Lundell type rotor core structure and rotary electric machine employing the same

a technology of rotor core structure and electric rotary machine, which is applied in the direction of dynamo-electric machines, magnetic circuit rotating parts, and shape/form/construction of magnetic circuits, etc., can solve problems such as magnetic sound output, and achieve the effect of suppressing magnetic sound and simplifying structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A Lundell type rotor core structure of a rotary electric machine according to the present invention is described below in detail with reference to the accompanying drawings. However, the present invention is construed not to be limited to the embodiment described below and a technical concept of the present invention may be implemented in combination with other known technologies or the other technology having functions equivalent to such known technologies.

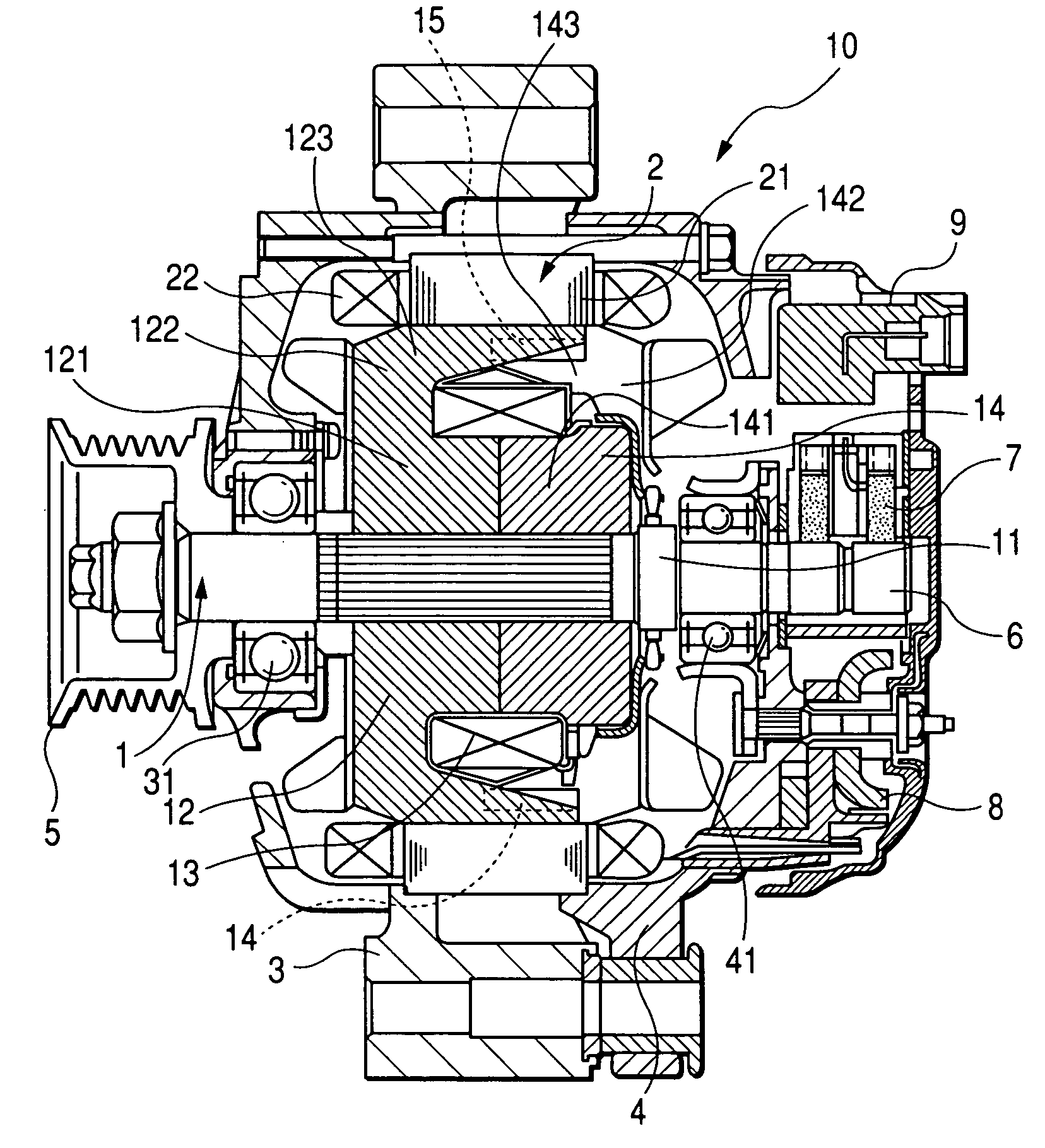

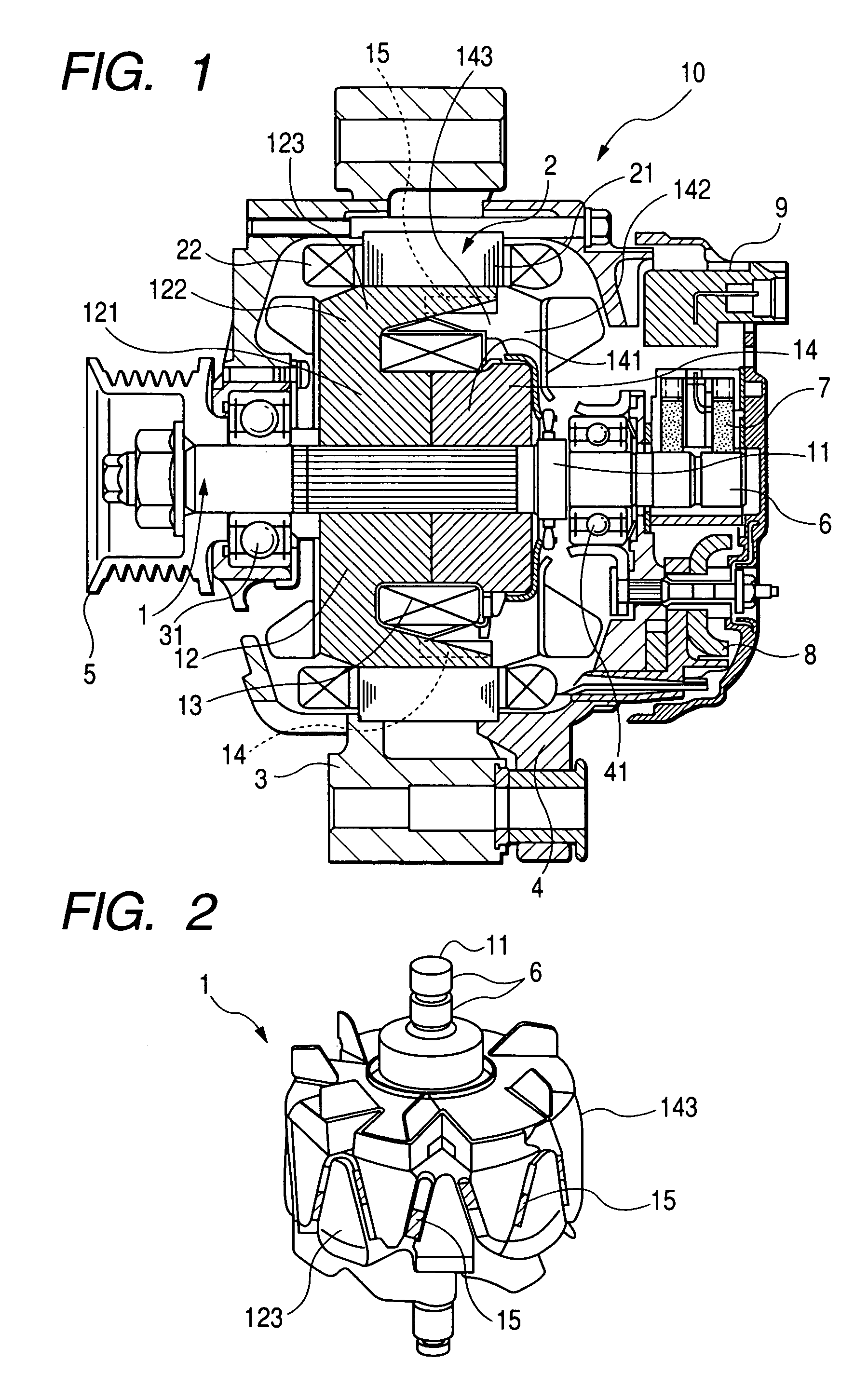

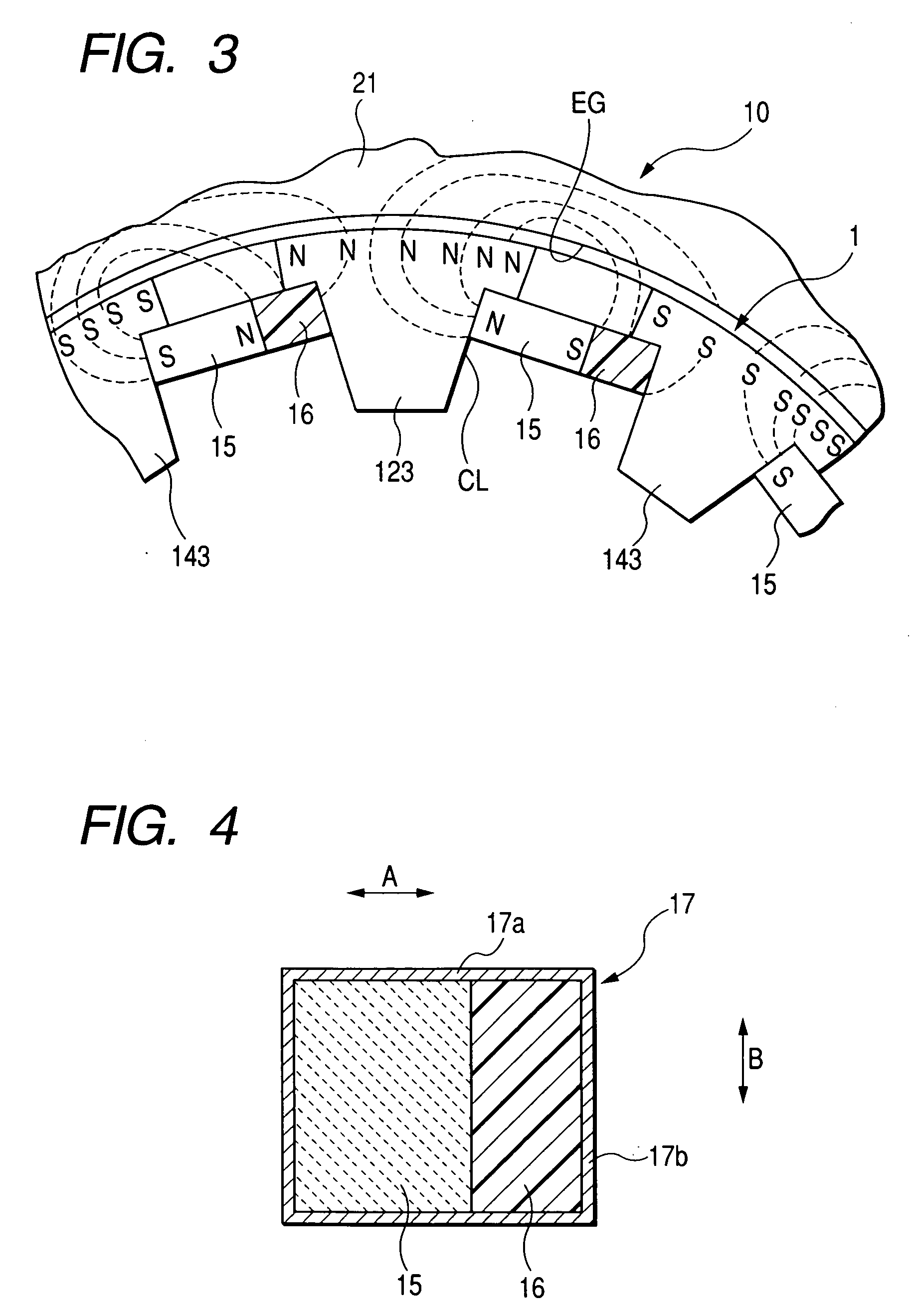

[0035]FIG. 1 shows a vehicle alternator, playing a role as an electric rotary machine, which has a Lundell-type rotor core structure of a first example according to the present invention. FIG. 2 is a perspective view of the rotor core structure incorporated in the vehicle alternator shown in FIG. 1 and FIG. 3 is an enlarged partial view showing the relationship between permanent magnets and associated claw pole portions of the rotor core structure shown in FIG. 2.

[0036] As shown in FIG. 1, the vehicle alternator 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com