Methods of treating deposition process components to form particle traps, and deposition process components having particle traps thereon

a technology of deposition process components and particle traps, which is applied in the direction of vacuum evaporation coatings, chemistry apparatuses and processes, coatings, etc., can solve the problems of affecting the desired properties of films, and affecting the adhesion of film surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

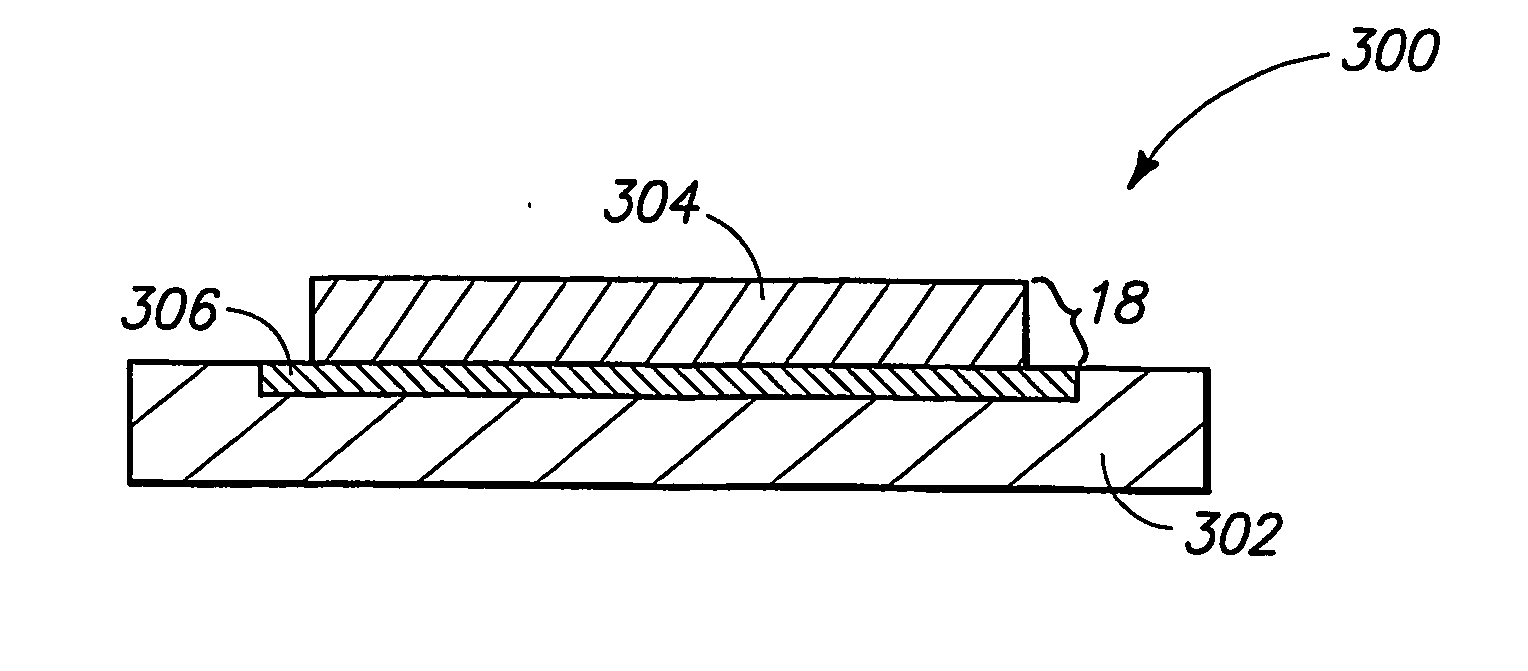

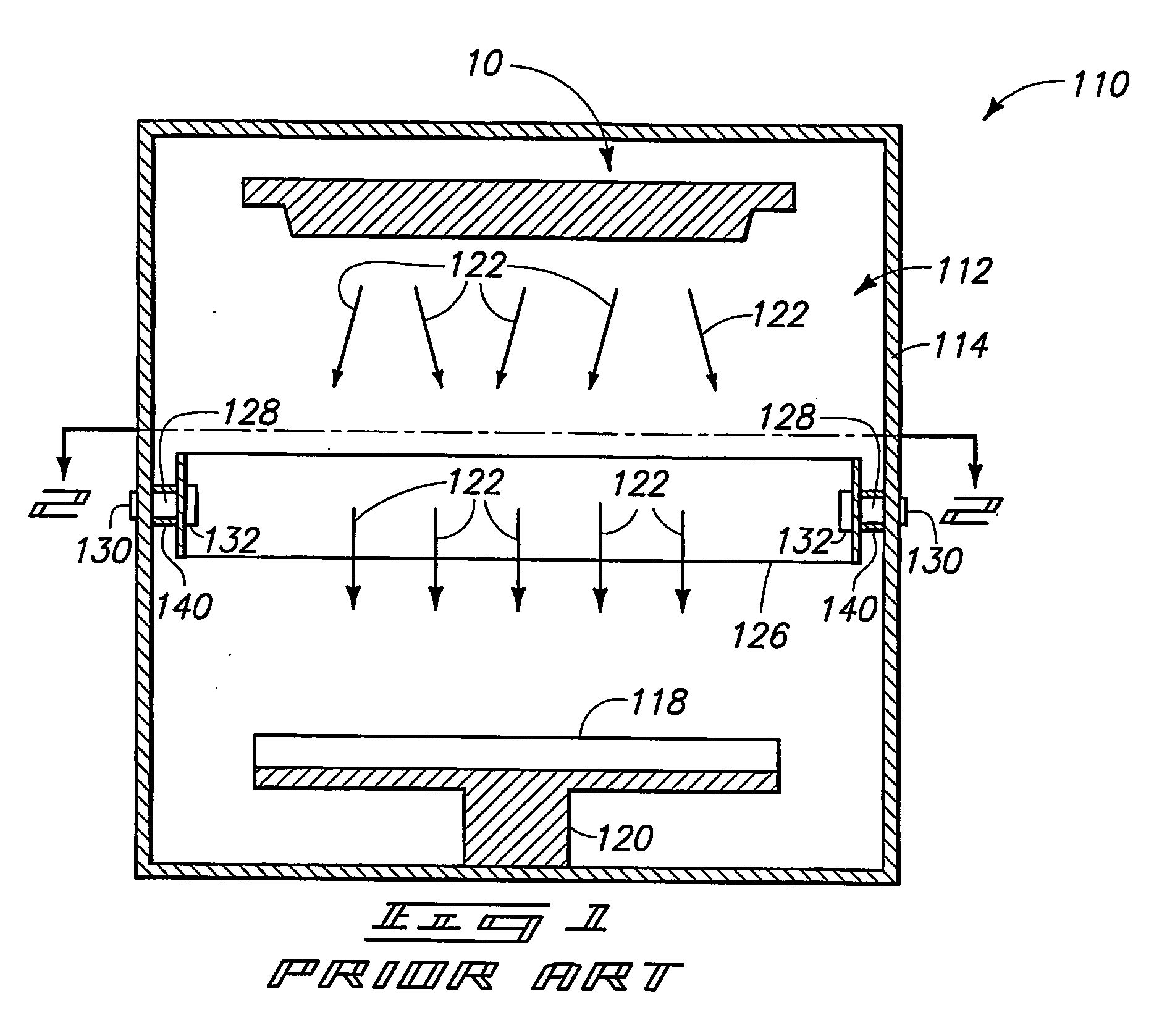

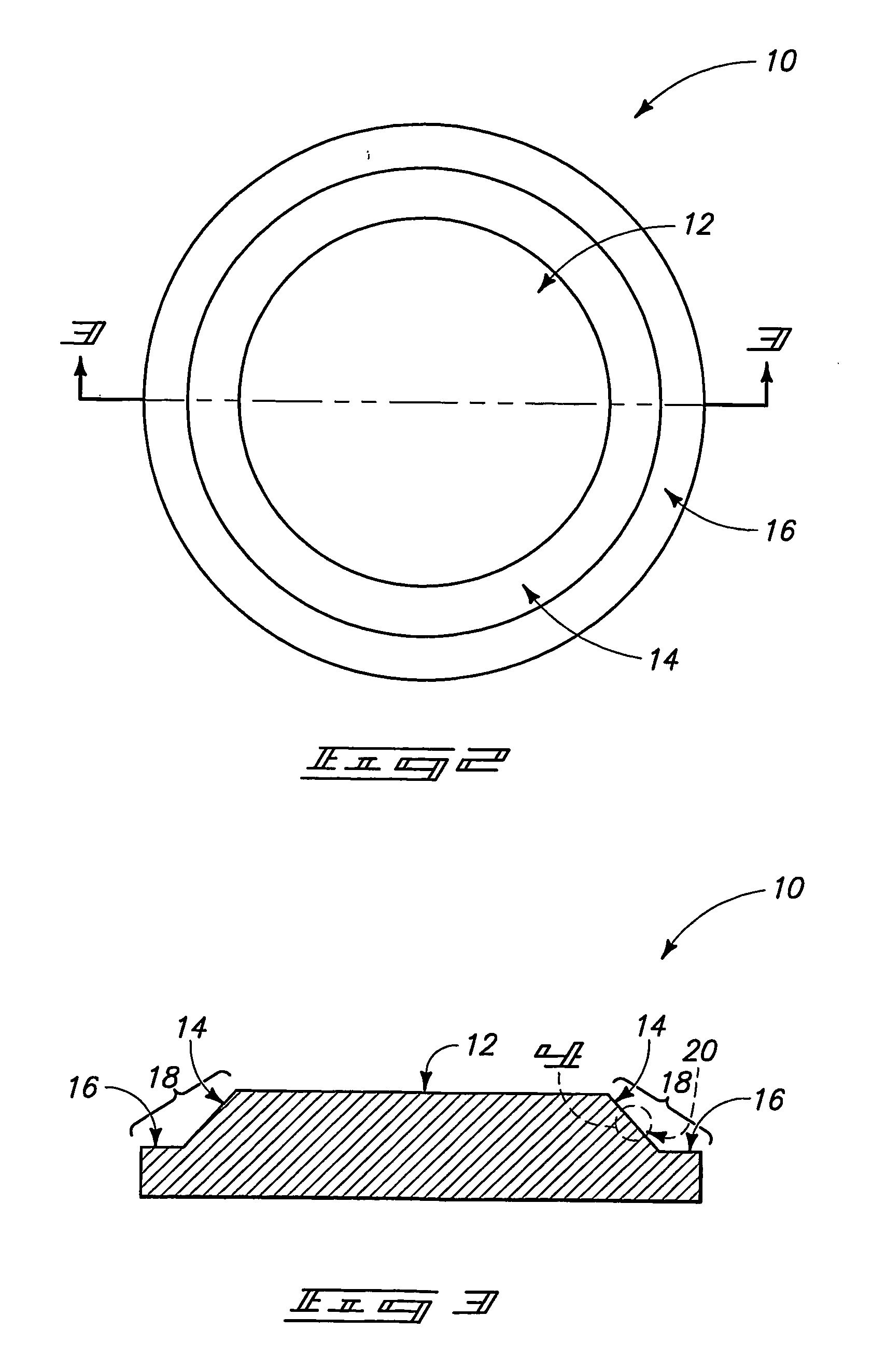

[0031] The invention encompasses particle-trapping regions which can be formed on one or more surfaces of a PVD component, and methods of forming the particle-trapping regions. The particle-trapping regions can be utilized for trapping materials which deposit on the component during a deposition process.

[0032] The particle-trapping regions are formed by treating one or more surfaces of the PVD component with bead blasting, and in some aspects also with machine tooling. If the treated component is a sputtering target, the treated surfaces can include any non-sputtered surfaces, such as, for example, sidewall surfaces, flange surfaces and / or non-sputtered surfaces along a sputtering face.

[0033] Projections formed with machine tooling can be considered to correspond to a macro-scale roughness, and roughening accomplished by bead blasting can be considered to correspond to a micro-scale roughness. Thus, the invention can include patterns which have one or both of macro-scale and micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| repeat distance | aaaaa | aaaaa |

| repeat distance | aaaaa | aaaaa |

| repeat distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com