Sewage lift mechanism with remote alarm

a technology of sewage lift and remote alarm, which is applied in the direction of sewer systems, non-positive displacement fluid engines, constructions, etc., can solve the problems of high failure rate of lift station alarm, high false alarm rate, and overflow of sewag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

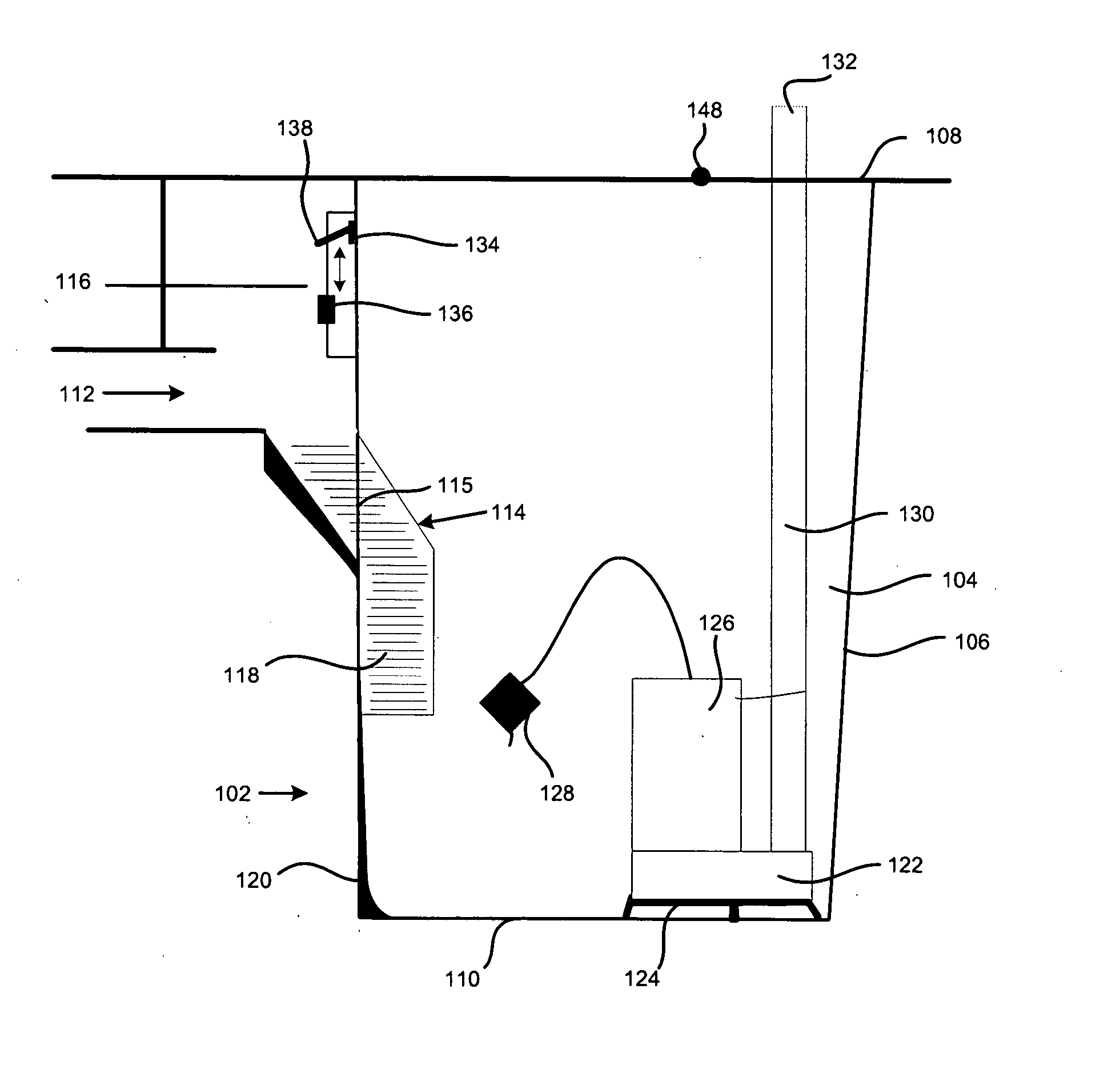

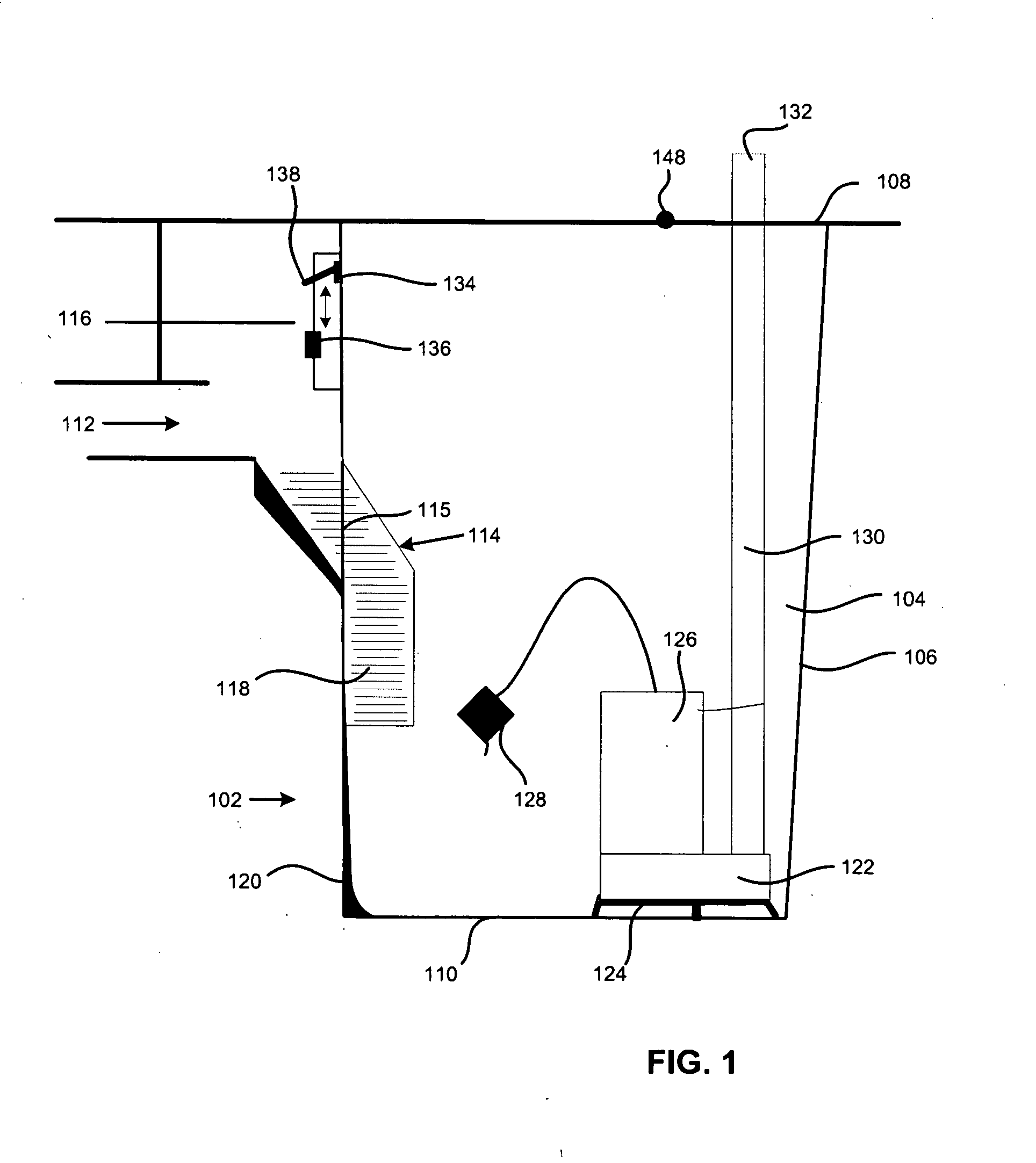

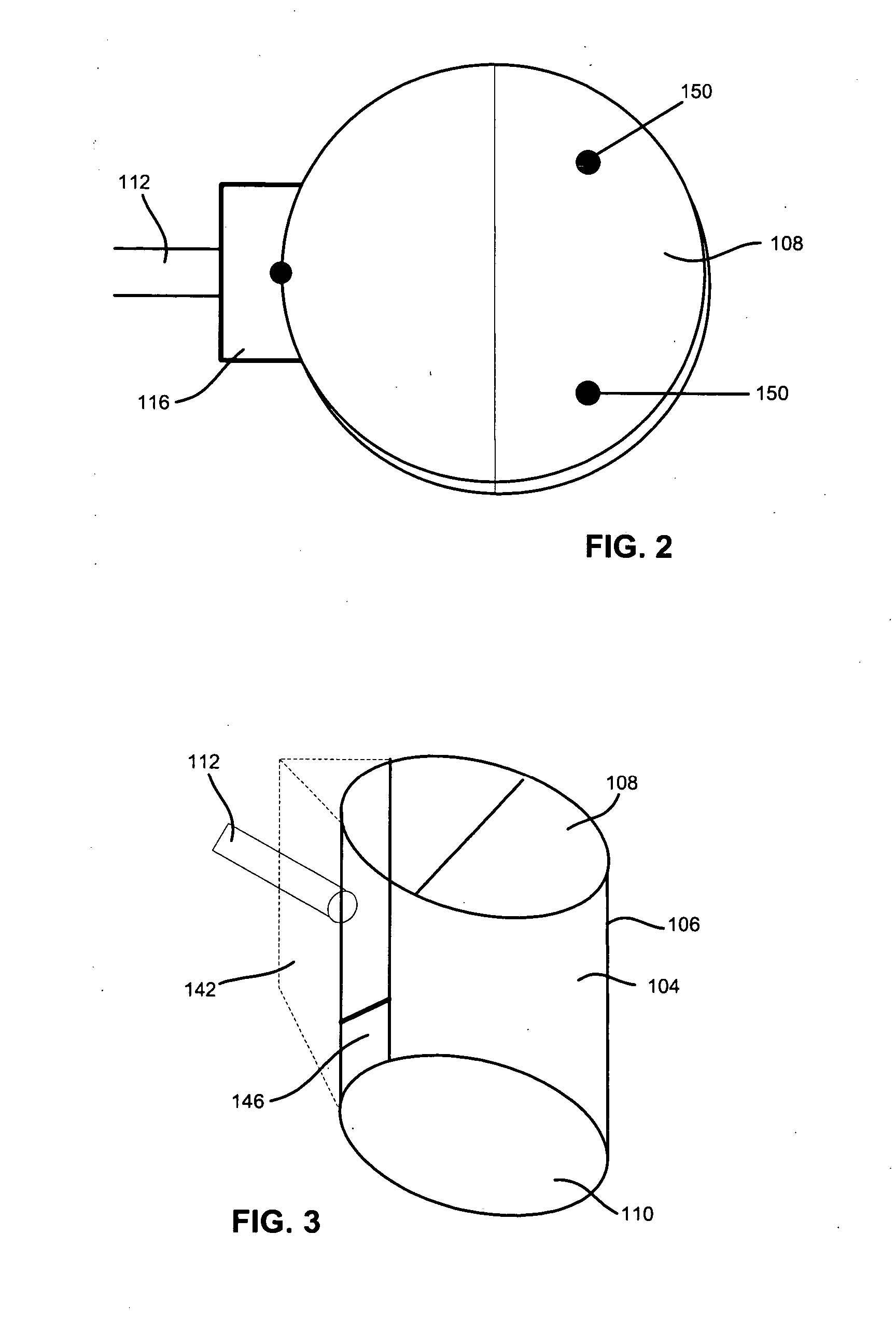

[0013] The present invention relates to a new and novel sewage lift station 102 for accumulating and conveying sewage to a remote destination.

[0014] Referring now generally to FIG. 1, an embodiment of the invention is shown which includes a substantial barrel shape sewage receptacle or housing 104. The housing 104 includes a contiguous wall 106 with a spaced apart top 108 and bottom 110. A sewer inlet pipe 112 is mounted onto the wall 106 of the sewer housing 104. A sewage drop pipe 114 is formed into the wall 106 of the housing 104 adjacent to and generally downward from the inlet pipe 112.

[0015] The sewage drop pipe 114 includes a lower portion 118 which depends generally downward from the side of the housing 104 toward the bottom surface 110 and away from the top surface 108. The sewage drop pipe 114 also includes an upper portion 116 which is oriented generally upward and adjacent the inlet pipe 112. It is preferred that the upper portion 116 of the sewage drop pipe 114 be pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com