Mold-casting structure and improvement method for grounding of the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

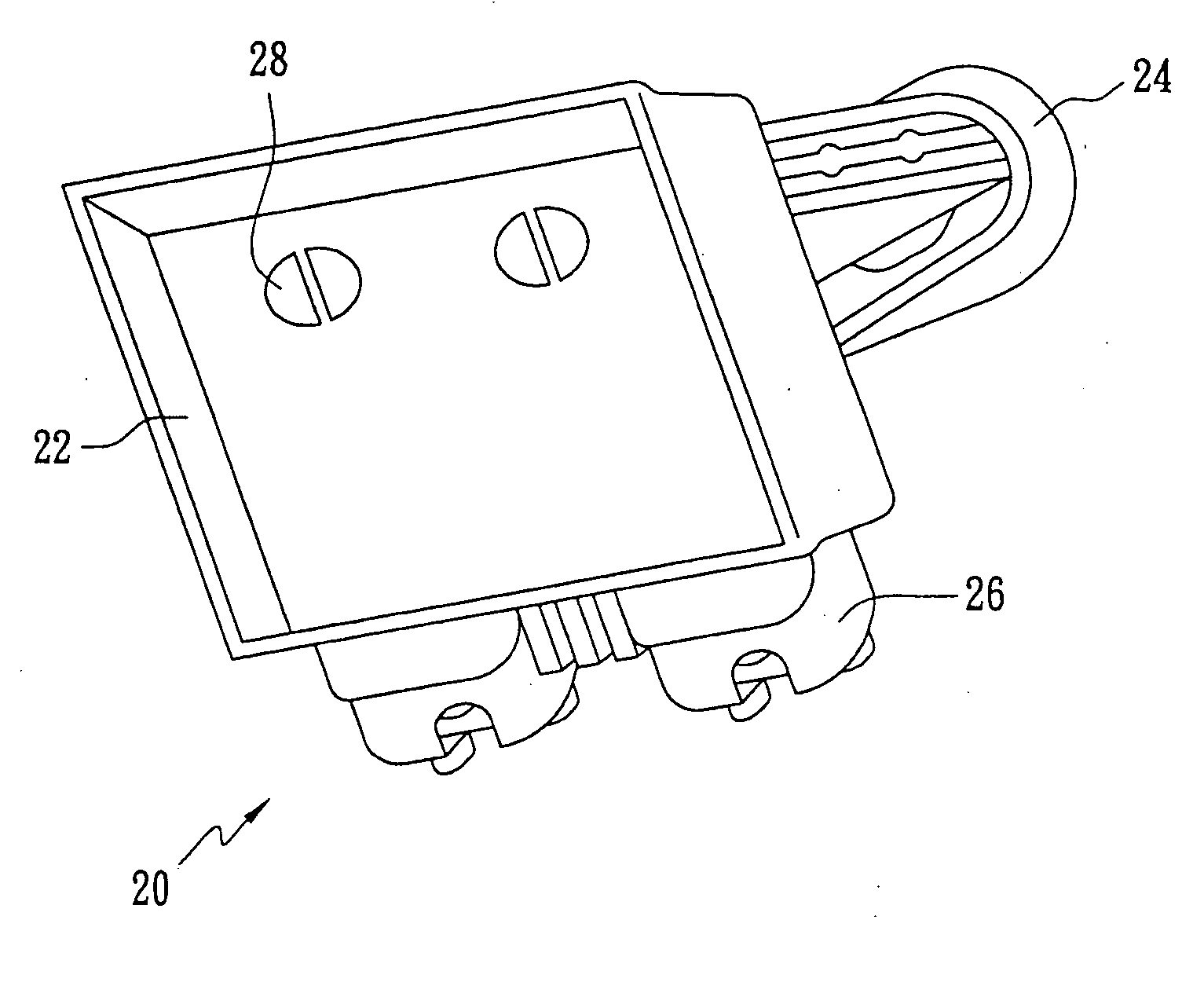

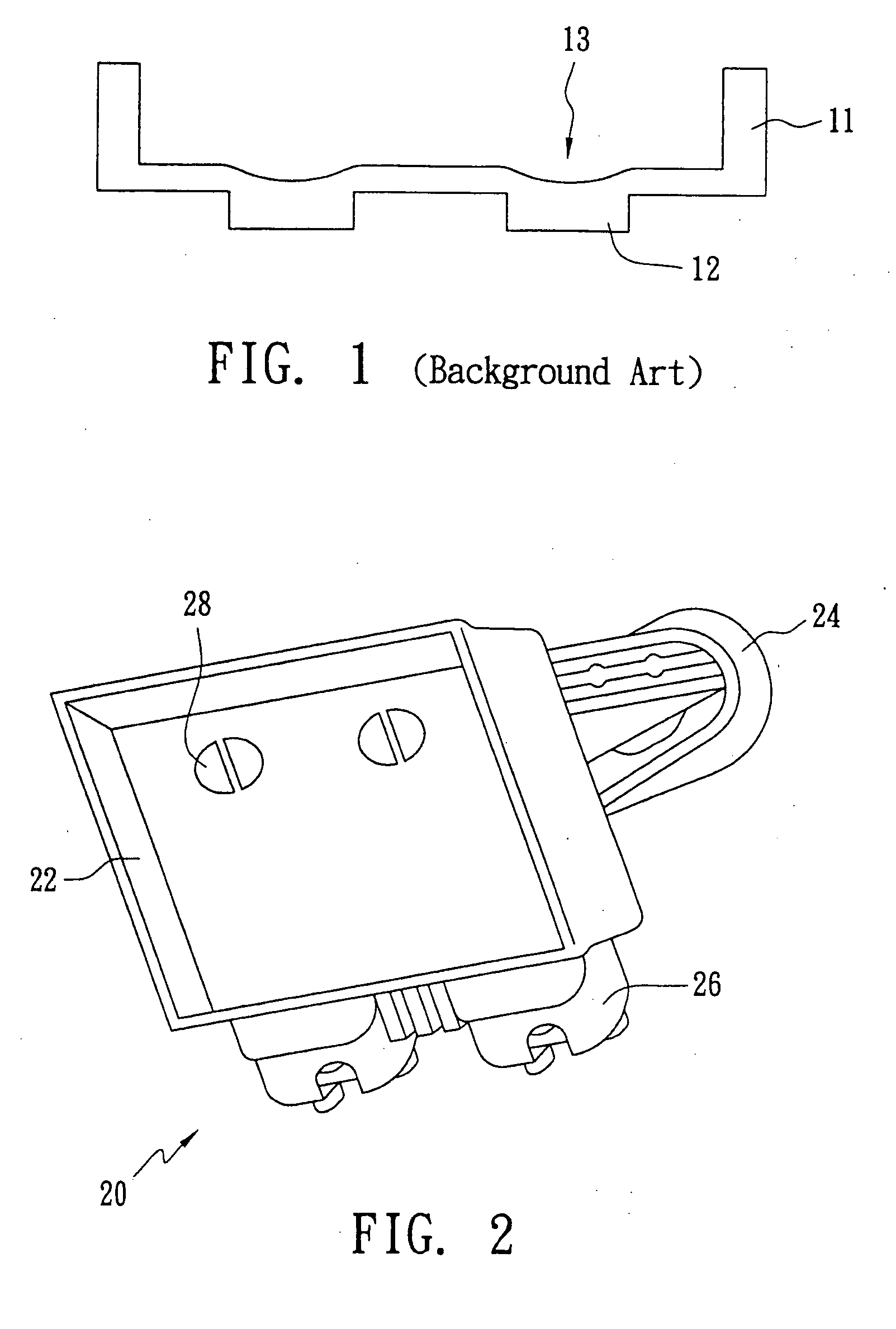

[0014] As shown in FIG. 2, an LNB structure 20 for microwave telecommunication comprises a housing 22, two horns 24, and two connector bases 26, where the housing 22, with the locations corresponding to the horns 24, is provided with two through holes shaped like semi-circles for the connection of signal cables to the horns 24. Only one horn 24 can be seen in FIG. 2, the other one is behind the housing 22 and thus not shown.

