Thin-film solar cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

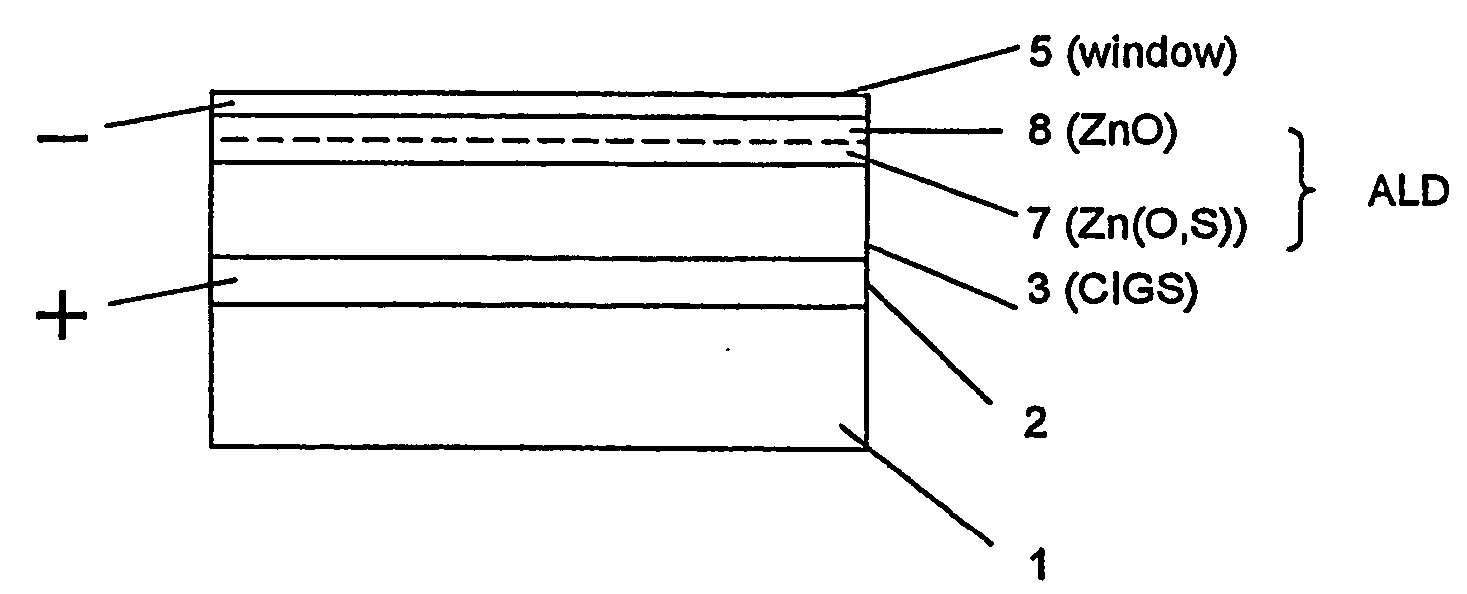

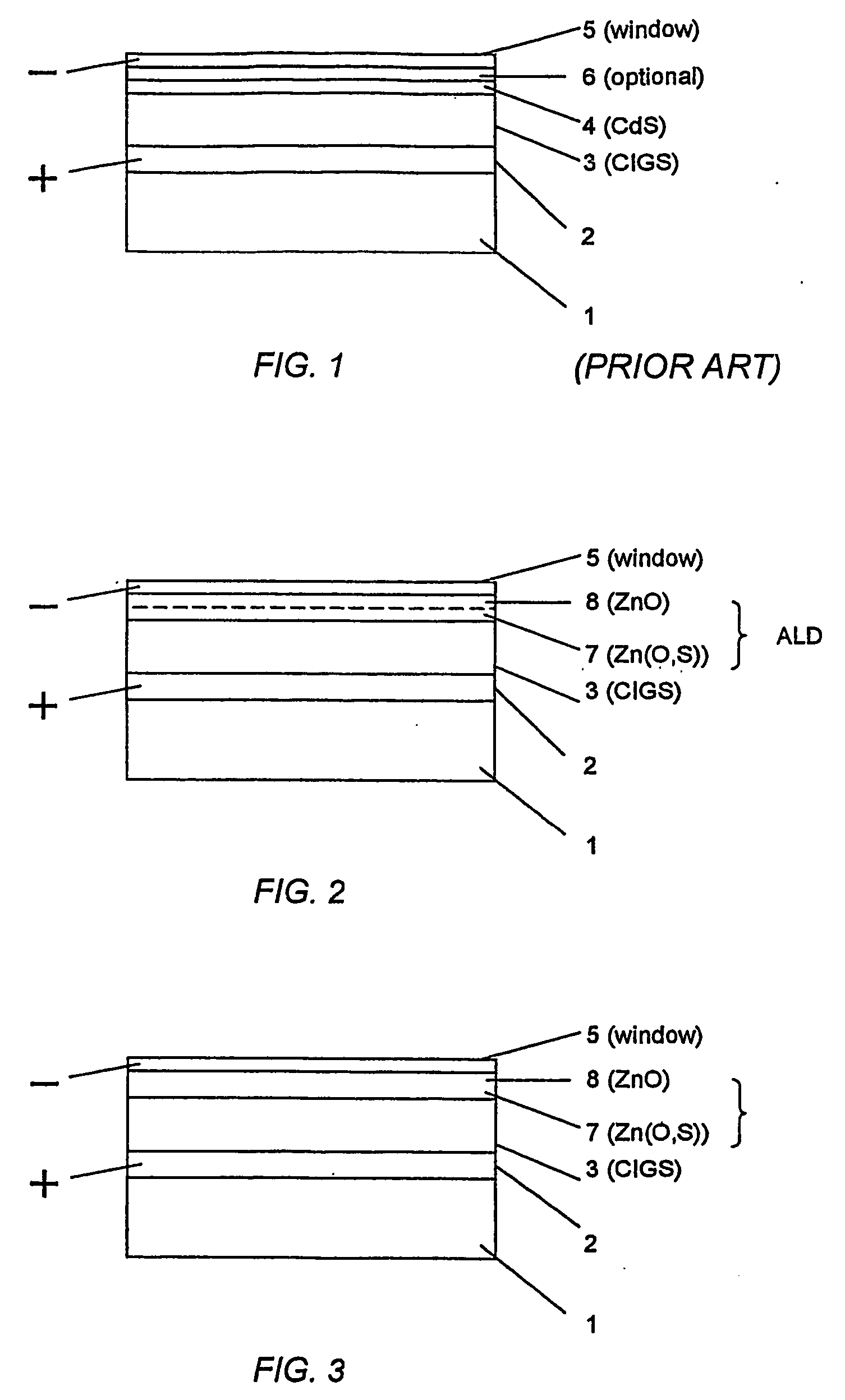

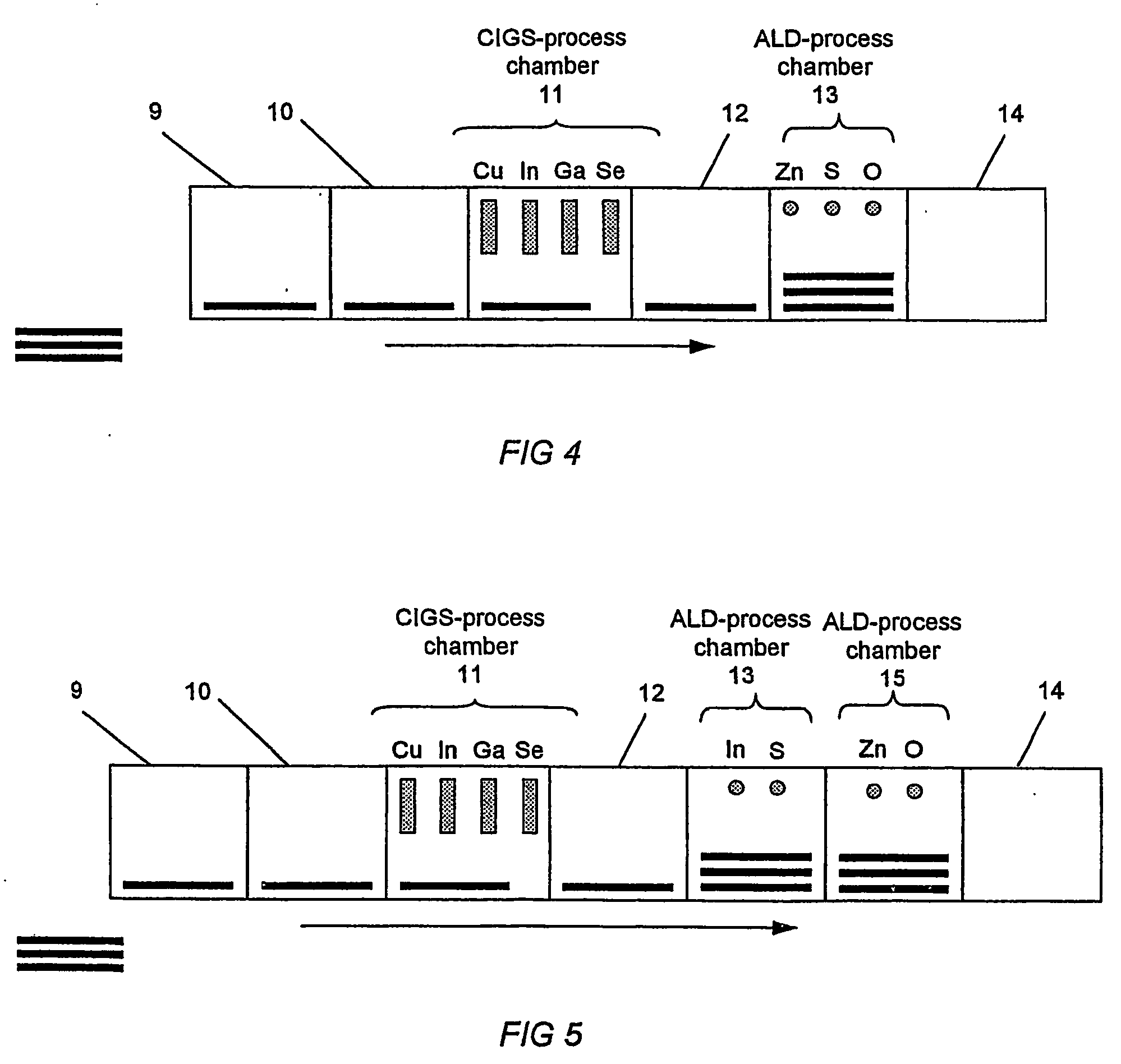

[0031] A CIGS-cell in accordance with the present invention is shown in FIG. 2. It comprises the usual glass substrate 1, the back contact layer 2 of molybdenum, the CIGS-layer 3 and the window layer 5. The usual CdS-buffer layer is replaced with two buffer layers, a first buffer layer containing Zn(O,S) deposited on the CIGS-layer and a second buffer layer 8 deposited on the first one and containing ZnO.

[0032] This is done in one process step in accordance with the invention. At first the Zn(O,S)-layer is deposited by atomic layer deposition (ALD) and immediately following this the ZnO-layer is deposited by A / D in the same process chamber. In effect, it can be considered that the two layers are replaced with one single layer of Zn(O,S), where no sulphur is added during the latter part of the deposition.

[0033] It is the inventive ALD deposition in the same chamber that makes possible the combination of a Zn(O,S)-layer and a ZnO-layer.

[0034] The function of the Zn(O,S)-layer is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com