Collector and separator apparatus for lawn and garden

a technology for collecting and separating equipment, which is applied in the field of apparatus for collecting and reducing yard debris, can solve the problems of not being able not being able to effectively collect leaves and other debris close to the ground, and not being able to solve the problem of difficult to collect thick layers of debris, particularly deep piles of leaves, and reducing the effectiveness of vacuum pick-up openings. , the effect of reducing the effectiveness of the vacuum opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0393] A commercially marketed machine made according to the design shown in U.S. Pat. No. 5,642,864 was used to collect leaves on a lawn and shred them. The machine had an intake opening about 25 inches long and 4 inches wide with the damper at its maximum open position. The opening was inclined forward at about 45 degrees to the ground, giving an effective opening height of about 2.8″. The chamber behind the damper was a solid rectangle in shape and about six inches front to back. A straight rectangular duct led from an opening in one end of the chamber to the center of a chipper-shredder-blower having its axis of rotation perpendicular to the direction of forward movement. The blower discharged into a large bag made of thick cloth and having a mesh-covered opening for venting entraining air. A zipper opening was provided for emptying collected debris.

[0394] A covering of fresh, dry leaves about three to six inches deep was present on the lawn. In addition, piles of leaves about ...

example 2

[0397] Following the experience of example 1, collecting leaves with a conventional 26-inch, two-stage snow blower was attempted to see if the auger-feed mechanism would-function with leaves. Indeed, the auger readily fed even the deepest piles of leaves into the second-stage blower, which blew them 10-15 feet away. However, this approach left a thin layer of leaves and other debris on the lawn where the pick-up auger had passed.

[0398] The conclusion was that a machine with a similar auger-feed pick-up would collect even deep piles of leaves. However, the user would need to go over the lawn a second time with a different machine to collect the thin layer of residual leaves and other debris.

