Waste energy recovery method and waste energy recovery system

a waste heat energy recovery and waste heat energy technology, applied in the direction of machines/engines, mechanical equipment, sustainable manufacturing/processing, etc., can solve the problems of reducing the viscosity of waste heat, poor energy use efficiency, damage to hydraulic equipment, etc., to recover waste heat energy, improve the energy use efficiency of the engine, and recover waste heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

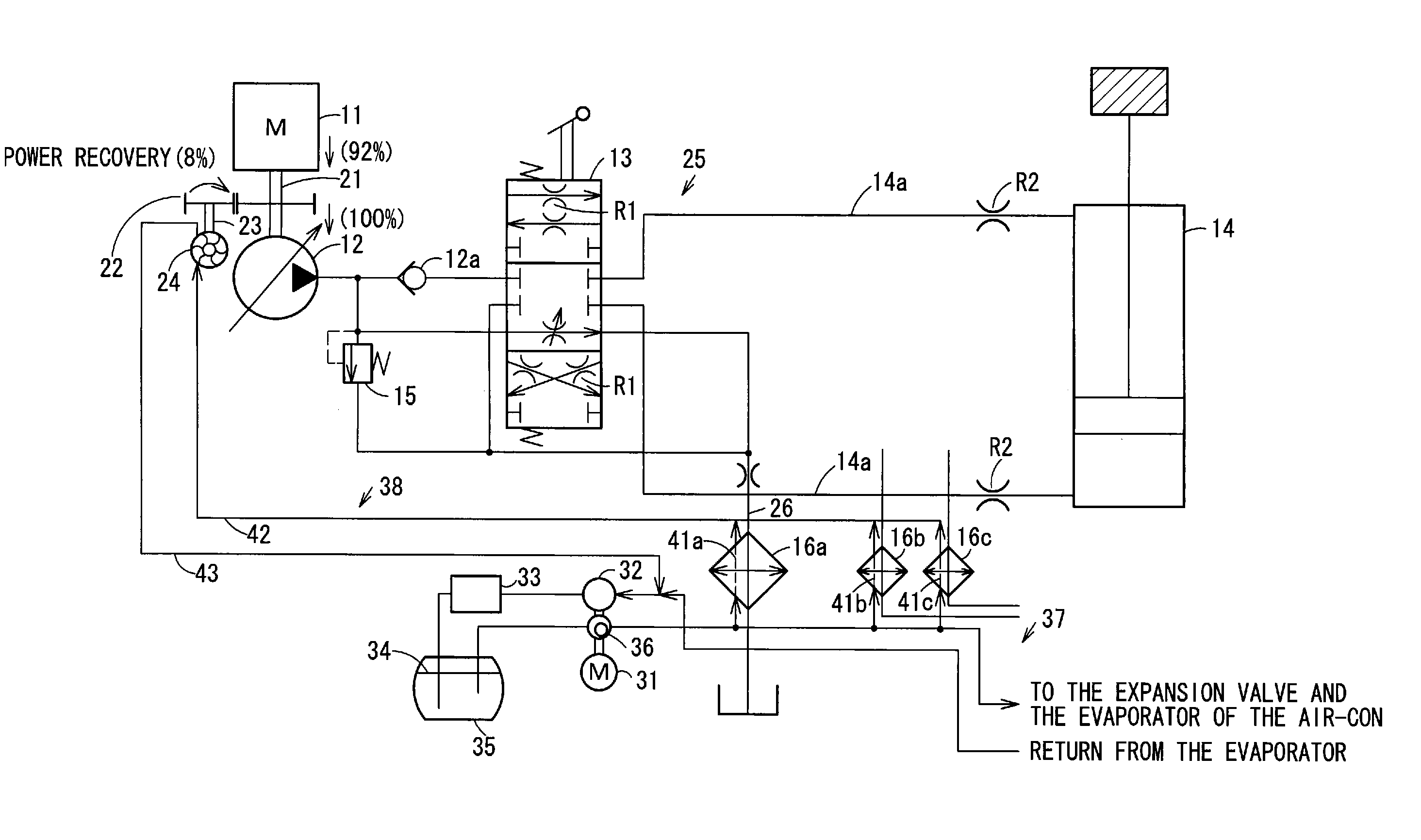

