Injection-molded plastic container with improved stacking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

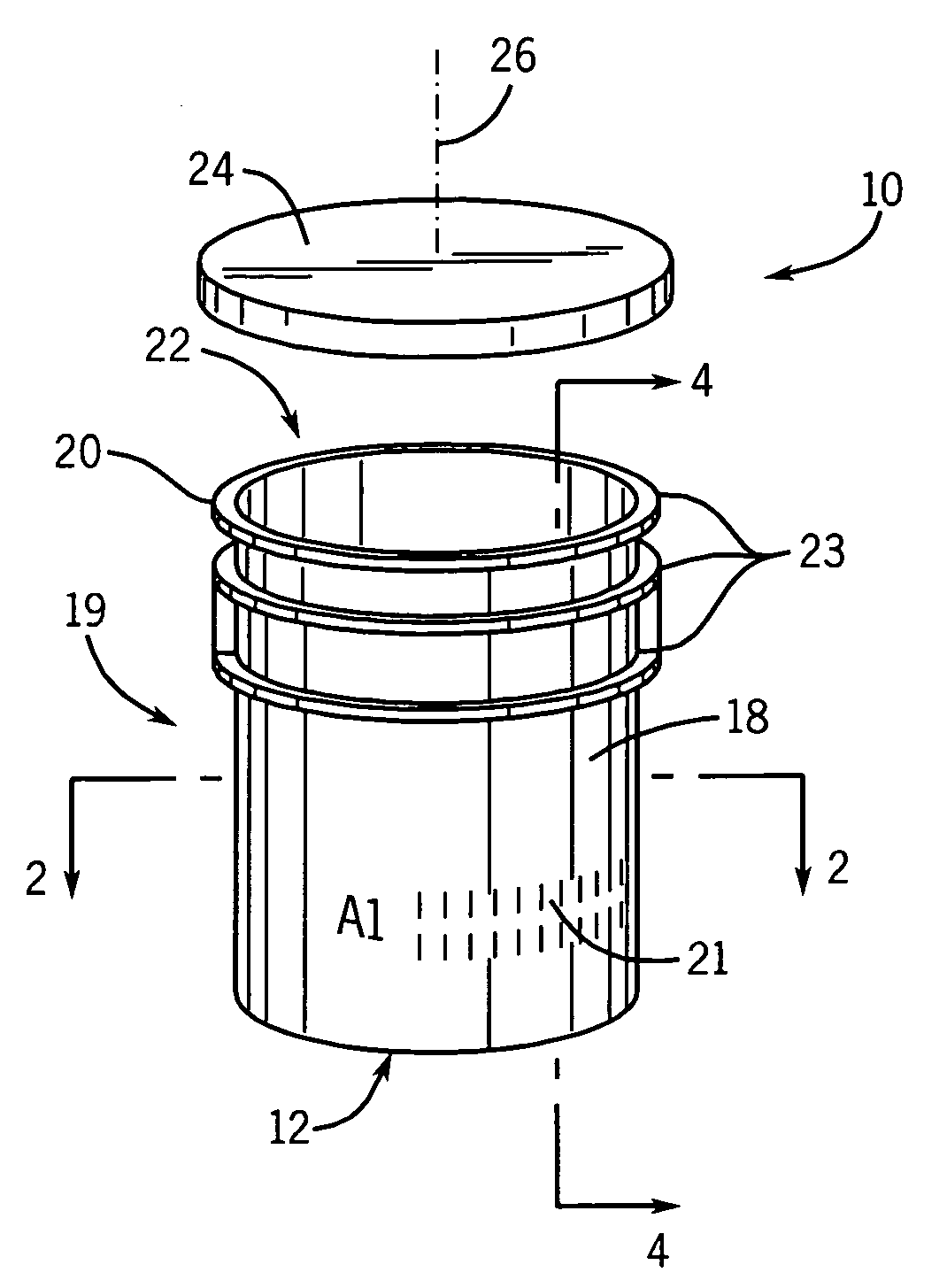

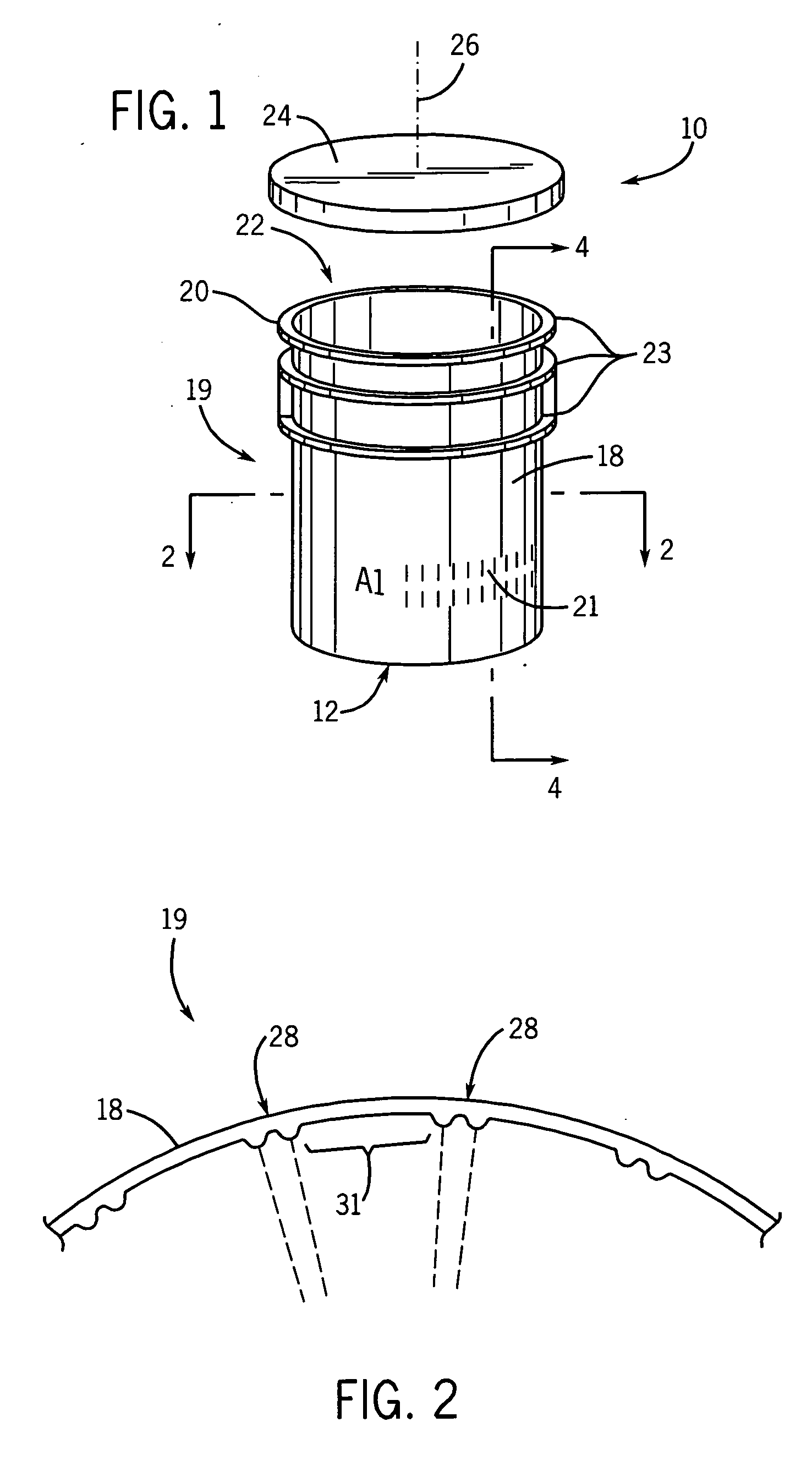

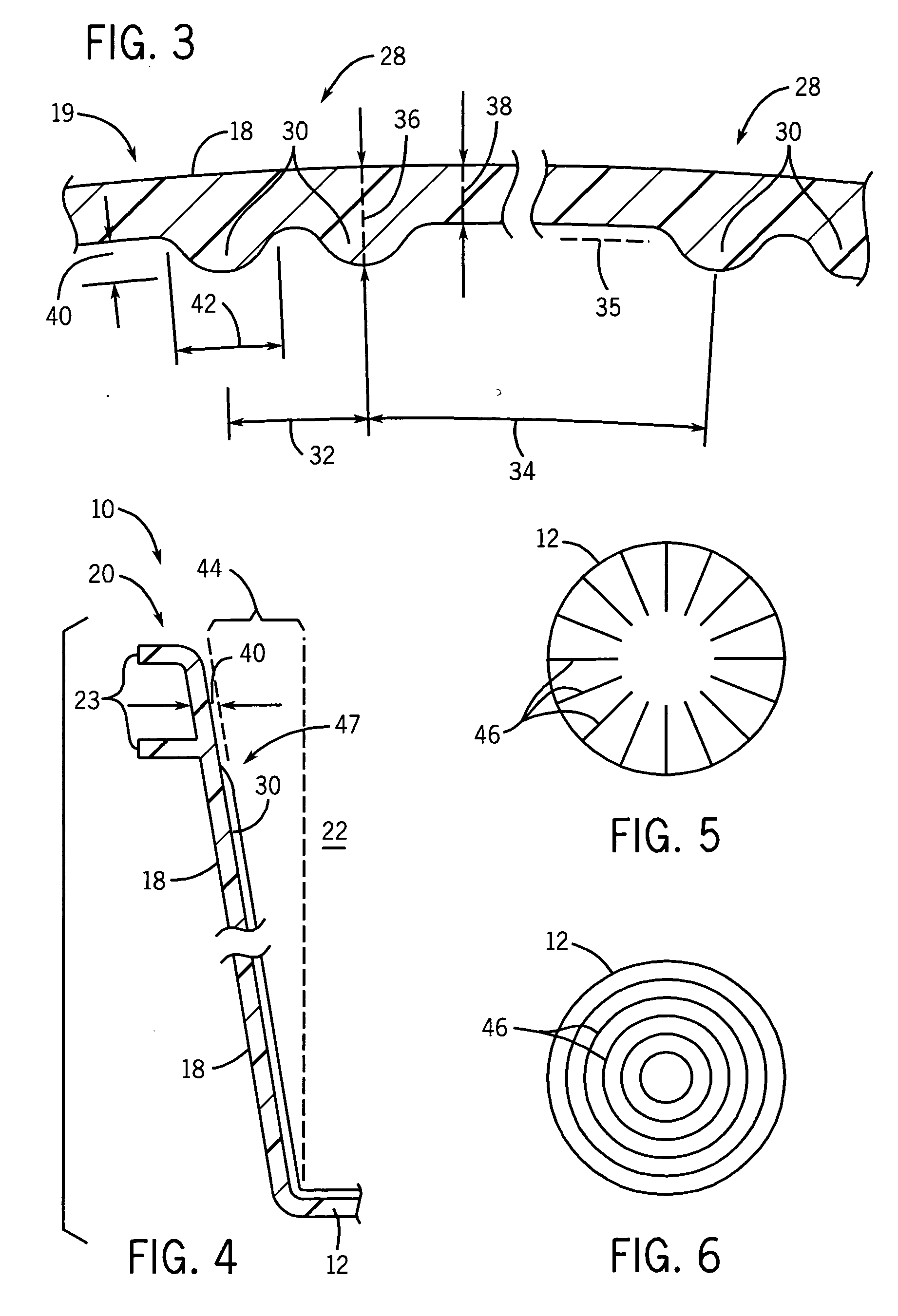

[0046] Referring now to FIG. 1, a container 10 of the present invention may provide a generally planar base 12 forming the bottom of the container 10. Attached at the periphery of the base 12 are upwardly extending sidewalls 18. The sidewalls 18 terminate at an upper rim 20 and may be sealed by attachment of a lid 24 to the upper rim 20 of the sidewall 18 to enclose a container volume 22. Each of the base 12, sidewalls 18 and lid 24 may be injection molded of a thermoplastic material such as a high density polyethylene, or polypropylene, or copolymers although other polyolefins may be used.

[0047] An outer surface 19 of the sidewalls has a smooth circular cross-section that may be contact printed, for example, using transfer or silkscreen printing with information 21 for the consumer. Rims and flanges 23 may be formed in the outer surface 19 to provide attachment points for the lid 24 and supports for handles (not shown) and the like.

[0048] When filled with a product (not shown) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com