Method of recording information on an optical information recording medium

a technology of optical information and recording medium, which is applied in the field of optical information recording medium, can solve the problems of insufficient storage stability, insufficient recording characteristics, and insufficient reflectance and percentage modulation, and achieve excellent recording characteristics and high versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

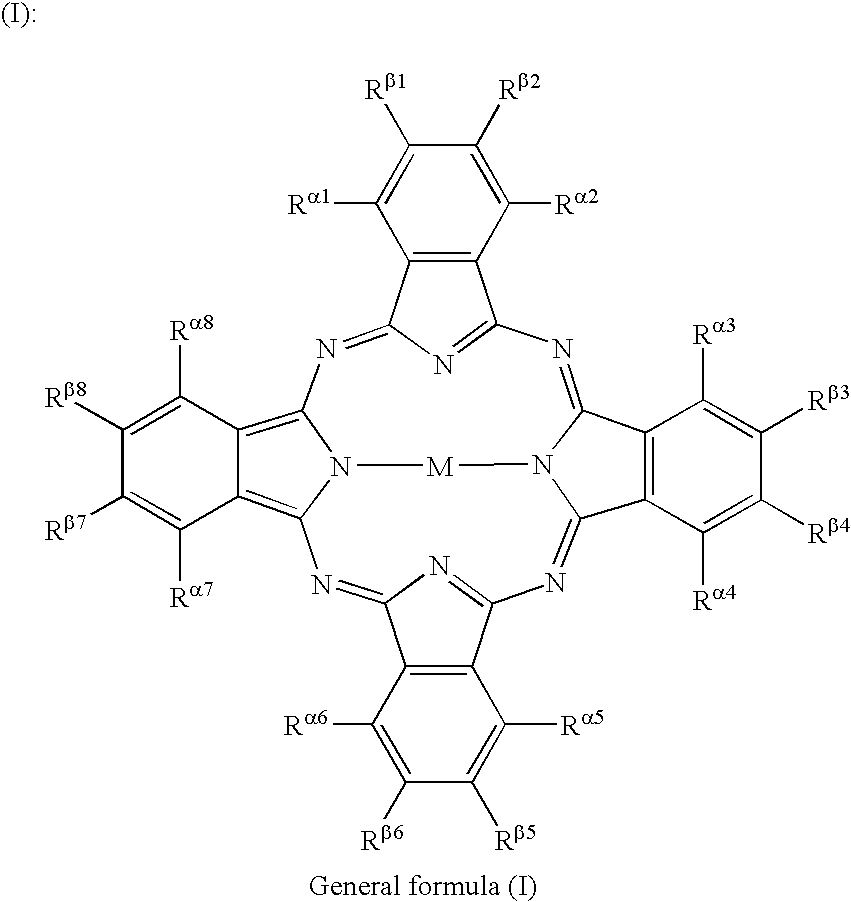

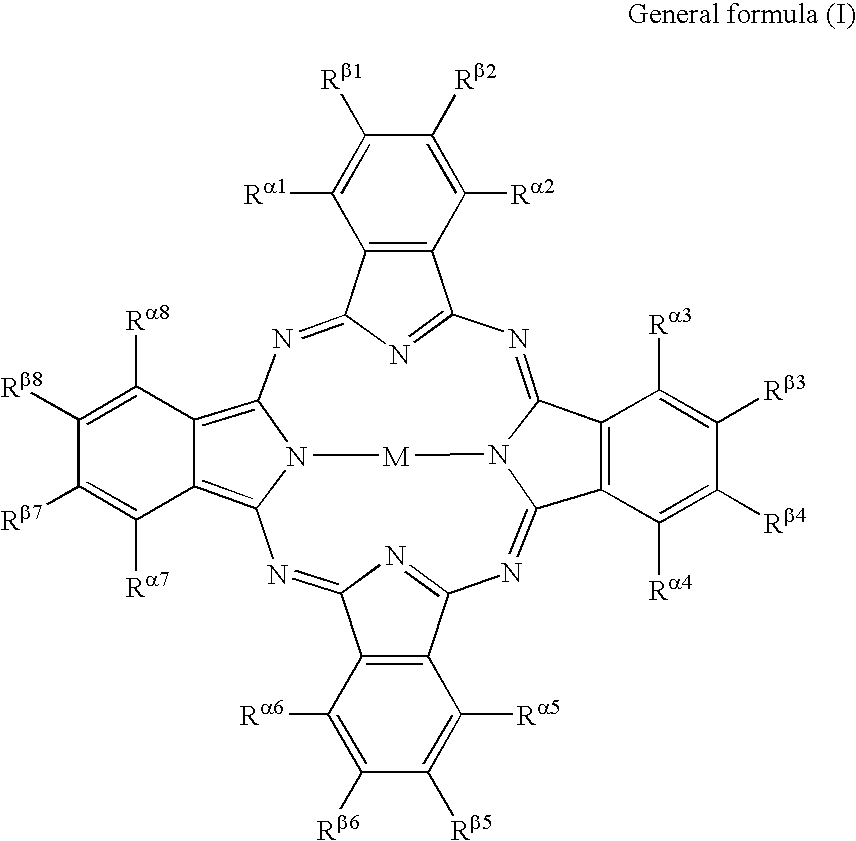

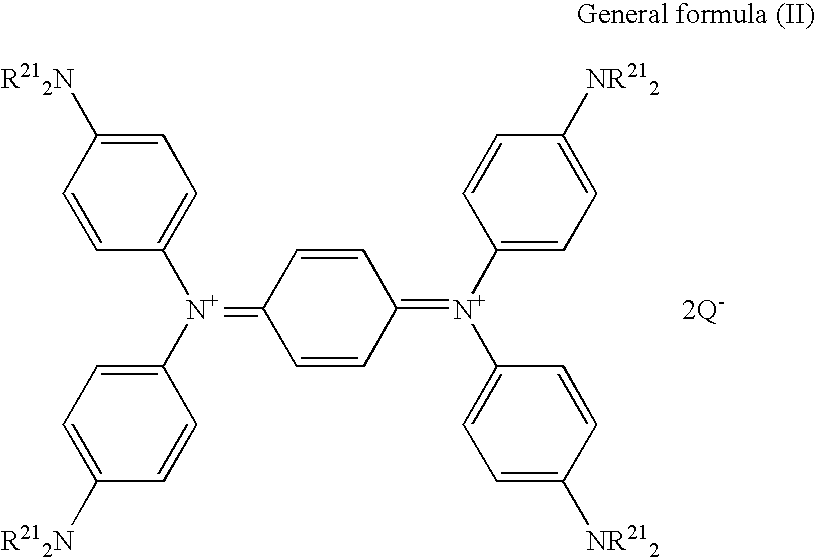

Image

Examples

example 1

[0067] A compound (I-1) was dissolved into 2,2,3,3-tetrafluoropropanol to obtain a coating solution for forming a recording layer (concentration: 1% by weight). The coating solution was spin-coated onto the surface of a polycarbonate substrate (diameter: 120 nm; thickness: 0.6 mm) disposed with a spiral pre-groove (track pitch: 0.4 μm; groove width: 0.2 μm; groove depth: 0.08 μm) formed by injection molding, whereby the recording layer was formed (thickness (inside pre-groove): approximately 80 nm).

[0068] Next, silver was sputtered onto the recording layer to form a reflective layer having a thickness of approximately 100 nm. A UV-curable resin (SD 318 made by Dainippon Ink and Chemical Co., Ltd.) was then coated onto the reflective layer and cured by being irradiated with ultraviolet light, whereby a protective layer having a thickness of 7 μm was formed. Thus, an optical disc of the present invention was obtained.

examples 2 to 17

[0069] Optical discs of the invention were formed in the same manner as in Example 1, except that compound (1-1) was changed to compounds shown in Table 6 (amount not changed).

example 18

[0074] A compound (I-3) was dissolved into dibutyl ether to obtain a coating solution for forming a recording layer (concentration: 1% by weight). The coating solution was spin-coated onto the surface a polycarbonate substrate (diameter: 120 nm; thickness: 0.6 mm) disposed with a spiral pre-groove (track pitch: 1.0 μm; groove width: 0.4 μm; groove depth: 0.15 μm) formed by injection molding, whereby the recording layer was formed (thickness (inside pre-groove): approximately 170 nm).

[0075] Next, silver was sputtered onto the recording layer to form a reflective layer having a thickness of approximately 100 nm. A UV-curable resin (SD 318 made by Dainippon Ink and Chemical Co., Ltd.) was then coated onto the reflective layer and cured by being irradiated with ultraviolet light, whereby a protective layer having a thickness of 7 μm was formed. Thus, an optical disc of the present invention was obtained.

Evaluation 2 as an Optical Disc

[0076] A 14T-EFM signal was recorded on the optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com