Piston pump

a technology of piston pump and suction valve, which is applied in the direction of piston pump, positive displacement liquid engine, machine/engine, etc., can solve the problems of negative impact of the net positive suction head npsh, and achieve the effect of low pulsation, positive control of suction and pressure valve, and efficient function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

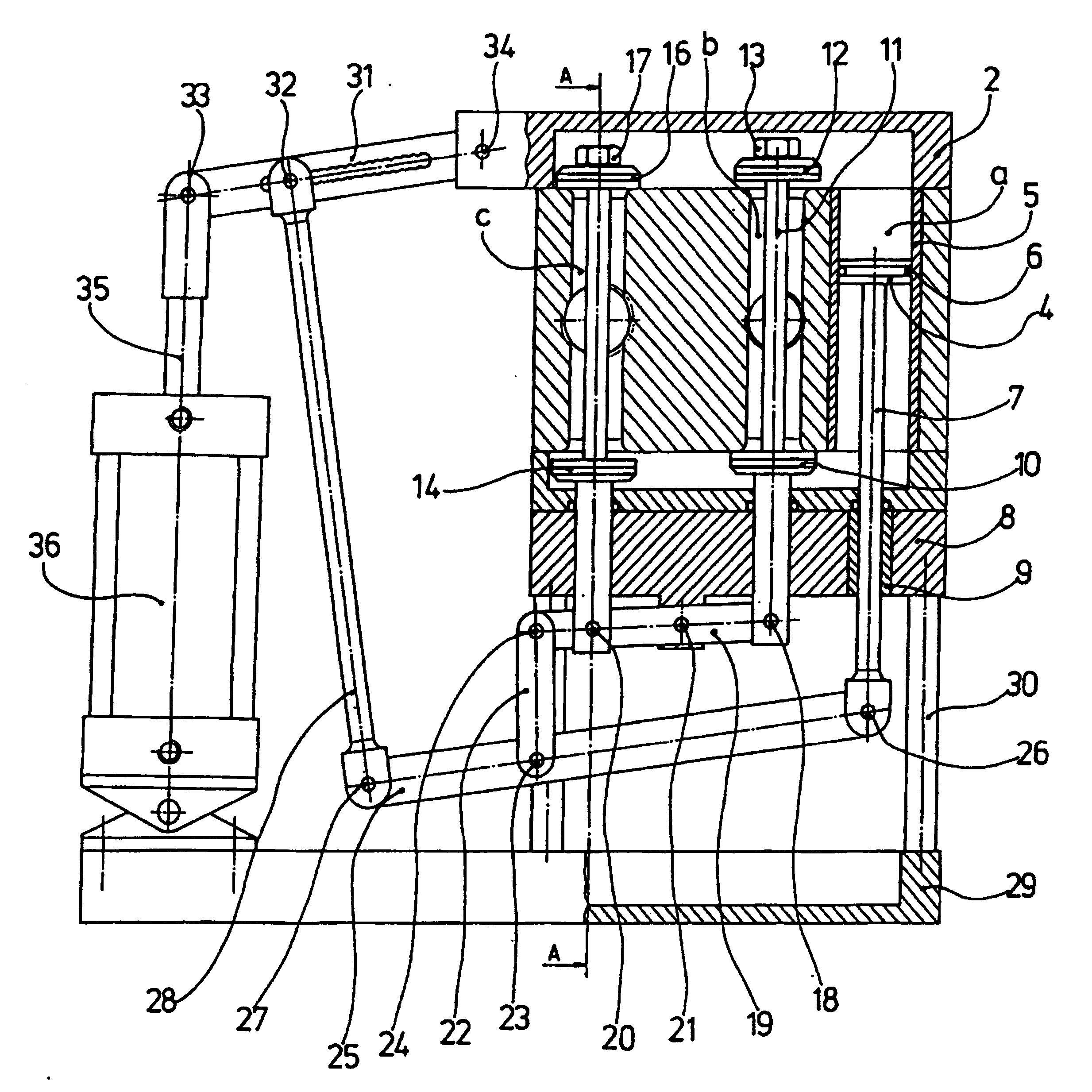

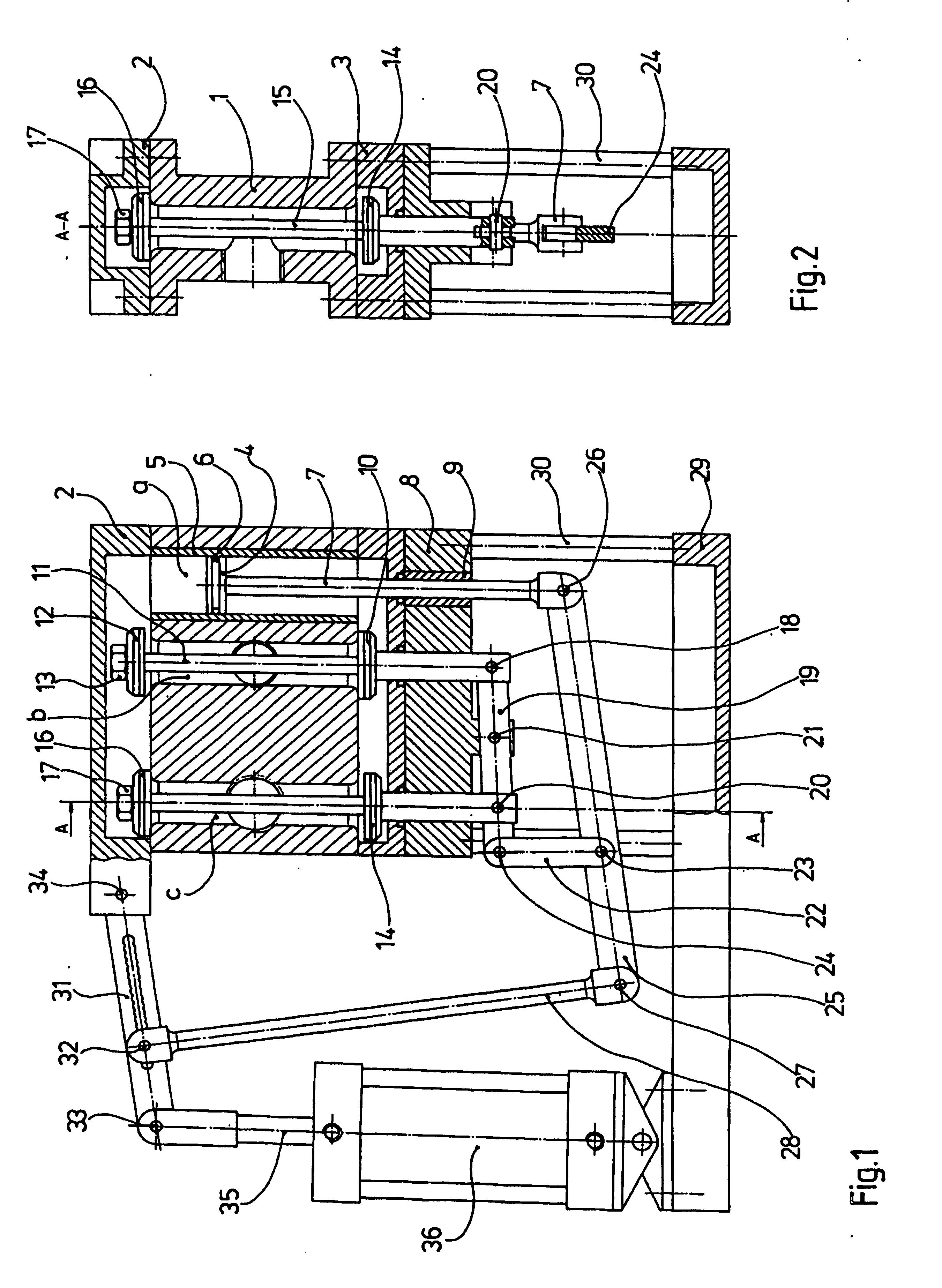

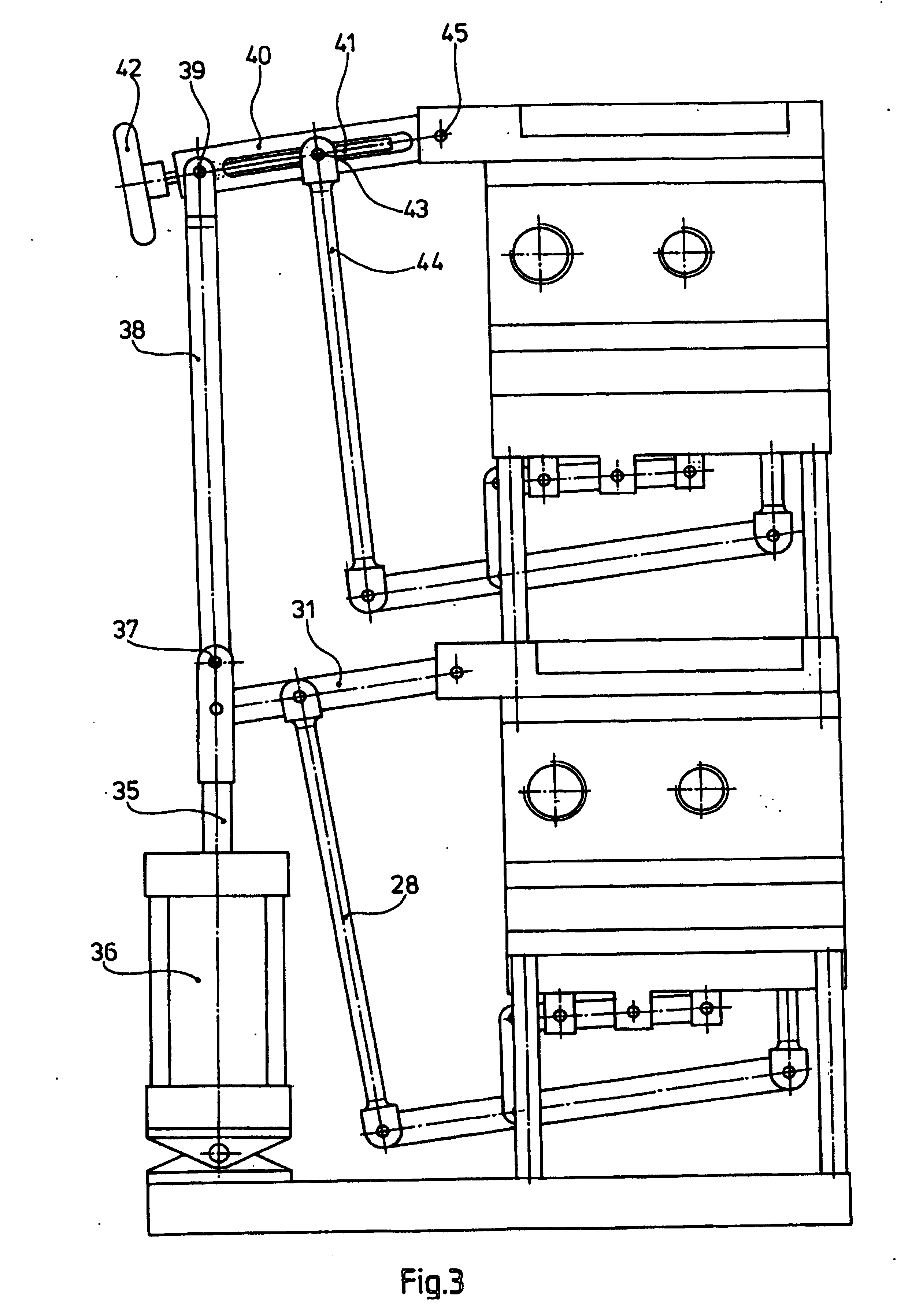

[0011] A pump casing 1, 2, 3 is illustrated in FIG. 1 with a pump cylinder 5 in which a piston pump 4 that is sealed with an O-Ring 6 is driven by a piston rod 7. The piston, sealed by an O-Ring 6 and a gasket 9 rod, pierces the pump casing 3 and the valve lid 8 with its end that faces away from the pump piston 4 and is connected at its end by a compensator 19 whose end is elongated and movably connects the valve rods 11, 15 to the conveying lever 25 through a plate 22. The conveying lever 25 pivots with anti-friction bushes 23, 26, 27, and is connected to the propelling lever 31 by a propelling rod 28. The propelling rod 31 is dissected in the middle so that the conveying lever 25 can be modified using a removable bolt 32 at its point of application. The pump piston's 4 stroke can thus be increased or reduced. The propelling lever 31 is connected in joints at one end to the pump lid 2 and with its other end to the piston rod 35 by bolts 33, 34. The piston rod 35 protrudes from a pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com