Pre-stressed modular retaining wall system and method

a modular and pre-stressed technology, applied in the direction of excavations, artificial islands, roads, etc., can solve the problems of inability to provide optimal solutions for available retaining walls, lack of rapid construction, and small construction footprint, and achieve optimized mix design and control, the effect of improving the quality of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] Reference will now be made in detail to the present preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. The exemplary embodiments of this invention are shown in some detail although it will be apparent to those skilled in the relevant art that some features may not be shown for the sake of clarity.

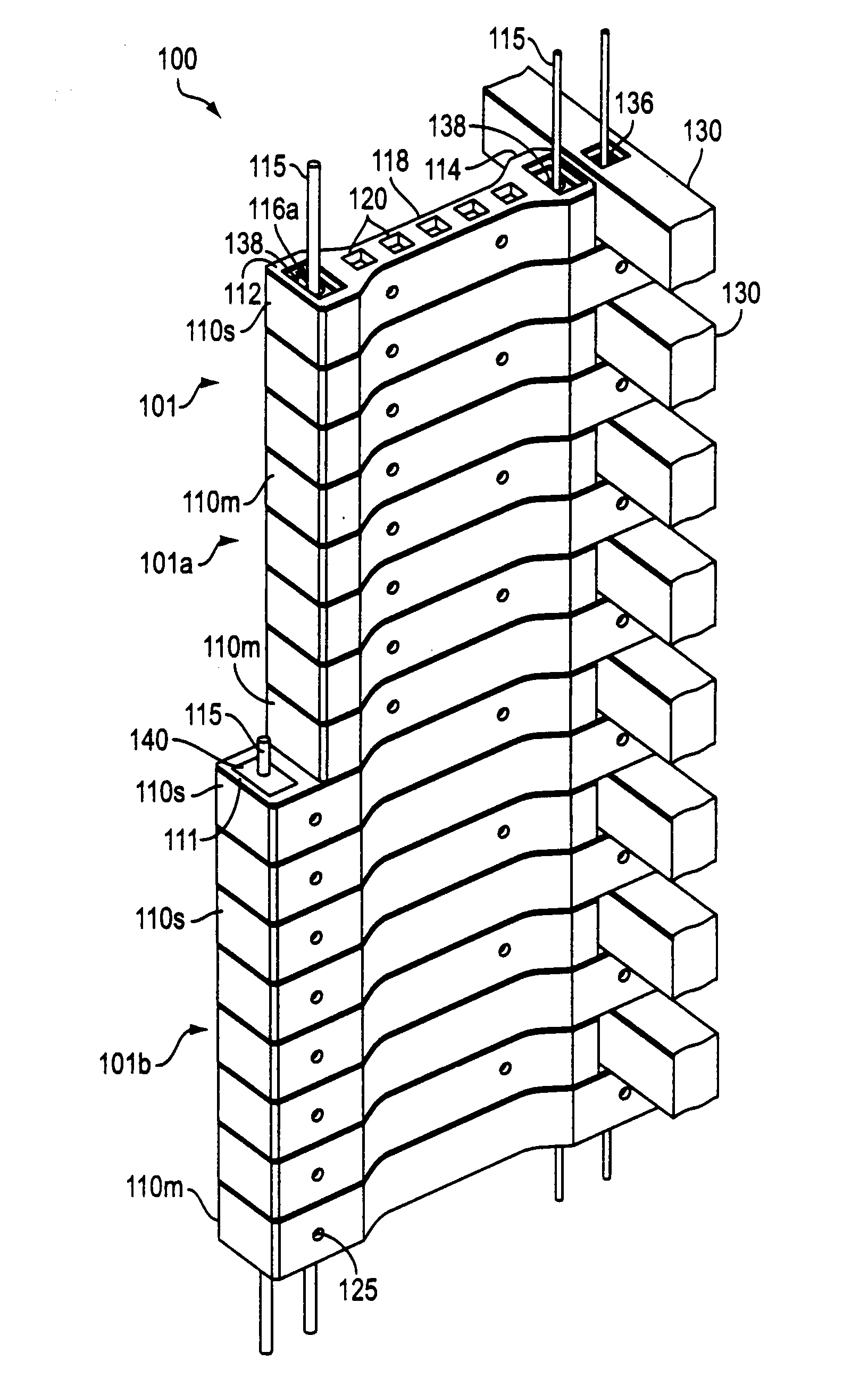

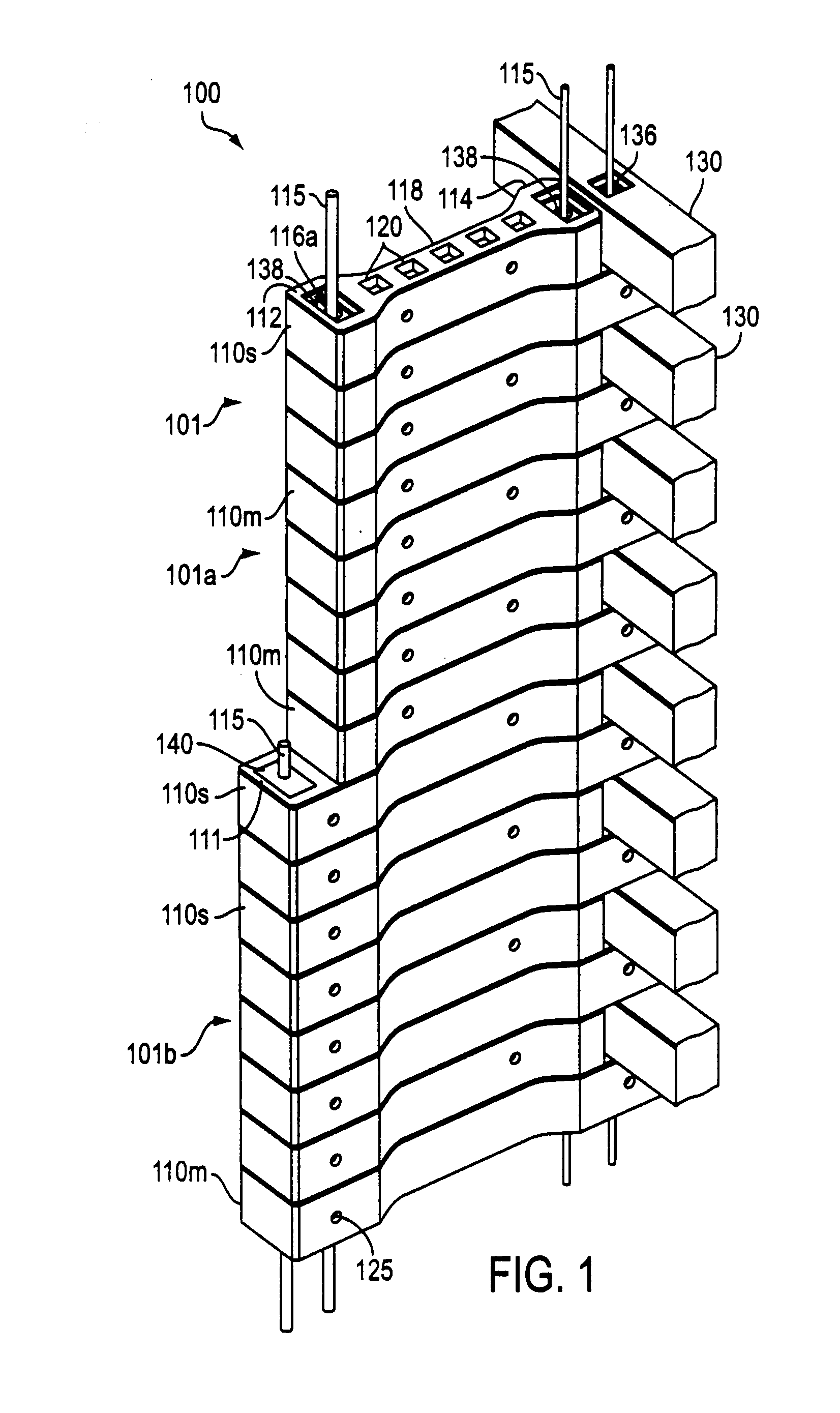

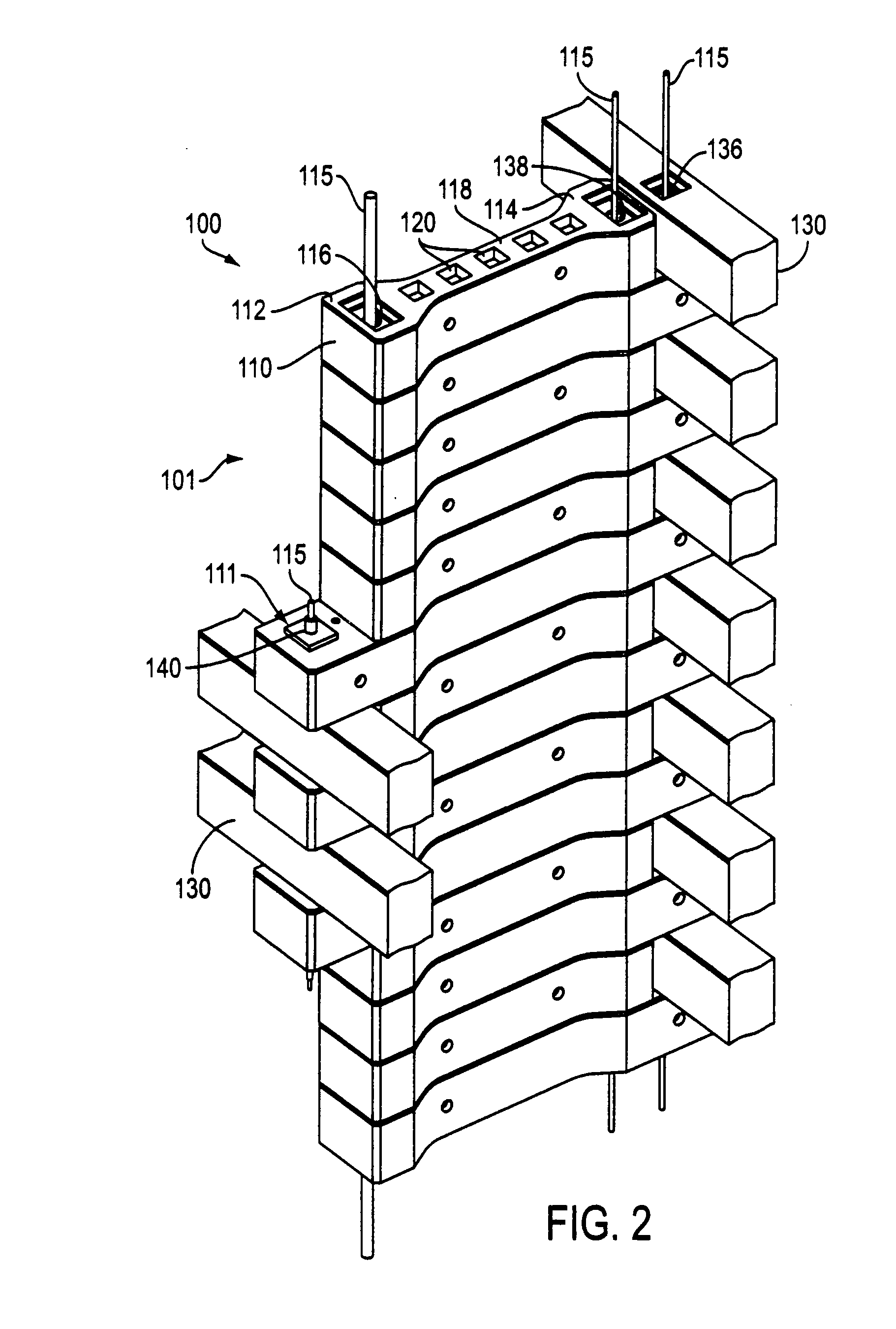

[0118] The systems of the preset invention possess fundamental characteristics that are common to all of the constituent groups (i.e. subsystems). The systems are preferably comprised, at least partially, of pre-cast concrete components, called headers 110 or header units 110. These components, when stacked one on top of the other, form header stacks 101. These header stacks 101 are then augmented in a variety of ways. The augmenting members generally form secondary structural members 130. These components are secondary in the sense that they are available to resist soil loading, directly transferring these loads to the primary st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com