Fluid processing device for oligonucleotide synthesis and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

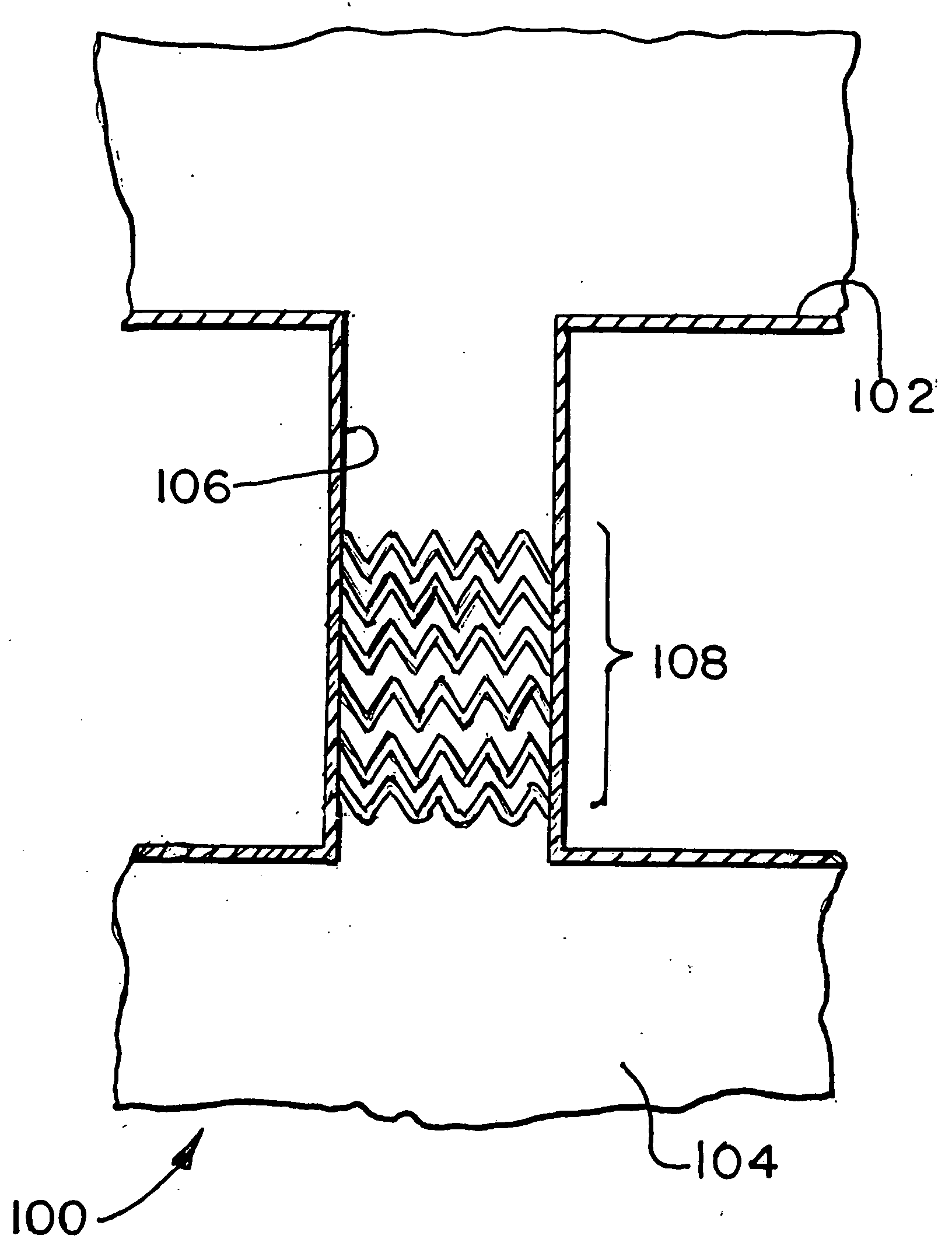

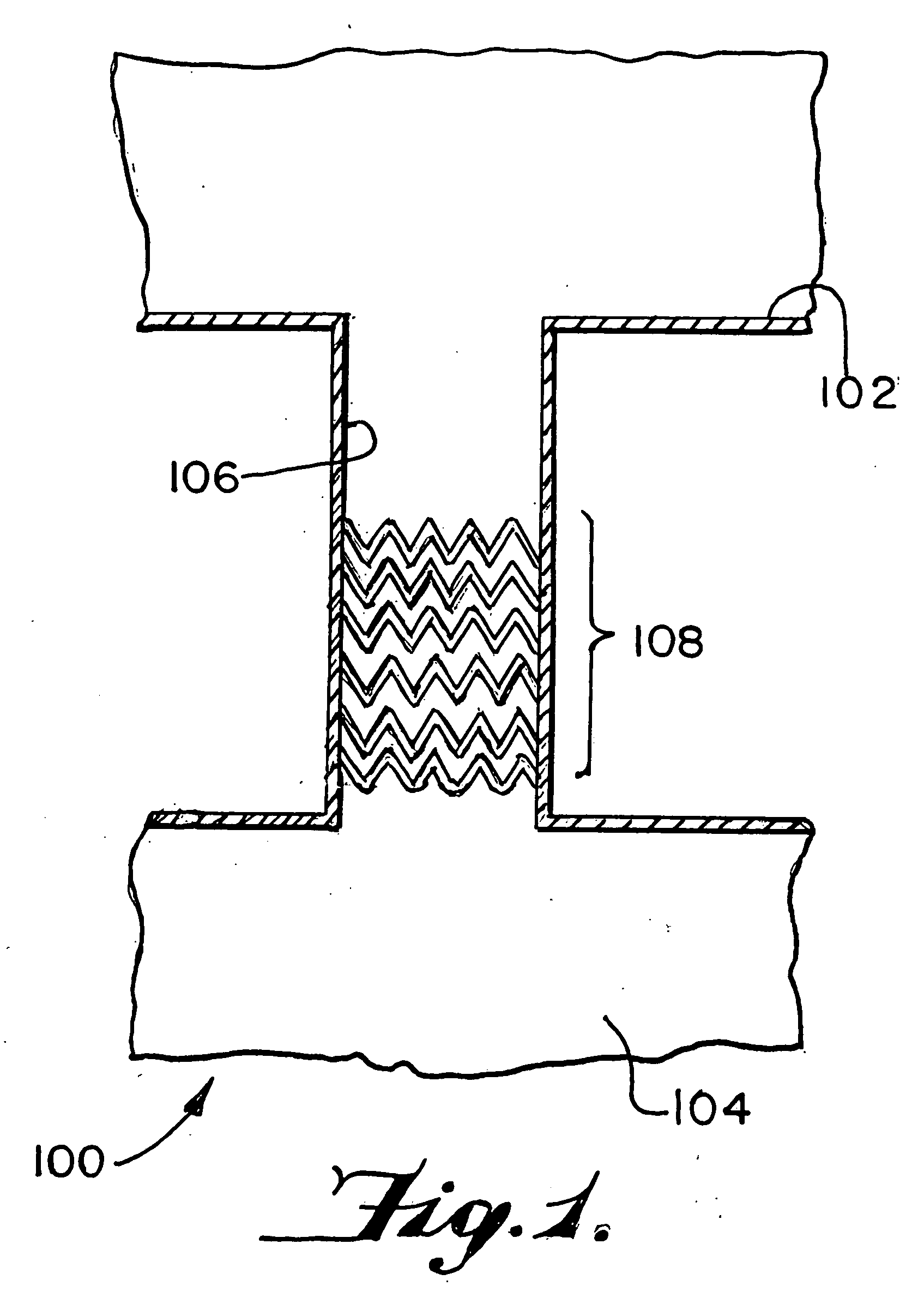

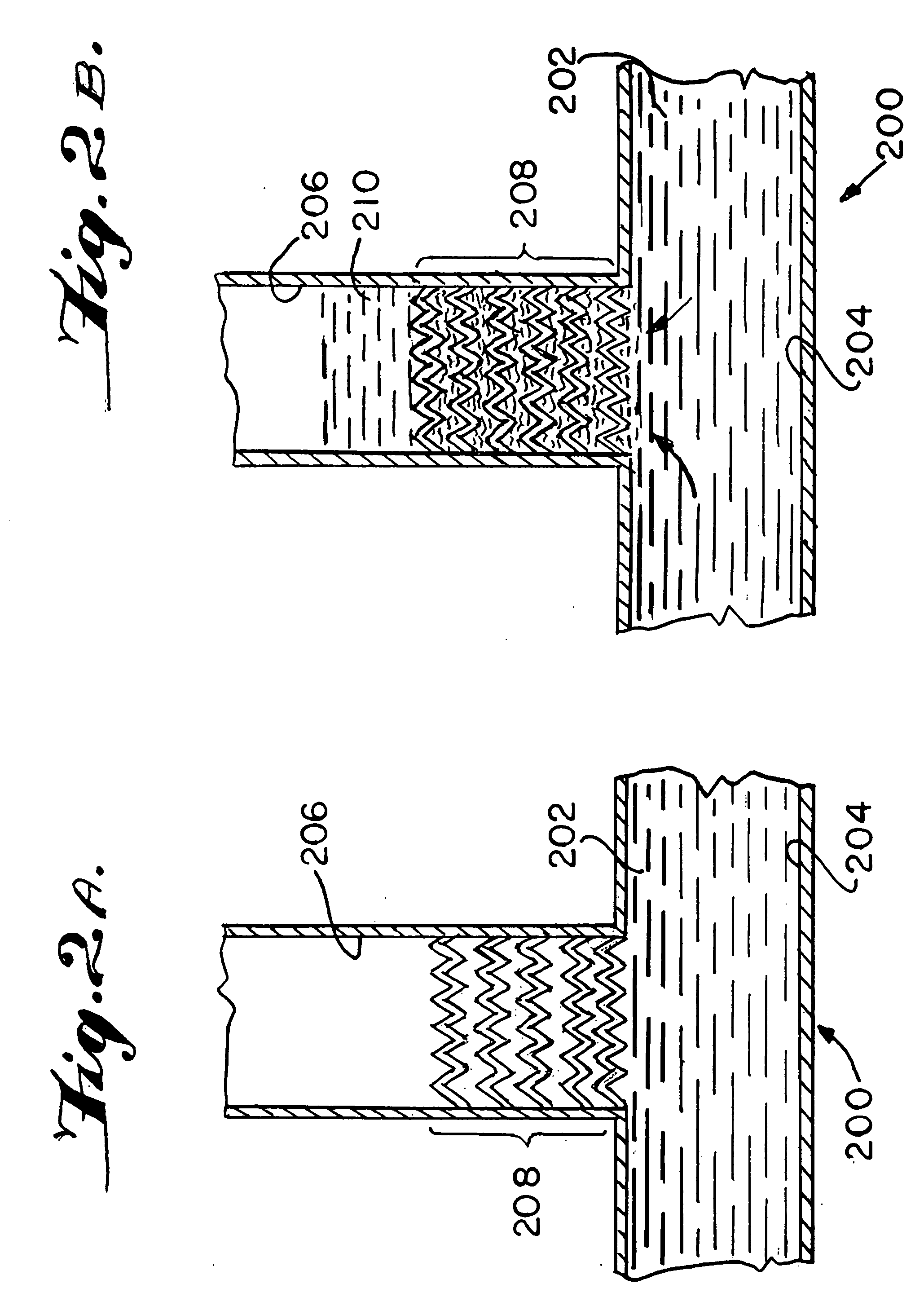

[0025] According to various embodiments, a fluid processing device is provided that can be used to manipulate the delivery of reactants or reaction components to a reaction site to enable the production of one or more compounds comprising multiple building blocks, for example, one or more desired oligomers or one or more desired oligonucleotides. Oligomers as defined herein can include polymers of amino acids, polymers of sugars, polymers of nucleotide bases, polymers of nucleotide analogs, and / or polymers of other nucleotide monomeric units herein referred to as nucleotides.

[0026] According to various embodiments, the device described herein can be useful in carrying out chemical compound synthesis methods using building blocks, exemplified herein with oligonucleotide synthesis methods. These methods can comprise, for example, various oligonucleotide extension reactions, protecting and / or deprotecting reactions, capping reactions, washing steps, cleaving reactions, and the like. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com