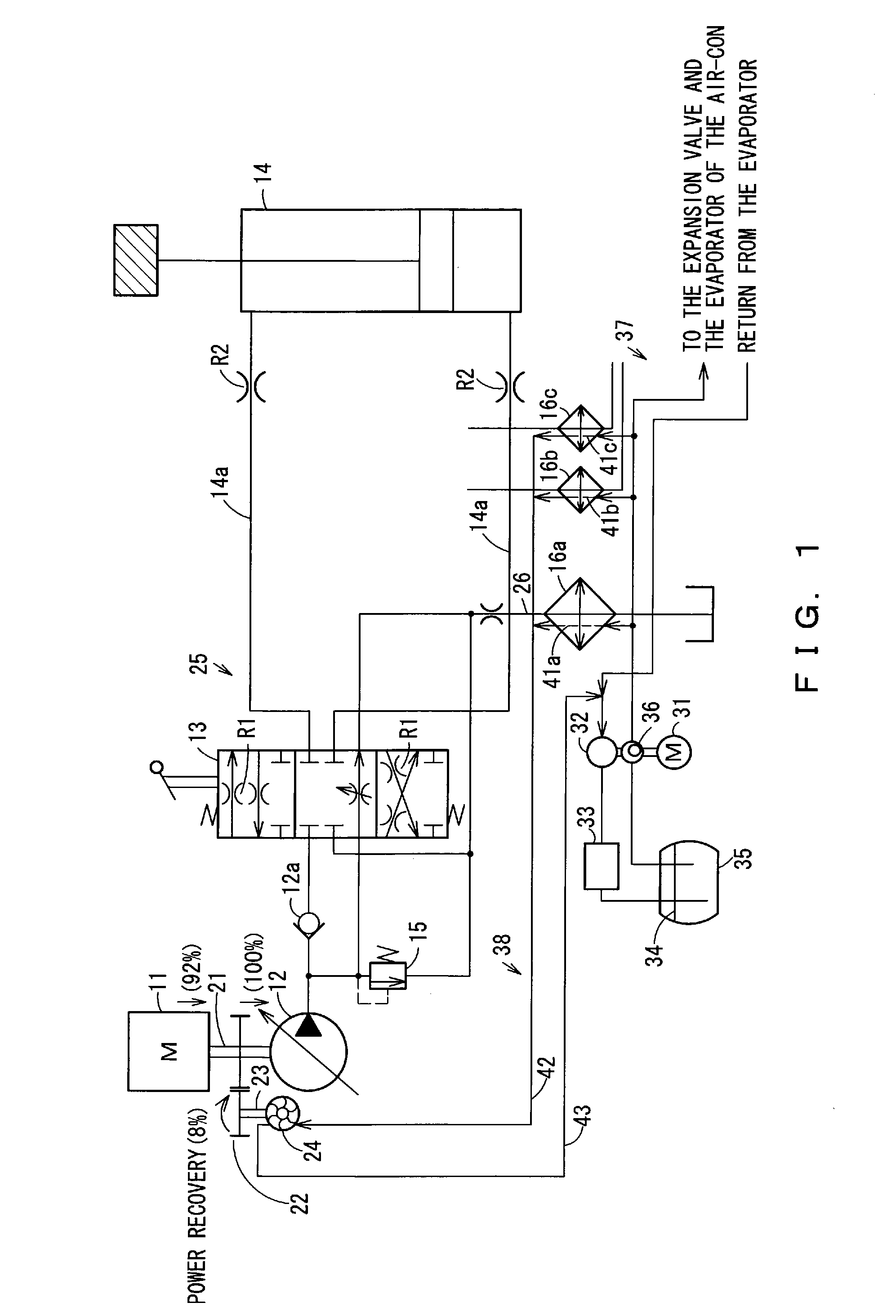

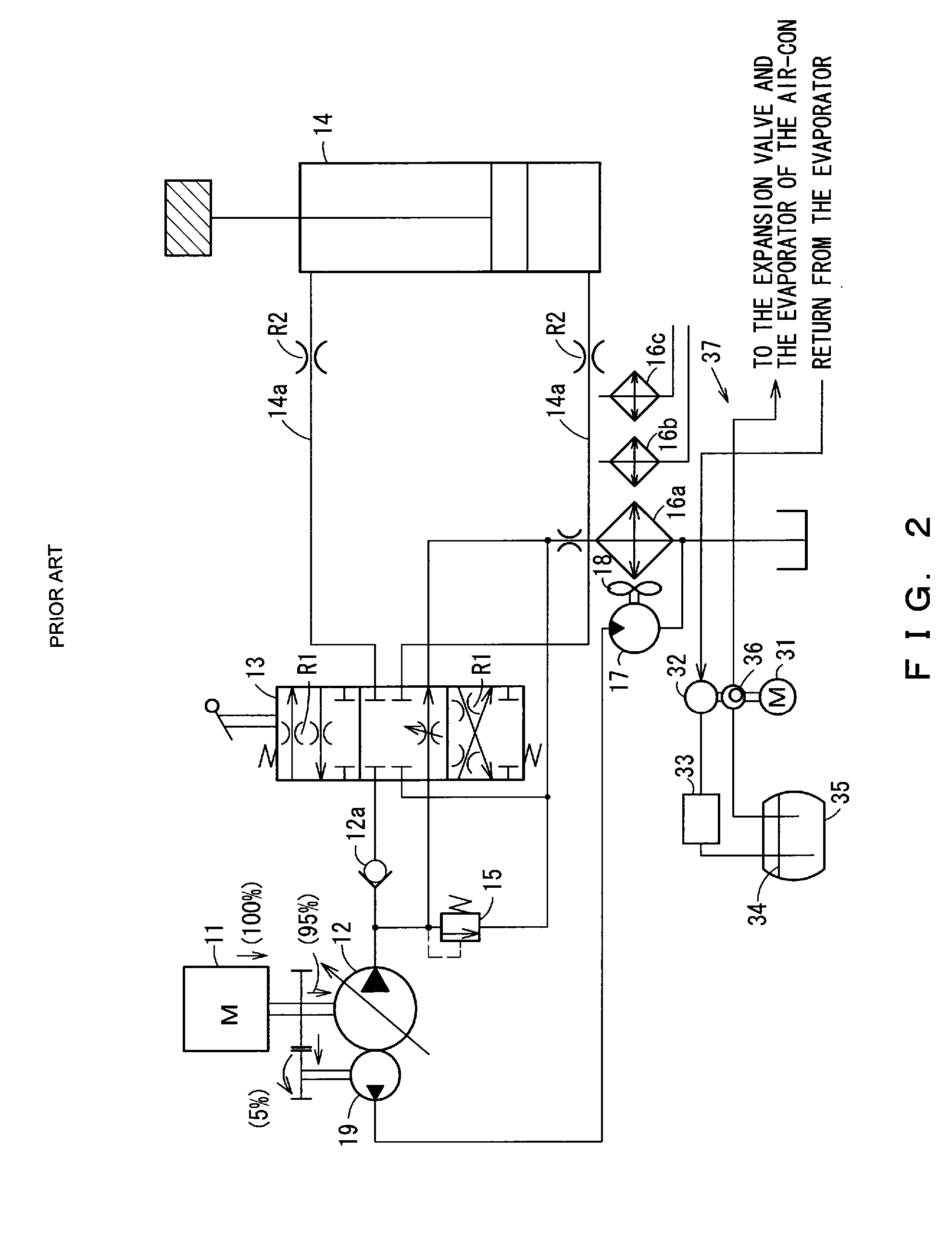

[0033] The present invention is explained hereunder, referring to FIG. 1. The elements similar to those of the conventional art shown in FIG. 2 are identified with the same reference codes, and their explanation is omitted hereunder.

[0034] As shown in FIG. 1, a diesel engine (hereinafter simply referred to as engine) 11 is mounted on a construction machine, such as a hydraulic excavator. The engine 11 is adapted to drive a pump, i.e. main pump 12, through a driving shaft unit 21 and an engine gear unit 22 that branches off from the driving shaft unit 21. The driving shaft unit 21 serves as a power transmission unit, and the engine gear unit 22 serves as a power transmission system. In place of a conventional hydraulic cooling pump 19, a steam turbine (hereinafter simply referred to as turbine) 24 is provided for the engine 11. The turbine 24 is a small power recovery turbine adapted to be rotated by means of energy provided by vaporized low-boiling medium (what is widely known as r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com