Product dispensing systems

a technology for product dispensing and products, applied in the direction of liquid dispensing, containers, pliable tubular containers, etc., can solve the problems of environmental damage, extreme flammability of nature, and general phase out of propellant gases, and achieve the effect of reducing the chang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

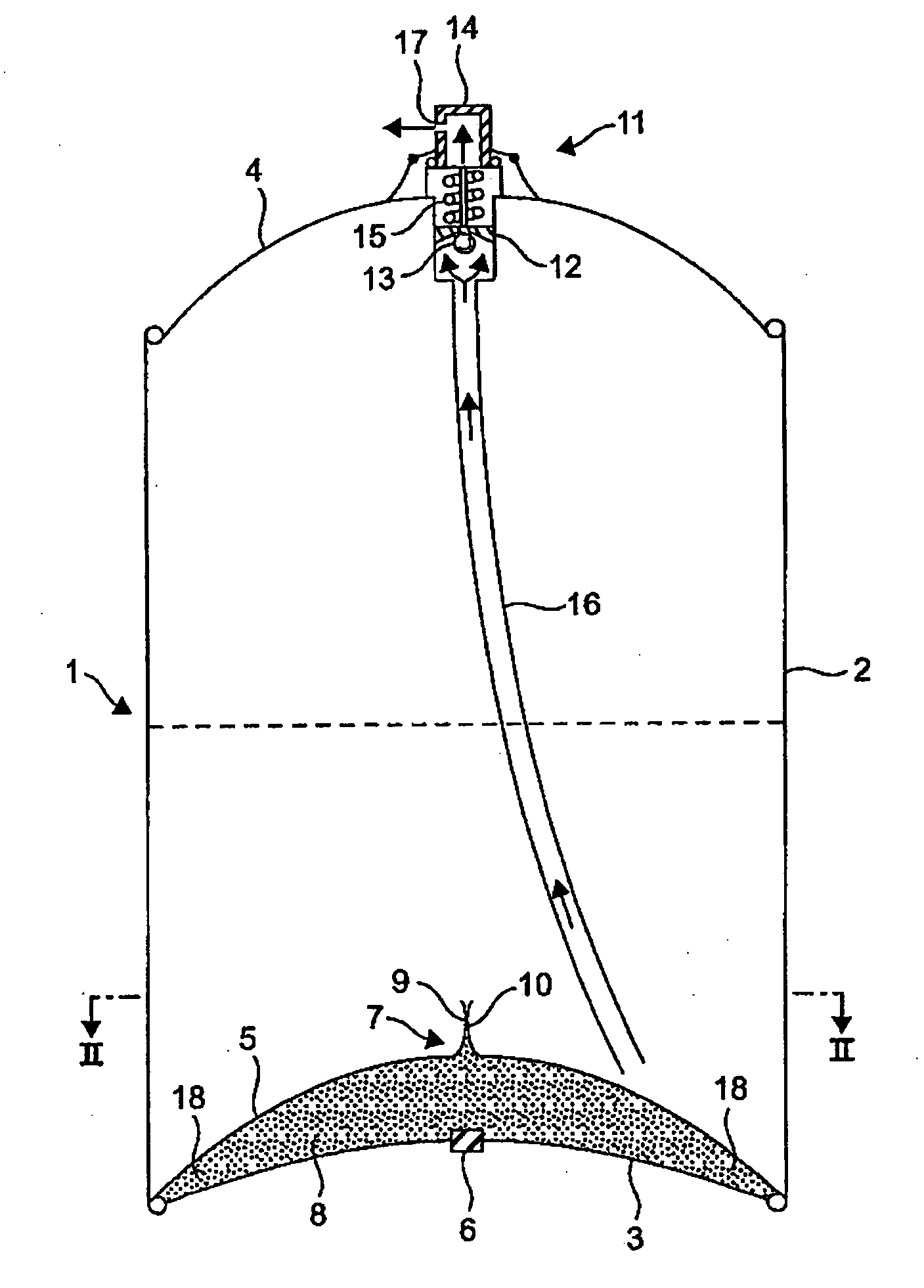

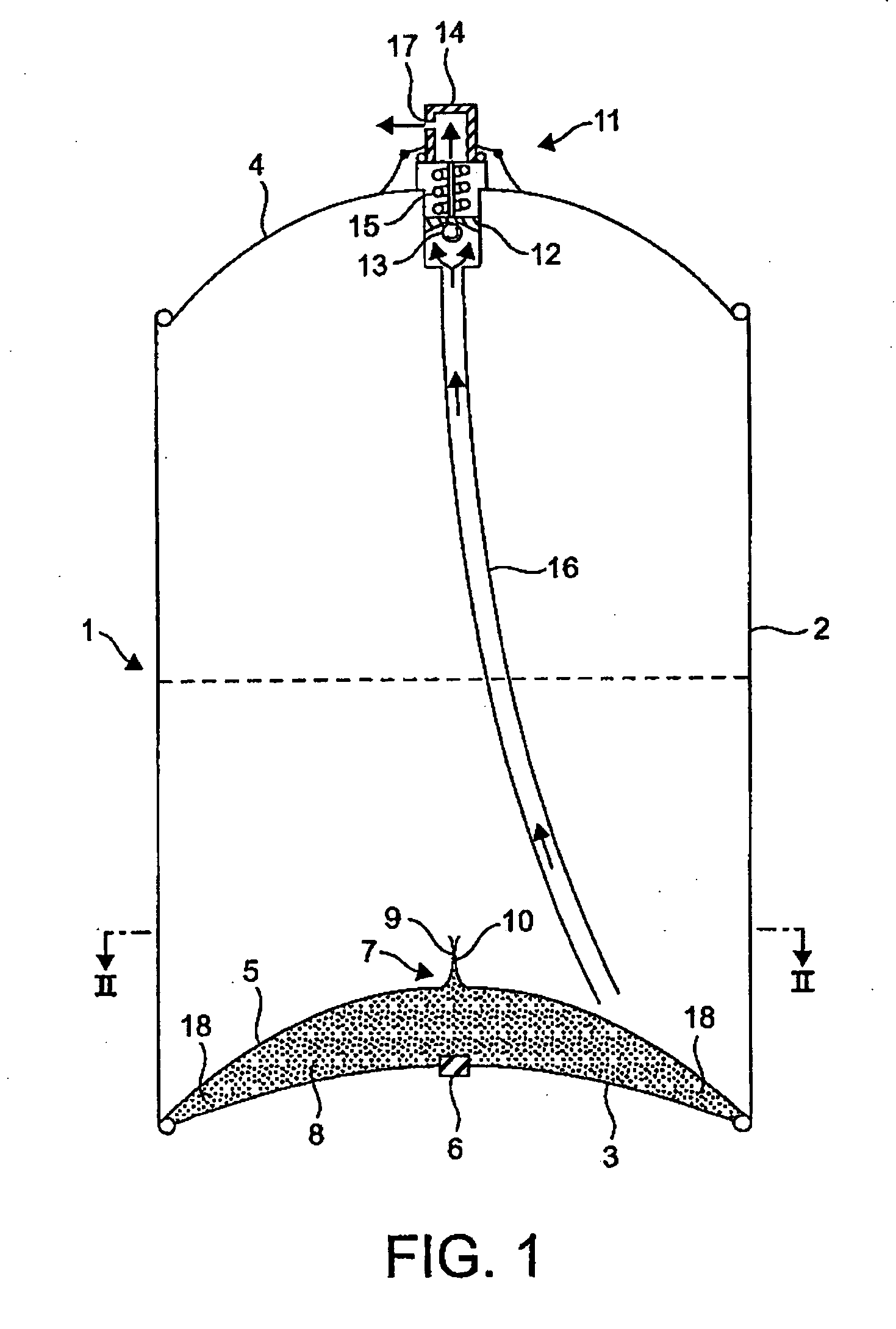

[0099] With reference to the drawings and to FIG. 1 in particular, there is shown a canister 1 incorporating a pressure pack dispensing system of the invention. The canister 1 comprises a cylindrical main body portion 2, a circular base portion 3 of concave shape (external view) and a circular top portion 4 of convex shape (external view), all made of aluminum alloy material.

[0100] The base portion 3 is sealingly crimped around its periphery to the lower edge of the main body portion 2 in a manner known per se for aerosol canister in particular.