example 3

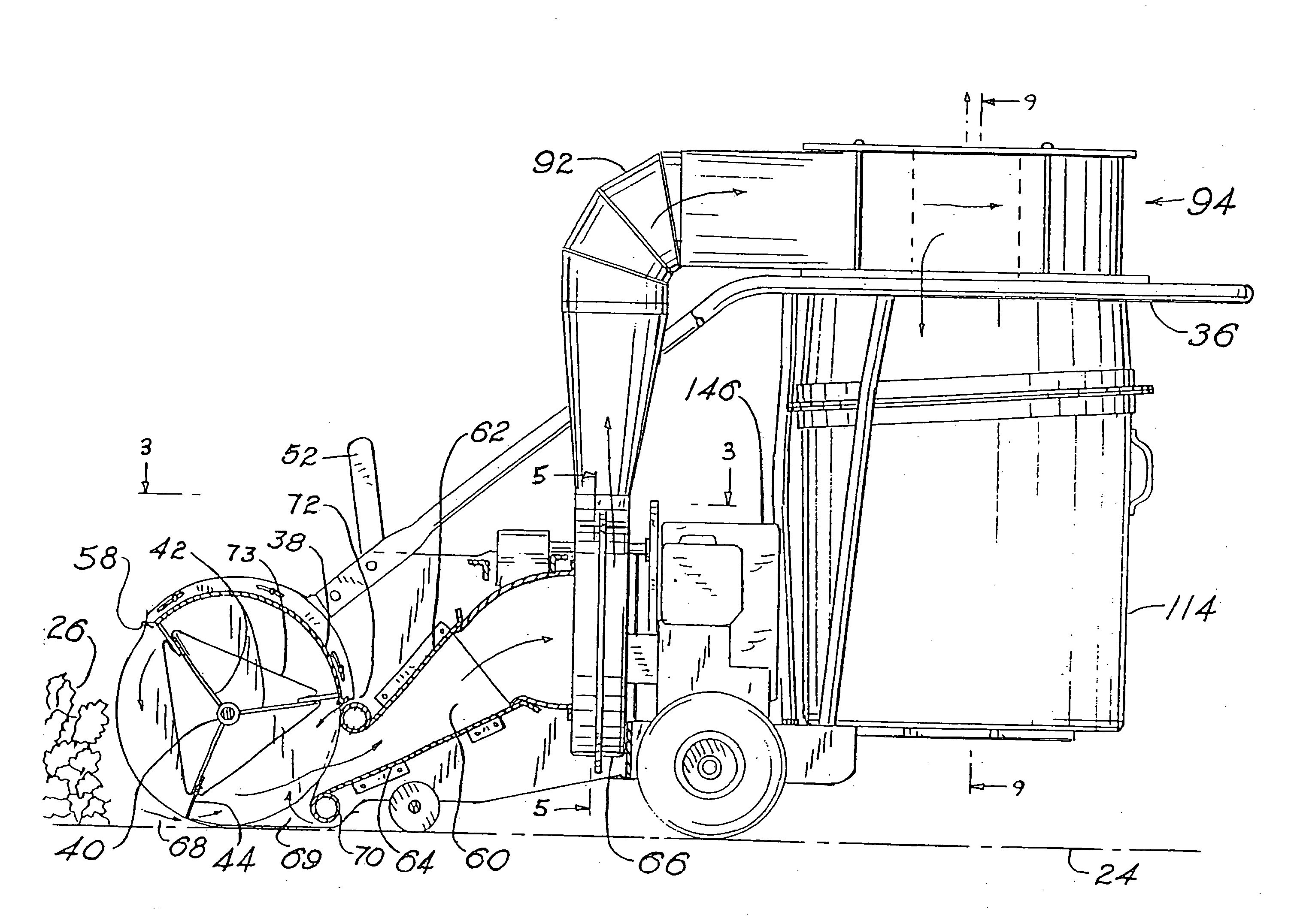

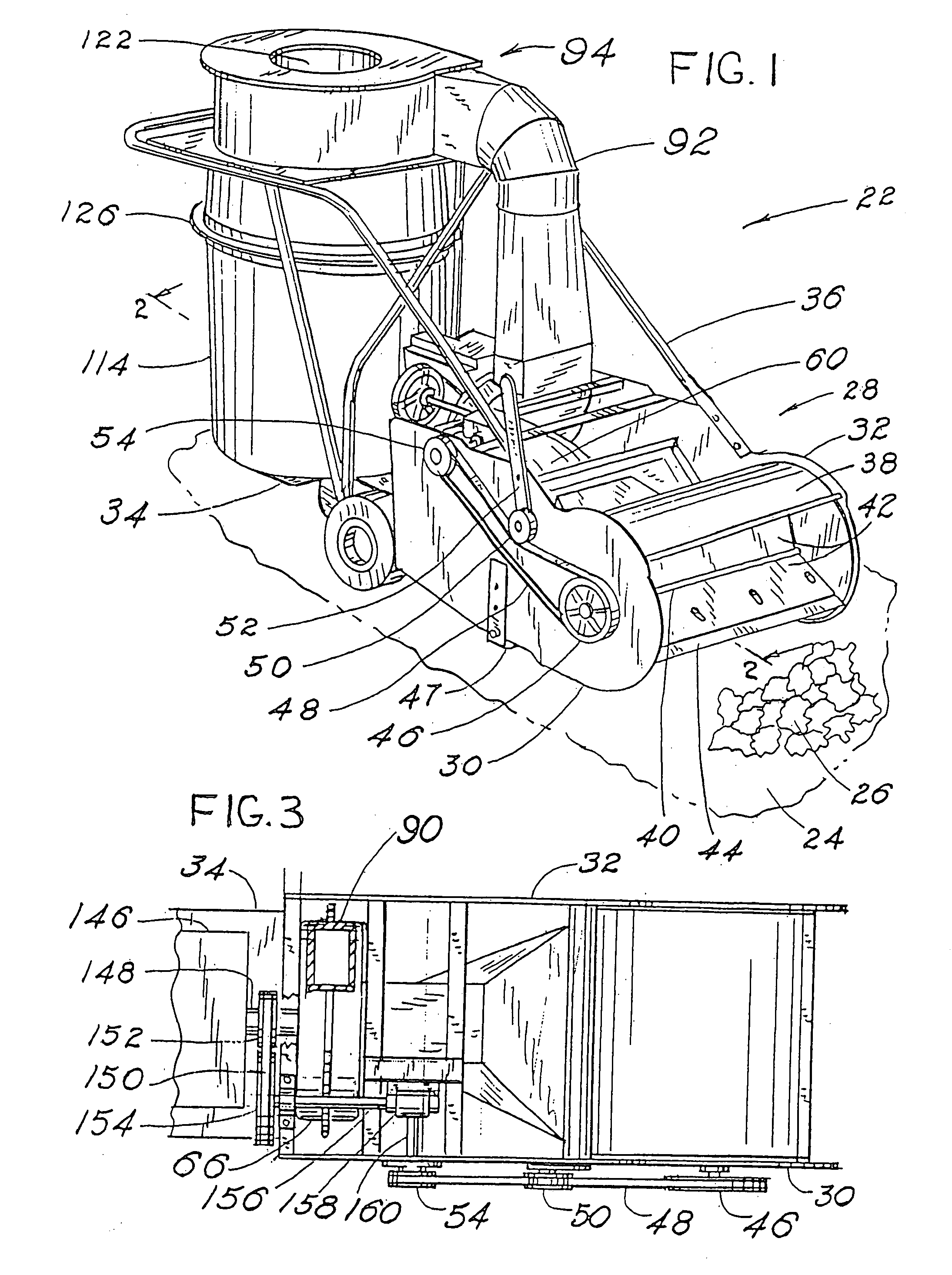

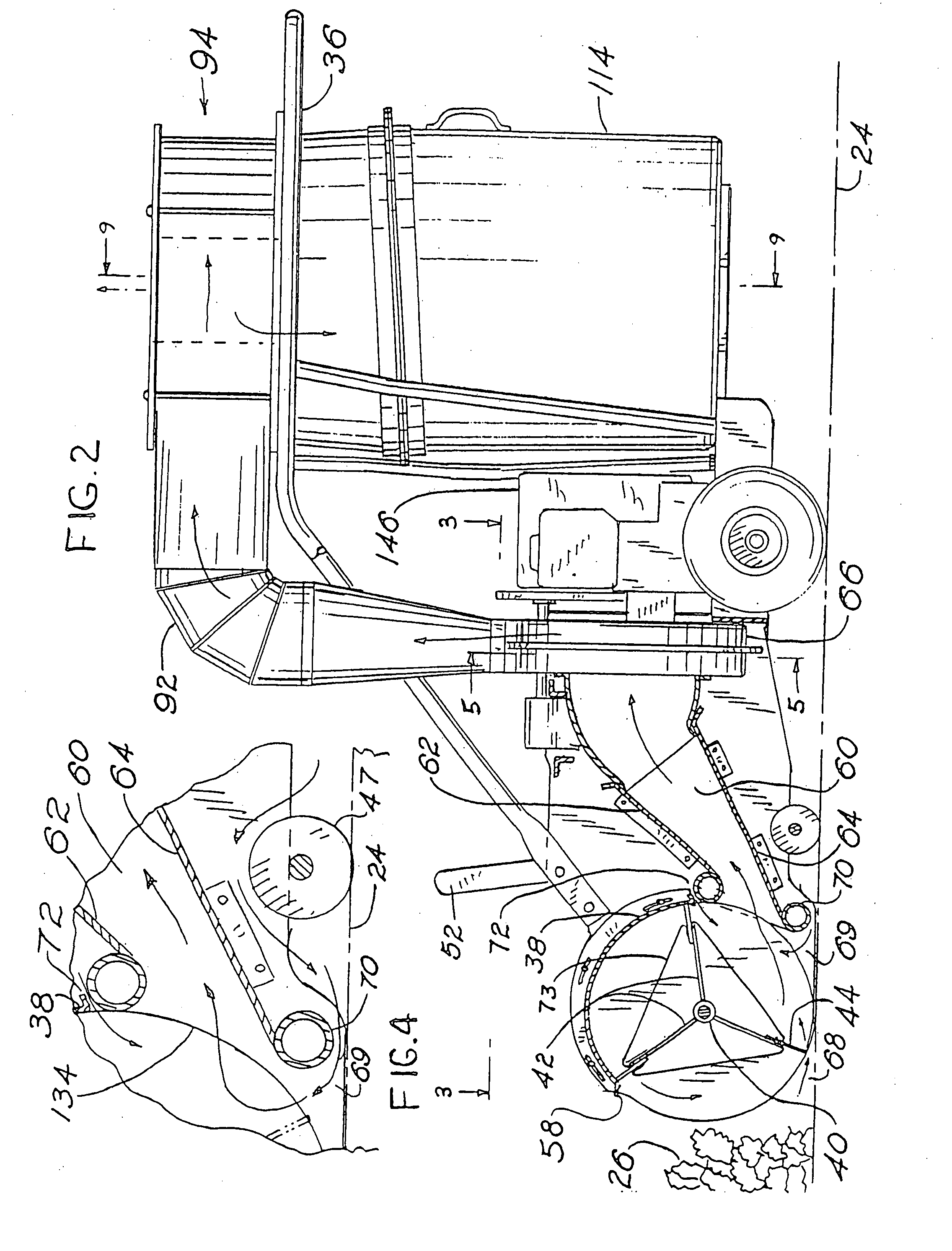

[0399] A machine of the current invention was built according to the drawings in FIGS. 1-11. A Yard Man 5-horsepower chipper-shredder-vacuum machine built by MTD Products was purchased; the chipper-shredder unit and attached drive motor were removed from the purchased machine; and then they were mounted on the base plate of the current machine. The machine width between the left side support plate and the right side support plate was 24.″ The collector rotor diameter was 15″, and it turned 65 revolutions per minute. The front, upper edge of the housing over the rotor was about 13½″ above the support surface. The lowermost portion of the lower collector lip was about 1″ above the supporting surface when measured with the machine sitting on a concrete slab. The collector duct had an entrance opening 2½″ high and 24″ wide with a cross sectional area of 60 square inches, an exit opening about 6″ high and 9″ wide with a cross sectional area of about 54 square inches, and a convergence an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com