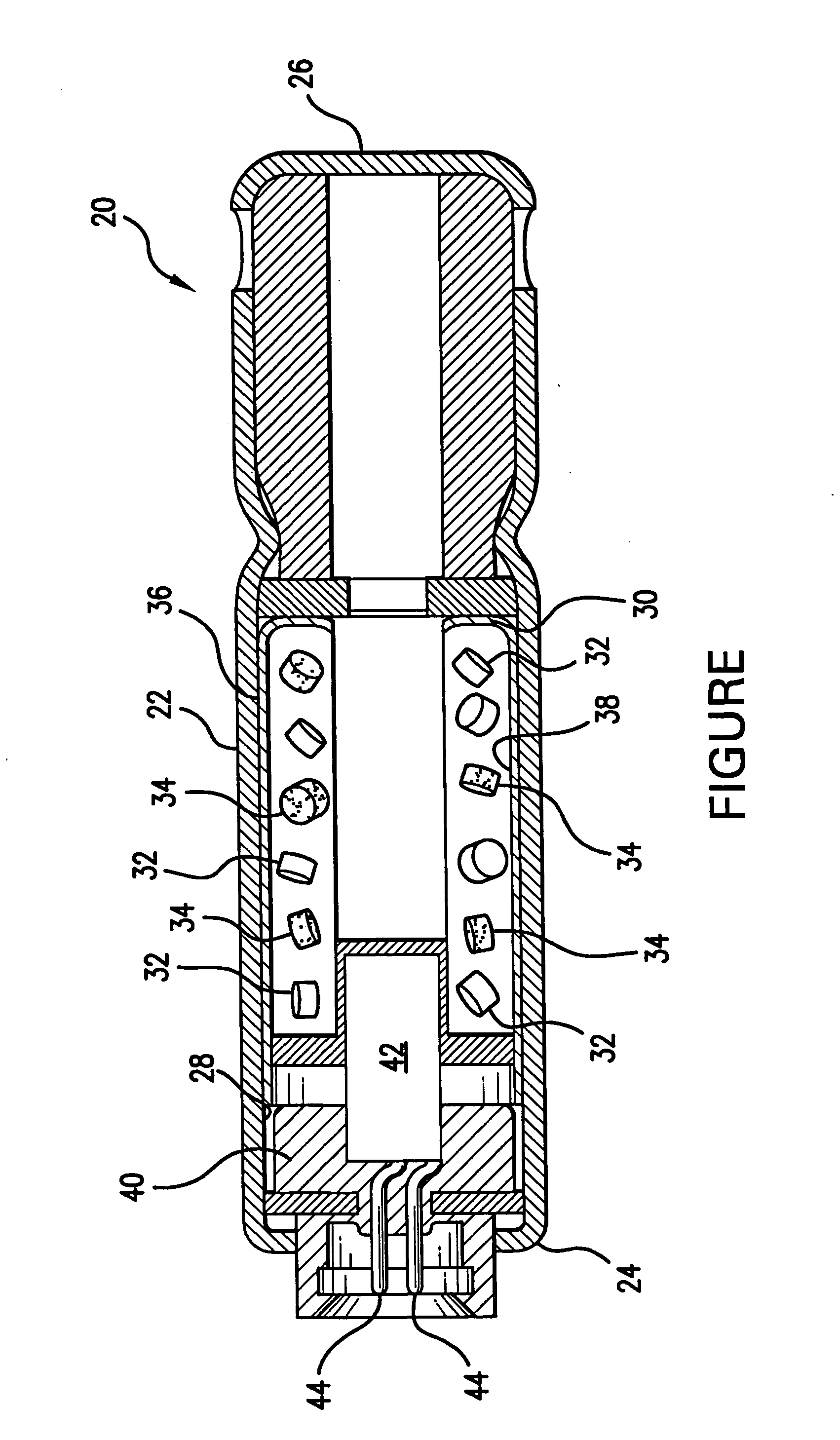

Image

Examples

examples

[0034] Autoignition materials were prepared having the compositions identified in TABLE 1 below. The autoignition materials in accordance with Comparative Example 1 (CE1) and Comparative Example 2 (CE2) each had an equivalence ratio (ER) of about 1.0 while the autoignition material of Example 1 (EX1), in accordance with the invention, was over-fueled, i.e., had an equivalence ratio of less than 0.8.

TABLE 1CE1CE2EX1Ethyl Cellulose2.004.002.00ADCA28.3423.2140.00BCN64.6667.7953.00Chabazite5.005.005.00ER1.001.000.78ADCA / BCN ratio0.440.340.75

ADCA = Azodicarbonamide

Test Methods and Data:

[0035] Samples of each of the autoignition materials were tested to determine the Autoignition Temperature (AIT), measured at heating rate of 10° C. / minute, before aging, after aging at 107° C. for 400 hours and after aging at 90° C. for 1000 hours. The autoignition temperatures were measured by placing samples of each material to be tested in a test tube held in an aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| autoignition temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com