System and method for supplying breathing gas to a diver

a technology for providing breathing gas and diver, which is applied in the field of systems for providing breathing gas to diver, can solve the problems of affecting the flow of gas through the hose, etc., and achieves the effects of reducing wind or water resistance, reducing the amount of gas flowing through the hose, and reducing the difficulty of users moving freely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

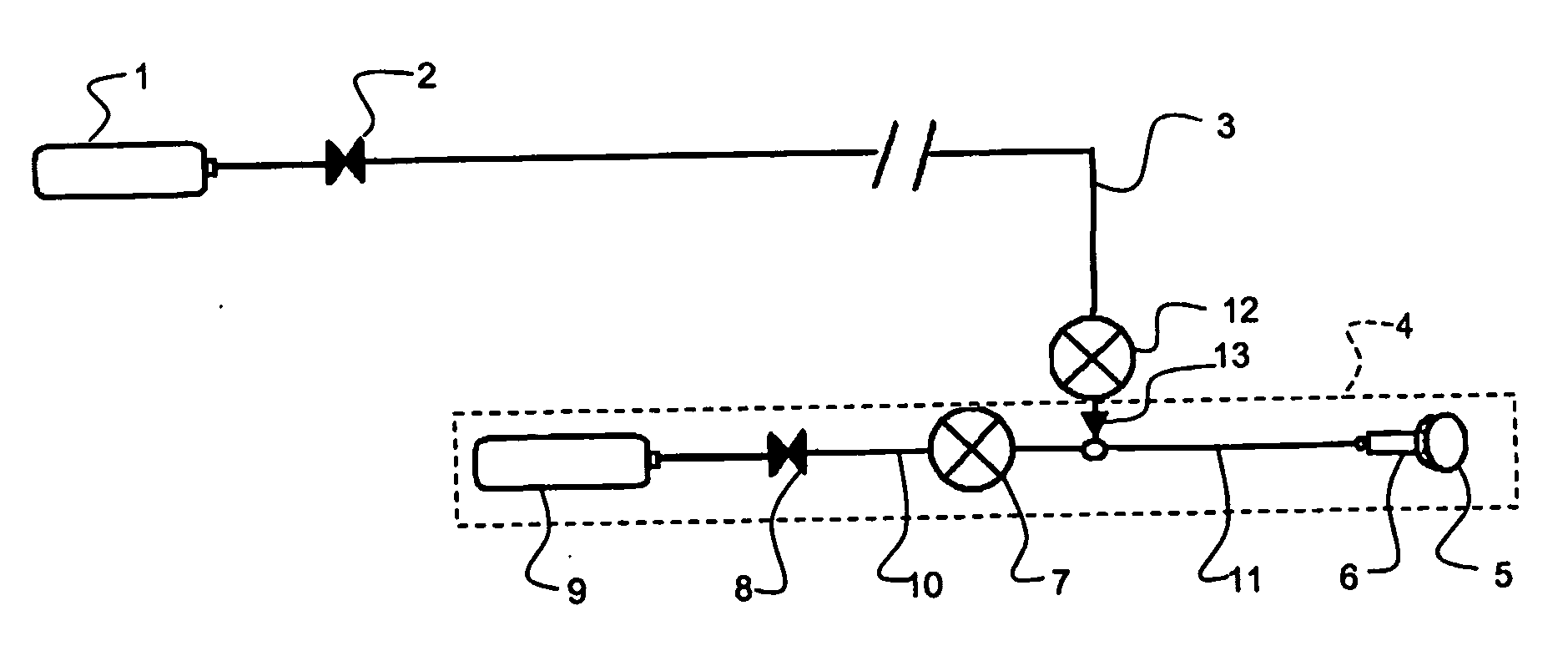

[0020]FIG. 1 shows a diagrammatic sketch of the invention, and

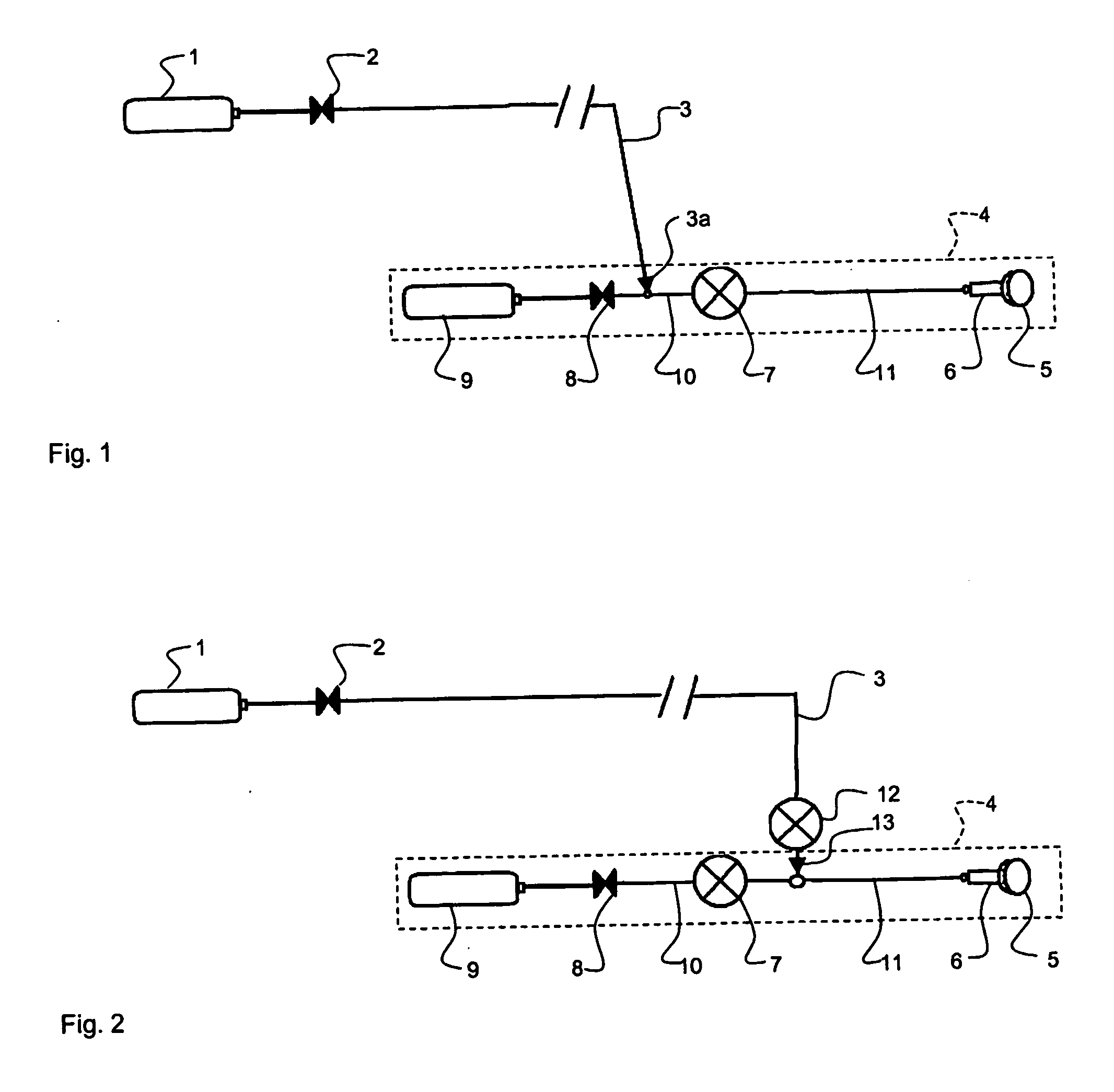

second embodiment

[0021]FIG. 2 shows a corresponding diagrammatic sketch of a

[0022]FIG. 1 shows a first embodiment of a system according to the invention. The system comprises a gas source in the form of a pressurized container 1 which contains breathing gas, for example air or nitrox. The container is of the standard type found on the market. These standard containers have different maximum pressure for different markets. The maximum pressure, which corresponds to the pressure in the container when it is full, is 200 bar on some markets, for example, while it is 300 bar on other markets. Containers with a maximum pressure of 700 bar are also found. All these different standard containers, but also other containers which deliver breathing gas under high pressure, can be used in the system according to the invention. The main point is that the container can deliver exhalation gas under a pressure which is considerably higher than the ambient pressure surrounding the diver.

[0023] The container is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com