[0101] Sandwiched and sealingly held within the crimped structure between the main body portion 2 and the base portion 3 is a circular partition 5 made of plastic and having a greater concavity shape than the base portion 3.

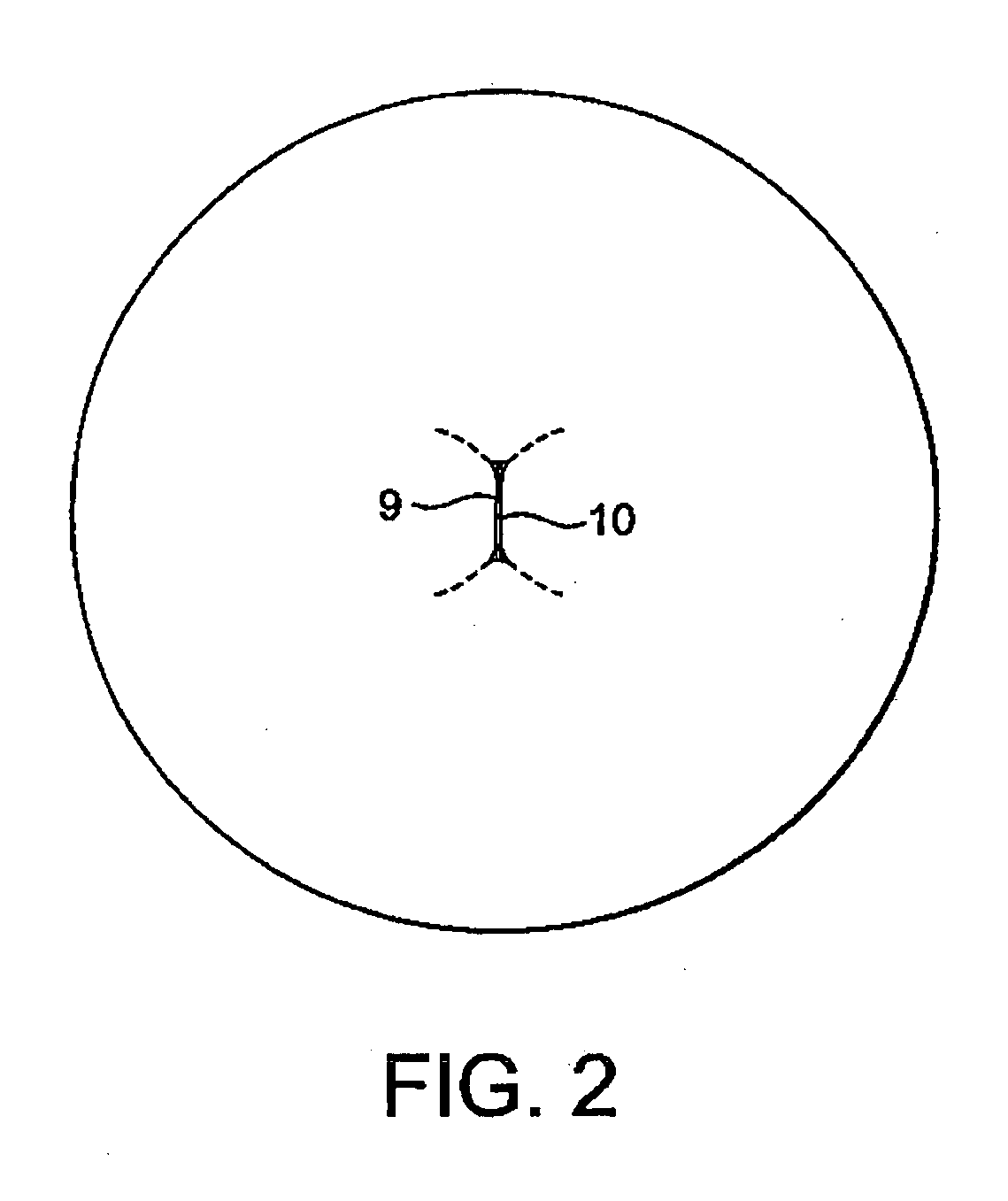

[0102] The base portion 3 has a small circular “bung”6 at its centre made of rubber (or other elastomer) and the partition 5 has an upstanding one-way valve 7 allowing for the flow of fluid from a compartment 8 formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com