Epoxy rock coaster

a technology of epoxy rock and rollers, applied in the field of epoxy rock rollers, can solve the problems of dripping from the pool of condensation remaining on the surface of the tray, spilling of drink, and affecting the appearance of the tray, so as to protect the delicate surface from abrasion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

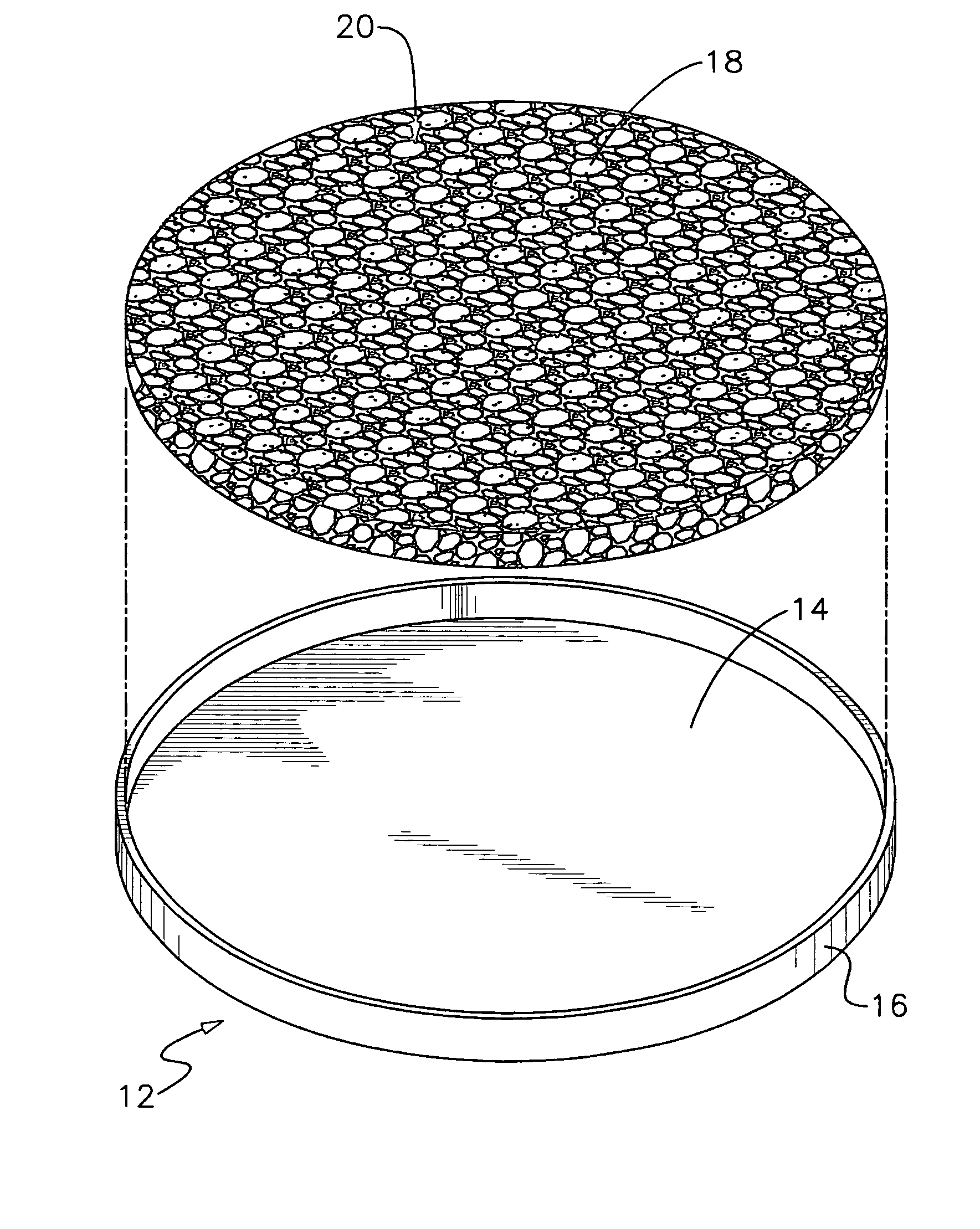

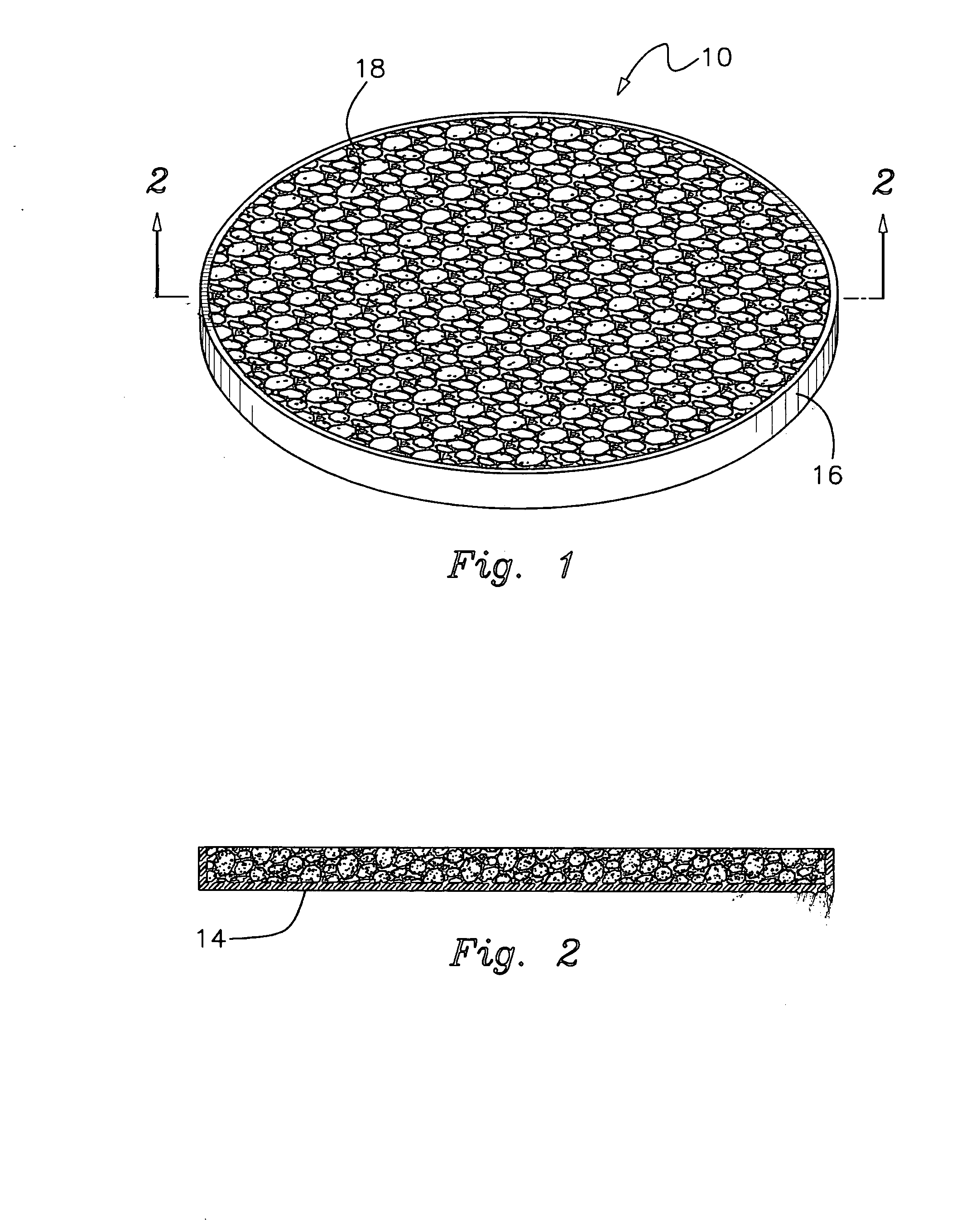

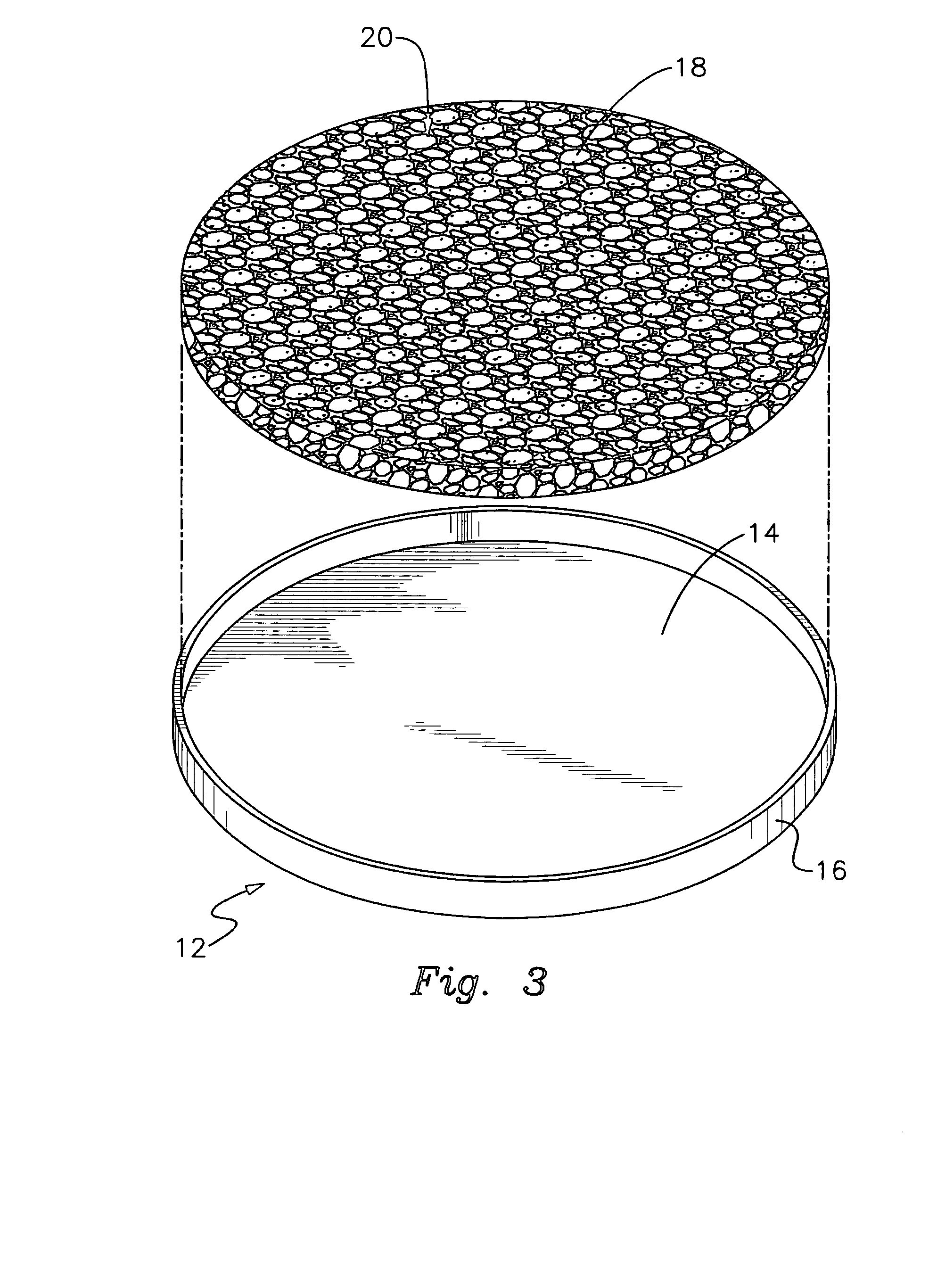

[0008] The present invention provides a porous structured solid rock coaster 10 designed to absorb and contain condensation that forms from drinking containers such as beverage bottles, glasses and metal cans. In addition, the present coasters can be scaled up in size to catch and contain excess water when placed under plant and flower pots.

[0009] The epoxy rock coaster is composed of a composition of mixed stone aggregate cured with an epoxy resin system within a plastic vessel. Referring to FIGS. 1, 2 and 3, the epoxy rock coaster 10 is illustrated. The vessel 12 is made of plastic, preferably polyethylene or other suitable plastic material. Although the vessel is shown to be round, it can be of any desired shape. Plastic vessel 12 has a flat bottom 14 and upward extending side wall 16. The exterior diameter of vessel 12 is about four inches with an effective depth of wall 16 of about 0.25 inch to 0.35 inch, preferably about 0.31 inch. The thickness of the plastic is about 0.06 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com