Method and apparatus for local polishing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

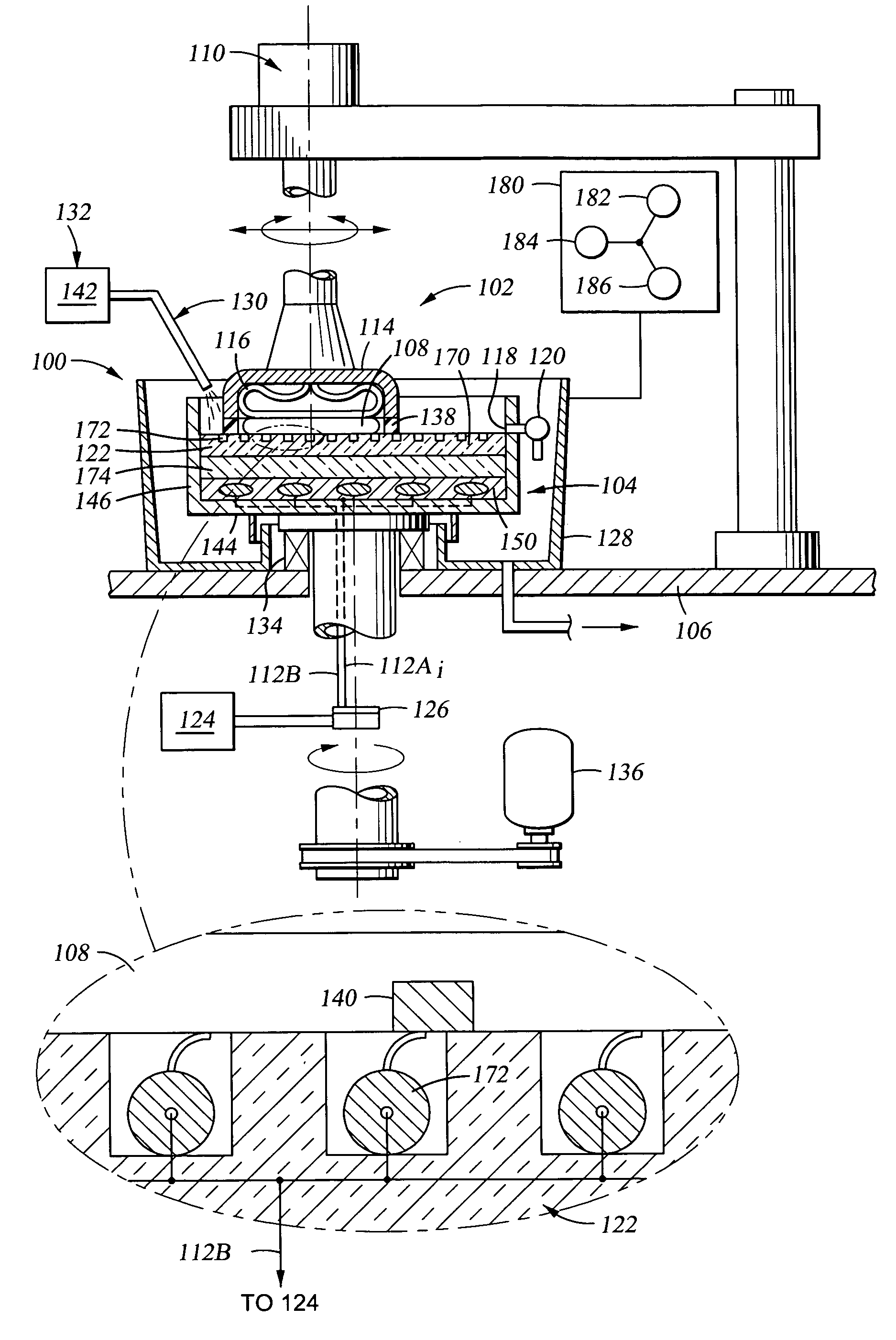

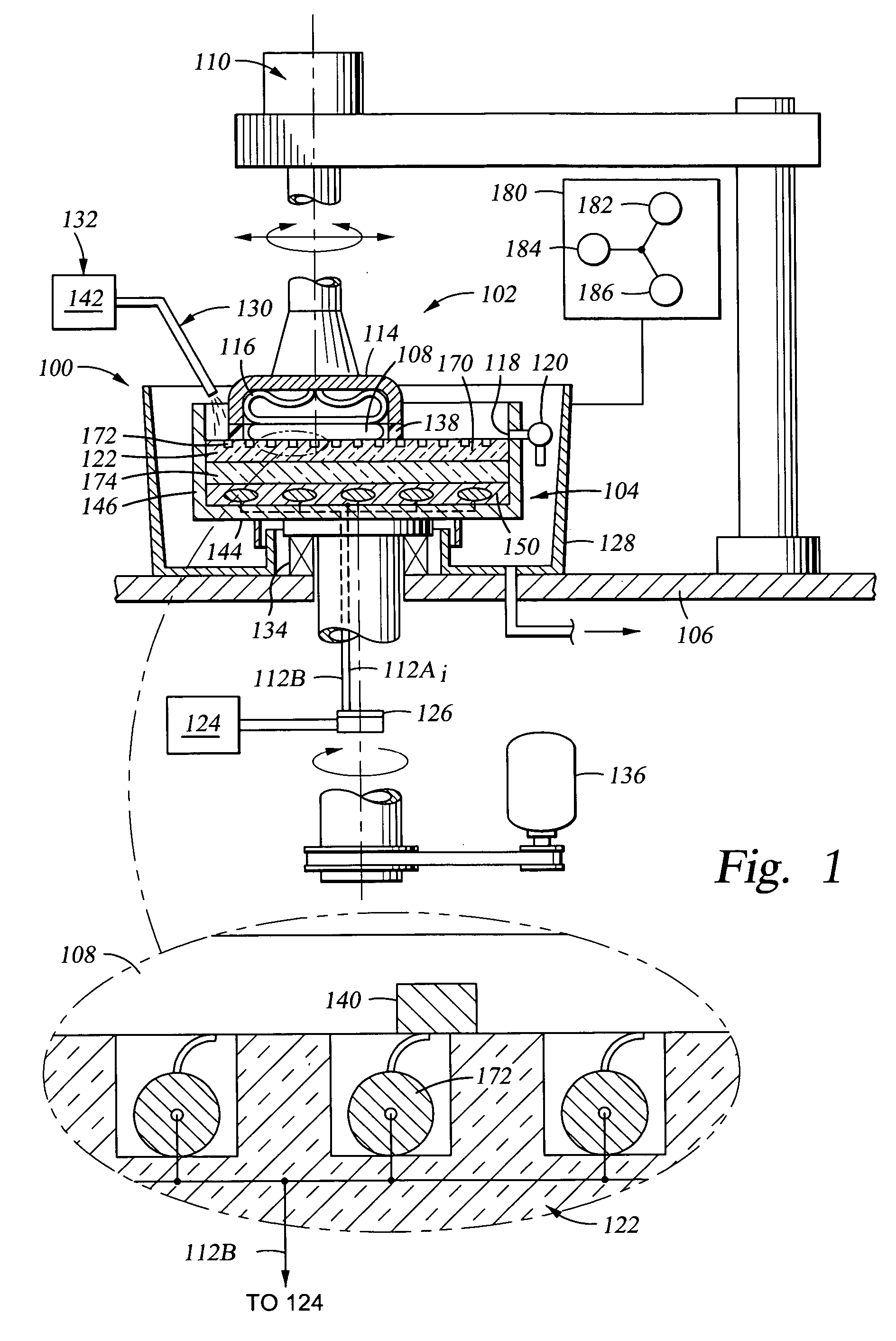

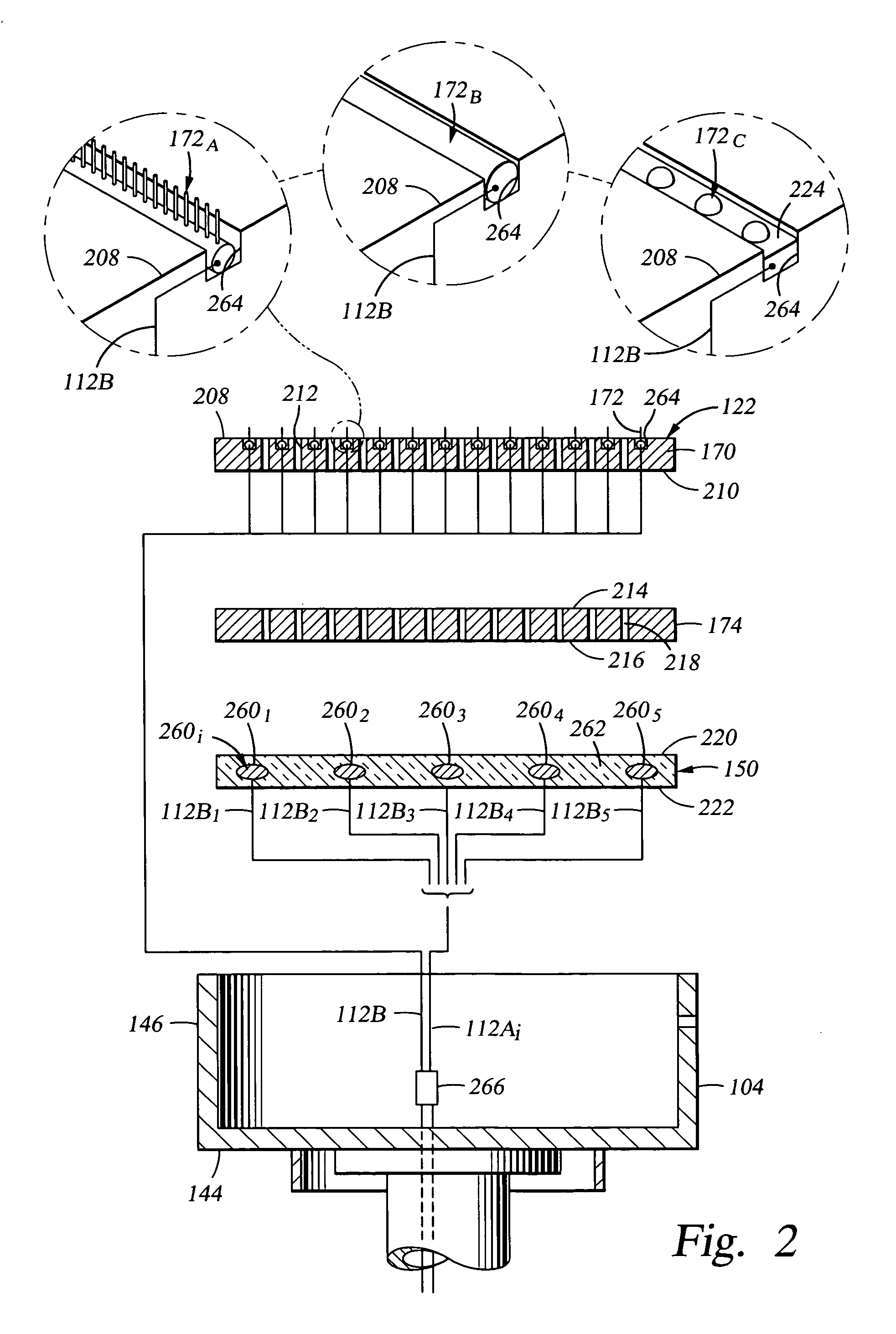

Image

Examples

Embodiment Construction

[0040] The words and phrases used herein should be given their ordinary and customary meaning in the art by one skilled in the art unless otherwise further defined herein. Chemical-mechanical polishing should be broadly construed and includes, but is not limited to, abrading a substrate surface by chemical activity, mechanical activity, or a combination of both chemical and mechanical activity. Electropolishing should be broadly construed and includes, but is not limited to, planarizing a substrate by the application of electrochemical activity. Electrochemical mechanical polishing (ECMP) should be broadly construed and includes, but is not limited to, planarizing a substrate by the application of electrochemical / chemical activity, or a combination of both electrochemical / chemical and mechanical activity to remove material from a substrate surface. Electrochemical mechanical plating process (ECMPP) should be broadly construed and includes, but is not limited to, electrochemically de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap