Compact fluorescent lamp and method for manufacturing

a fluorescent lamp and compact technology, applied in the manufacture of electrode systems, cold cathode manufacturing, electric discharge tube/lamp manufacture, etc., can solve the problems of large length dimension, low manufacturing efficiency, and low efficiency of fluorescent lamps, so as to improve the resistance to mechanical vibration and simplify the sequential manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

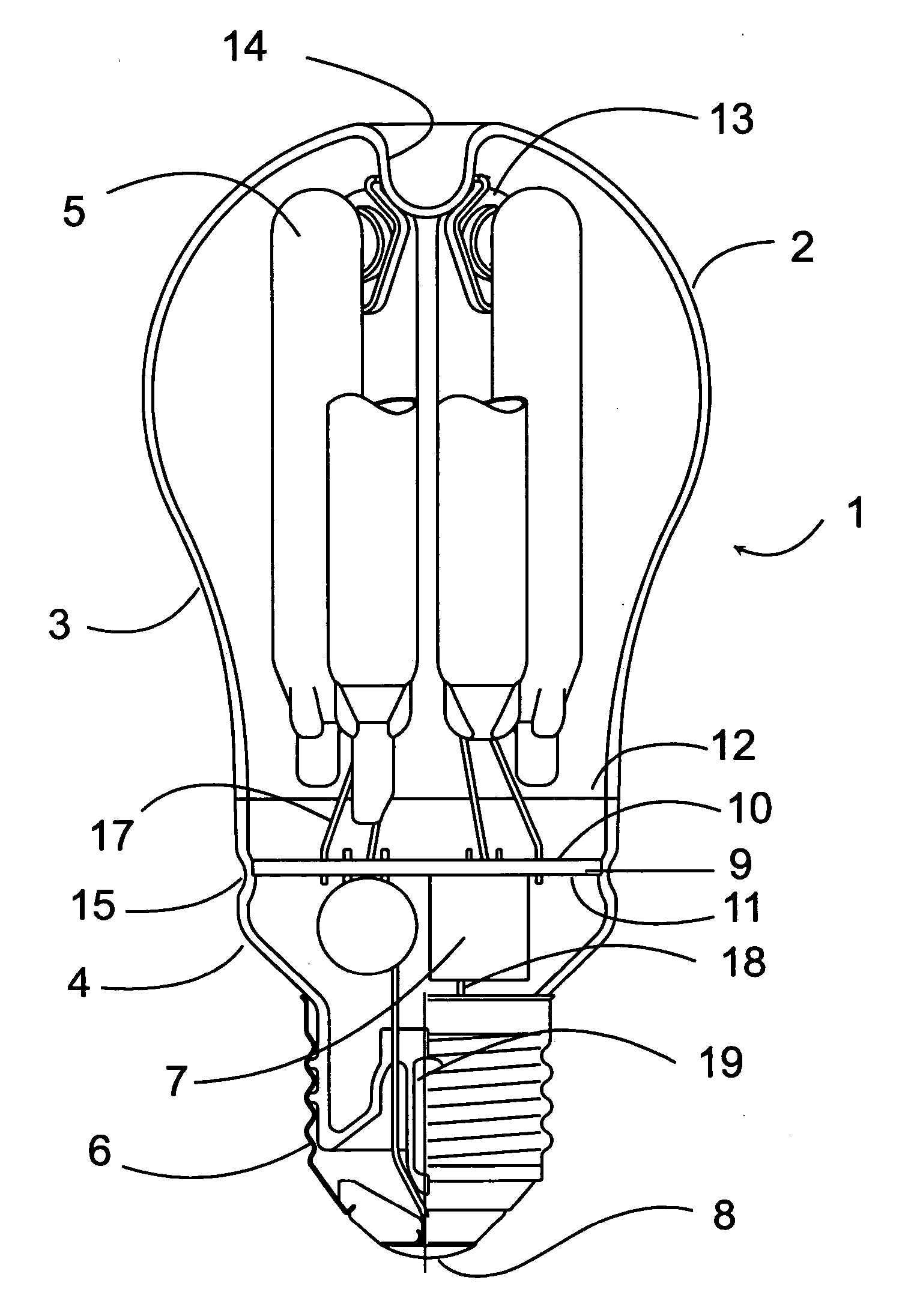

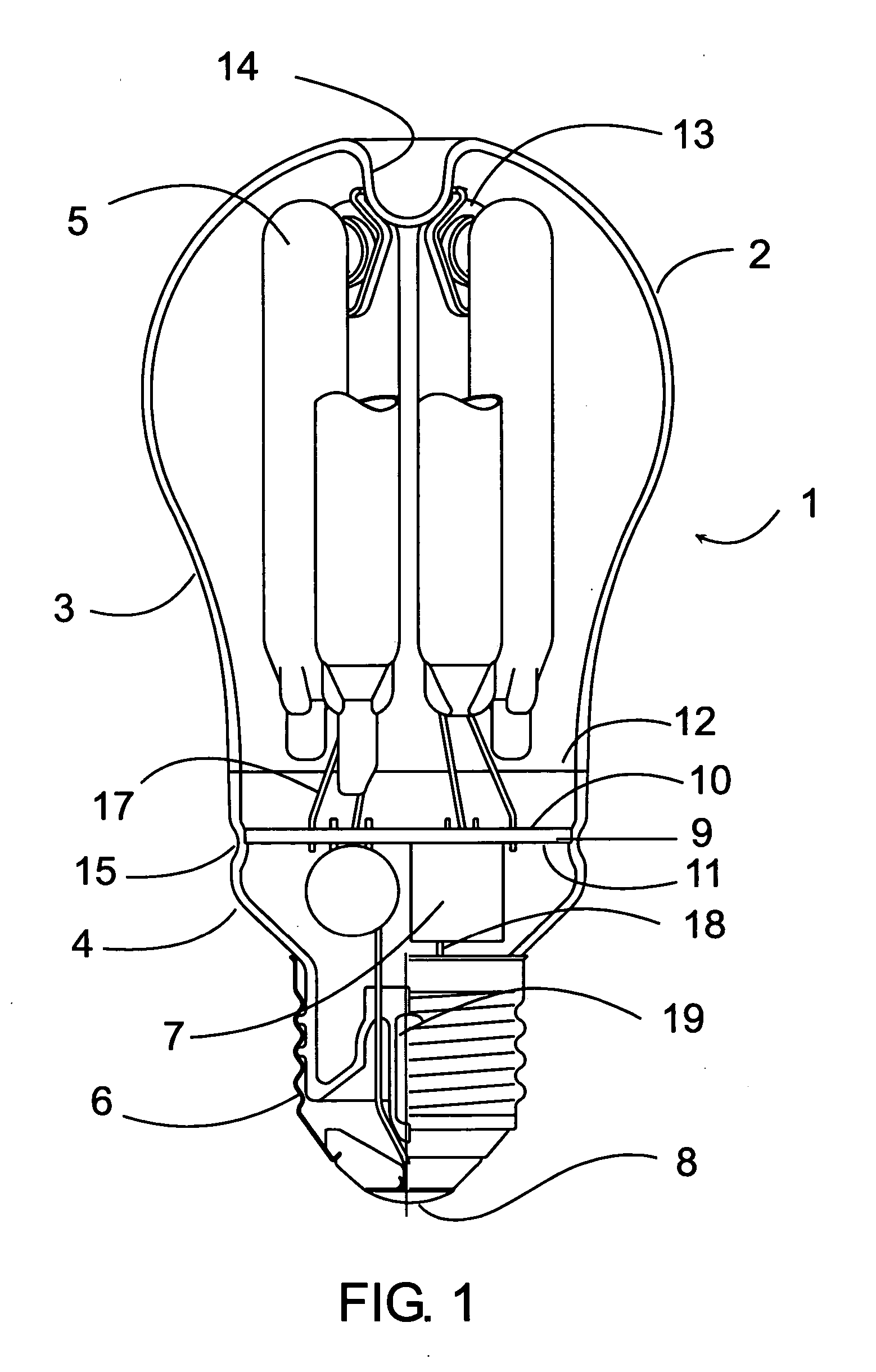

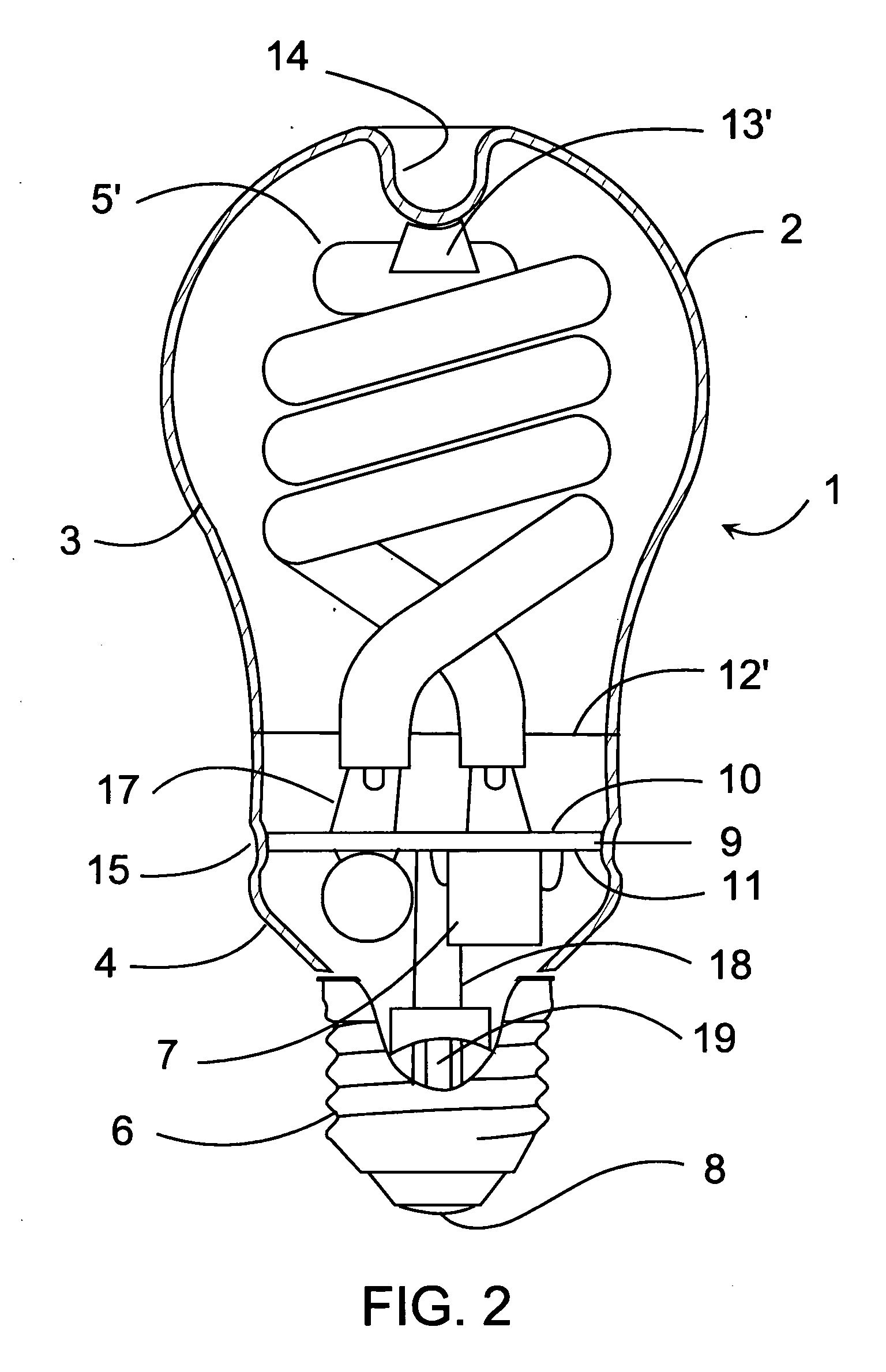

[0021] Referring now to FIG. 1, a low-pressure discharge lamp I is shown. The lamp is a fluorescent discharge lamp, with an outer envelope 2 enclosing a discharge tube arrangement 5 and a ballast circuit 7. The outer envelope 2 may be transparent or translucent, and may be made of glass. The outer envelope 2 has a substantially spherical portion and an elongated end portion. The outer envelope 2 is hermetically sealed at its elongated end portion and connected to a base 6. The outer envelope is cut in two parts and separated at cutting line 12 in order that the ballast circuit 7 and the discharge tube arrangement 5 can be inserted and connected inside the outer envelope 2 as described in detail below. The discharge tube arrangement 5 comprises a plurality of elongated discharge tubes. The discharge tubes are made of glass, and enclose a discharge volume filled with a discharge gas, and have a fluorescent phosphor coating disposed on the inner surface of the tubes. The ends of the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com