Pharmaceutical solution formulations for pressurised metered dose inhalers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

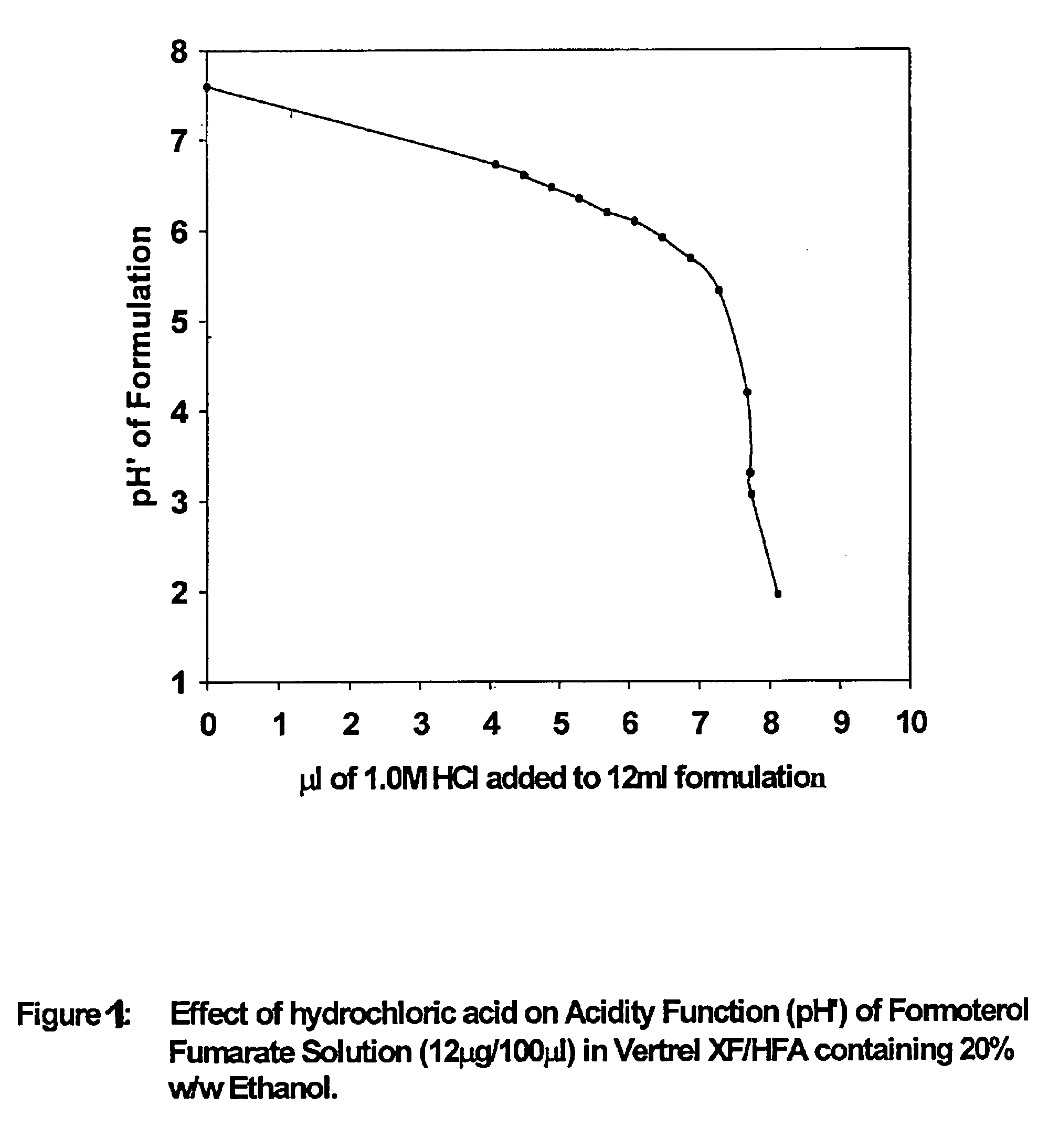

Effect of Hydrochloric Acid on Solution pH′ (Acidity Function)

[0092] (a) 1.0 M hydrochloric acid was added incrementally to 50 ml of HFA 43-10MEE (Vertrel XF) containing 20% w / w ethanol and the pH′ was measured after each aliquot of acid. FIG. 1 shows the resultant titration curve normalised to the usual fill volume of a pMDI can (12 ml). The pH′ profile exhibits a shallow negative slope to about pH′=5.5; thereafter the acidity function drops abruptly.

