Depositing heat-treated aluminum using ultrasonic consolidation

a technology of ultrasonic consolidation and heat-treated aluminum, which is applied in the field of ultrasonic object consolidation, can solve the problems of constant variation in the amount of power required to achieve this, and achieve the effect of reducing the amount of slumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

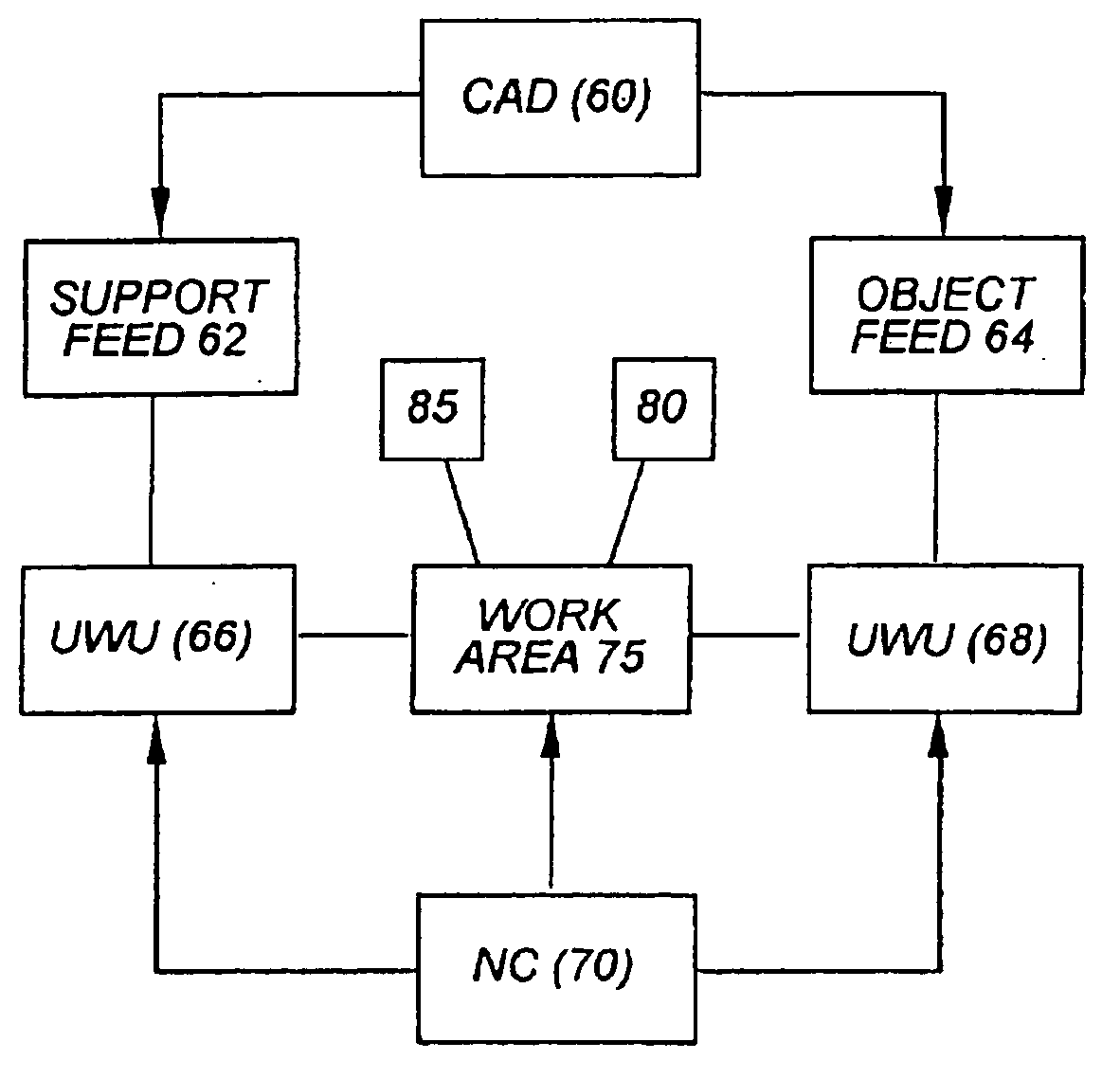

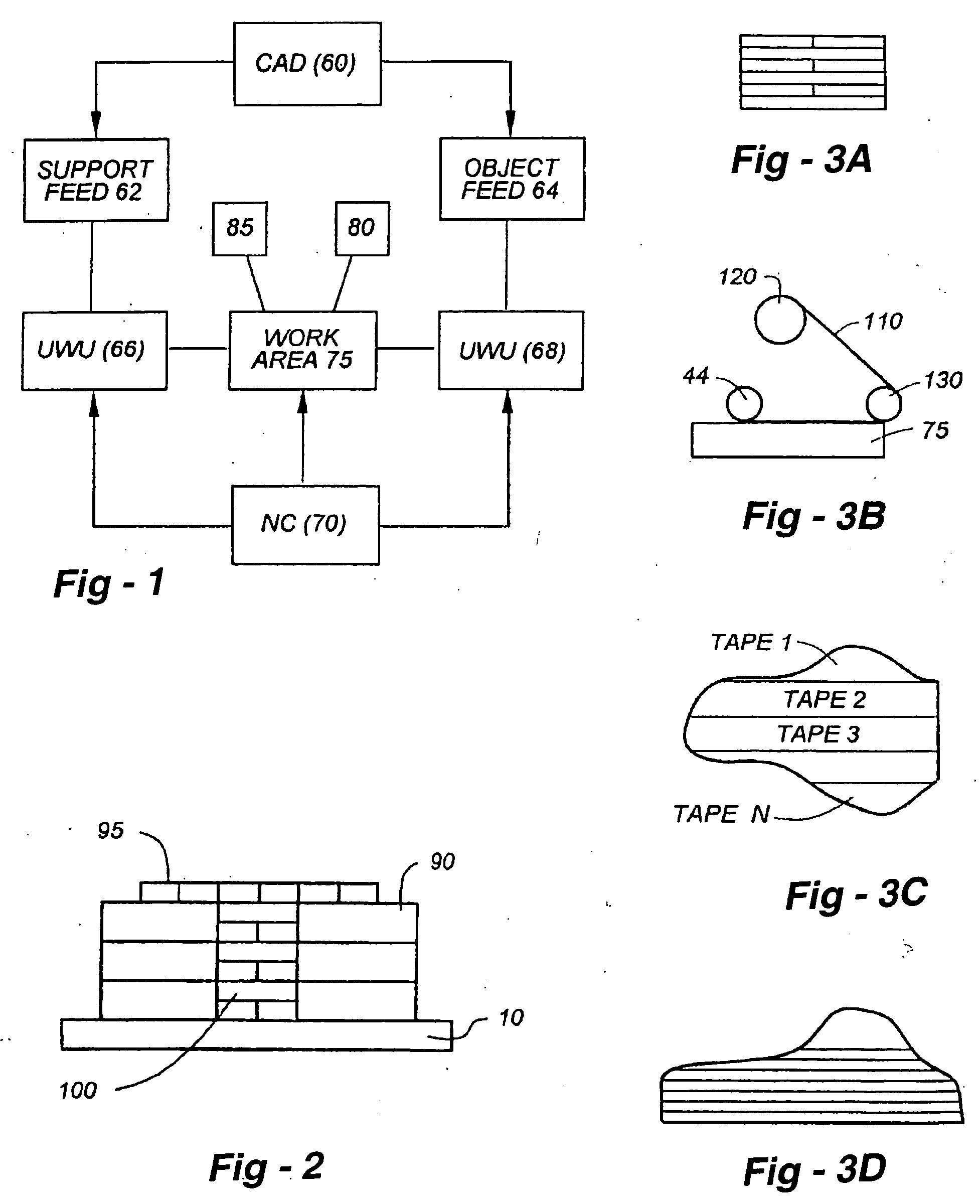

[0020]FIG. 1 is a schematic diagram of an automated ultrasonic consolidation system to which the invention is applicable. A computer-aided design unit 60 provides a layer-by-layer description of the object and of the support, as needed. The object material is fed onto the work area 75 by an object-material feed unit 64. The support material is fed onto the work area 75 by a support-material feed unit 62. The feed units may be combined into one when the shapes of the object and support layers are compatible, for instance sheets of plastic are used for the support and sheets of aluminum foil for the object. In general, two different feed units are required.

[0021] As shown in FIG. 2, the object may be fabricated by consolidating segments of tape 100 or filament or dots of material, as described below in other embodiments of the invention, while the support for overhanging parts 95 of the object may be constructed by adding layers of support material 90.

[0022] The object layers may be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Creep rate | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com