Low-profile impeller bolt

a technology of impeller bolts and bolt heads, which is applied in the direction of pump components, non-positive displacement fluid engines, reaction engines, etc., can solve the problems of reducing pumping efficiency, affecting the speed of pumping, and affecting the efficiency of pumping, so as to achieve the effect of limiting the distan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

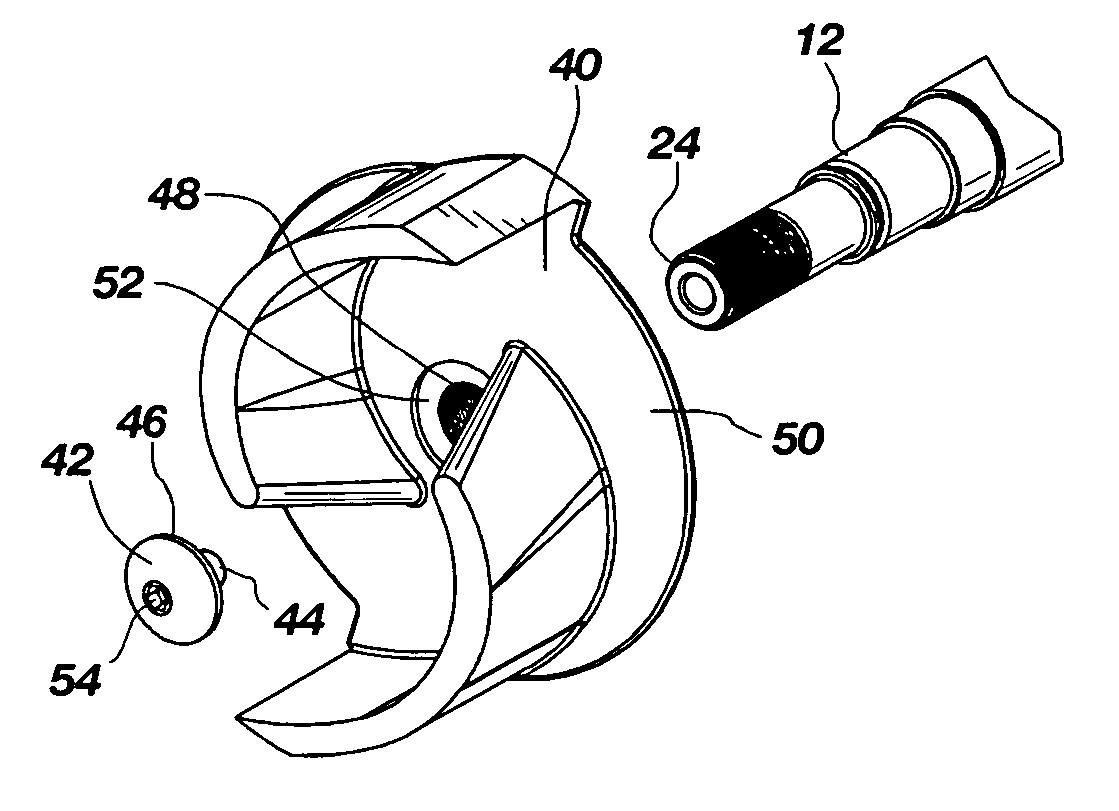

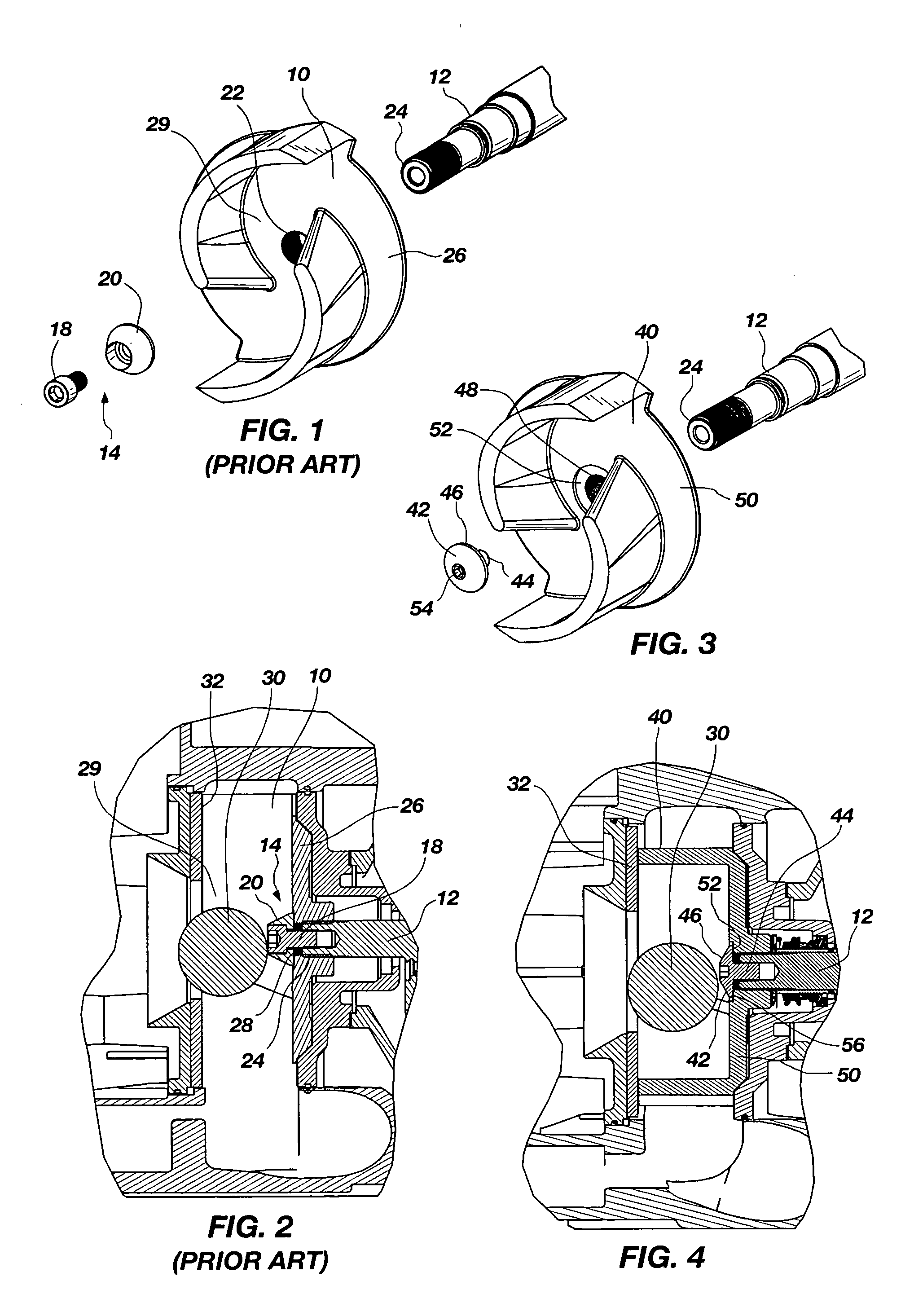

[0018] A typical impeller arrangement of the prior art is shown in FIGS. 1 and 2 as a comparative illustration of the problem solved by the present invention. In FIG. 1, which illustrates an exploded view of an impeller 10, drive shaft 12 and means 14 for attaching the impeller 10 to the drive shaft 12, the means 14 for attachment comprises a standard socket head cap screw 18 and a washer 20. As seen in FIGS. 1 and 2, the screw 18 fits through the washer 20 and through the central opening 22 in the impeller 10 to threadingly engage the terminal end 24 of the drive shaft 12.

[0019] The washer 20 typically used in prior art impeller attachment is conically-shaped. As best illustrated in FIG. 2, when the washer 20 is secured in place by the screw 18, the washer 20 is positioned against the surface of the base or shroud 26 of the impeller 10. The washer 20 consequently provides a spacer 28 between the screw 18 and the shroud 26 of the impeller 10. So configured, the screw 18 and washer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com