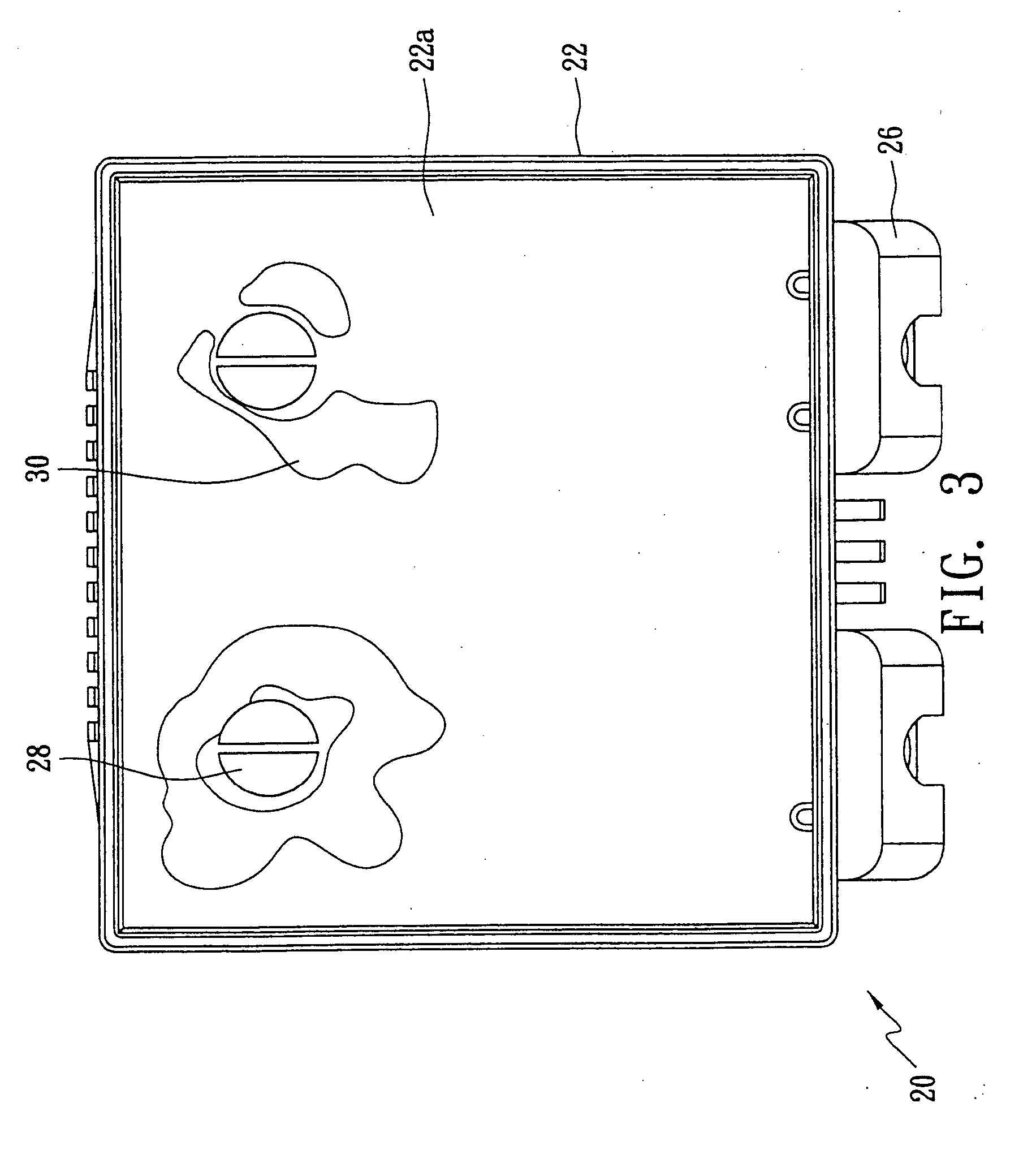

[0015]FIG. 3 illustrates the bottom view of the housing 22. After the LNB structure 20 is released from a mold and cooled down, a painting material such as a traditional paint, an ink marker or a red lead paint is daubed on the bottom surface 22a of the housing 22, and then scraped by a tool such as a scraper along a plane that is substantially equivalent to the bottom surface 22a but without protrusions or dishings. Accordingly, the paint on the protruded portions will be removed, so that the locations with remaining paint can be deemed dishings 30. In this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com