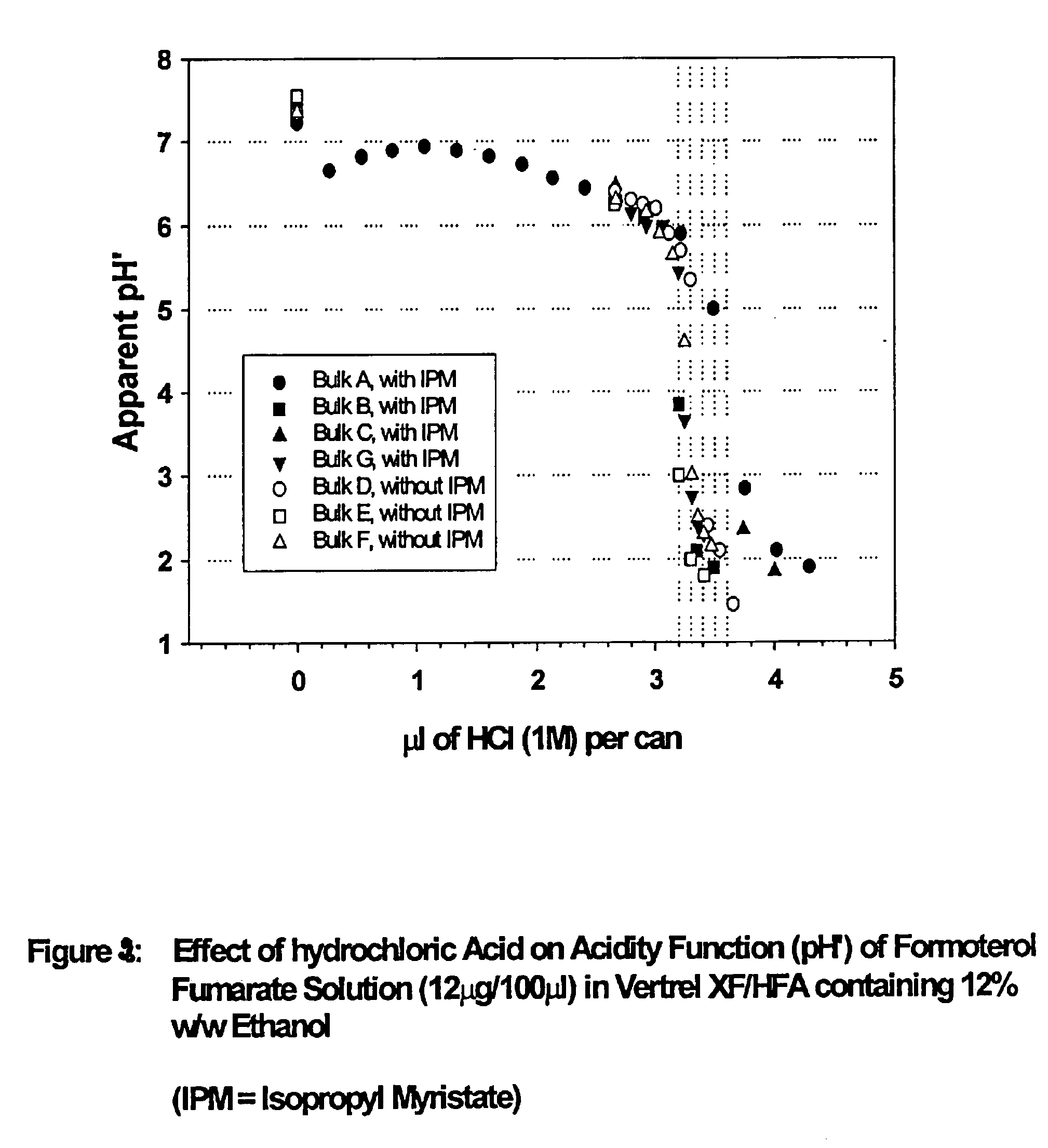

[0093] (b) Experiment (a) was repeated with formoterol formulations containing a lower concentration of ethanol (12% w / w) and with the addition of 1.0% isopropyl myristate. The resultant pH profile, for replicate bulk solutions, shown in FIG. 2 is similar in shape with the abrupt fall in pH′ per unit increment of acid again commencing at about pH′=5.5. However, only about half the acid is required to achieve the same reduction in pH′. This is largely due to the reduction in ethanol content; FIG. 2 also shows similarity in the profile...

example 2

Effect of pH′ on Stability of Formoterol Solutions in HFA 43-10MEE containing 20% w / w Ethanol

[0094] Aliquots of 1.0 M hydrochloric acid were added to 12 ml of formoterol solution in glass vials. After measurement of pH, valves were crimped on and the vials stored upright at 50° C. Vial samples containing different concentrations of acid were assayed for residual formoterol after 10 and 20 days storage. The pH′ of a third vial was determined after 40 days storage. The results are shown in Table 1. Table 1 shows changes in pH on storage; this is probably largely associated with leaching of alkali from the soft glass of the vials. However, overall consideration of the pH′ and formoterol content data implies that the stability of a solution formulation of the drug in HFA can be improved by the addition of mineral acid to provide a formulation with pH′ between 2.5 to 5.0.

TABLE 1pH′ and Formoterol Content of Formoterol-Vertrel XF / HFA Solutions(12 μg / 100 μl)Vehicle: Vertrel XF / HFA with ...

example 3

Stability of Acidified Formoterol-HFA 134a Solutions in Anodised Cans

[0095] Formoterol formulations (12 μg / 100 μl) were prepared by dissolving 1.44 mg of formoterol fumarate in HFA 134a containing 12% w / w ethanol with and without 1.0% w / w isopropyl myristate. The latter was included as a non-volatile excipient with the potential for increasing MMAD if so desired. It also improves the solubility of formoterol in the vehicle and reduces polarity of the vehicle compared to the addition of glycerol.

[0096] pMDI cans containing 3.1 to 3.4 μl 1.0 M hydrochloric acid were set down on storage, upright and inverted, at 4° C. to 50° C. and samples taken for analysis of formoterol content at appropriate intervals.

[0097] Stability data obtained after 70 days of storage are given in Table 2.

[0098] A matrix of formulations containing 1.44 mg (12 μg / 100 μl) formoterol fumarate were prepared in HFA 134a containing 12.0% w / w ethanol with or without 1.0% w / w isopropyl myristate as non-volatile exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com