Single-material package for containing fruit and vegetable produce with lid

a single-material package and fruit and vegetable technology, applied in the box field, can solve the problems of low structural rigidity, major drop in structural rigidity, and more expensive final product, and achieve the effect of facilitating perfect vertical stacking and greater stability in stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

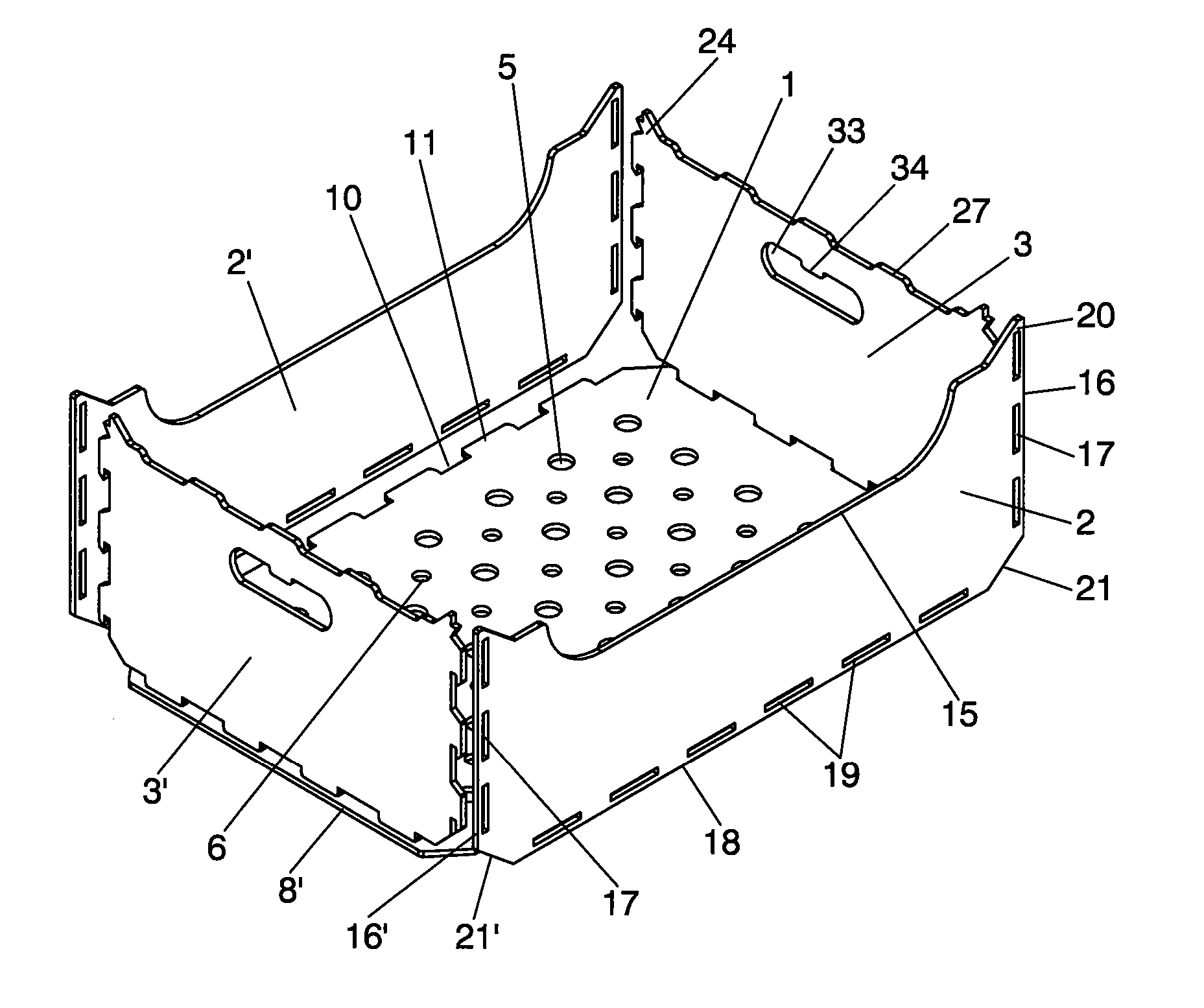

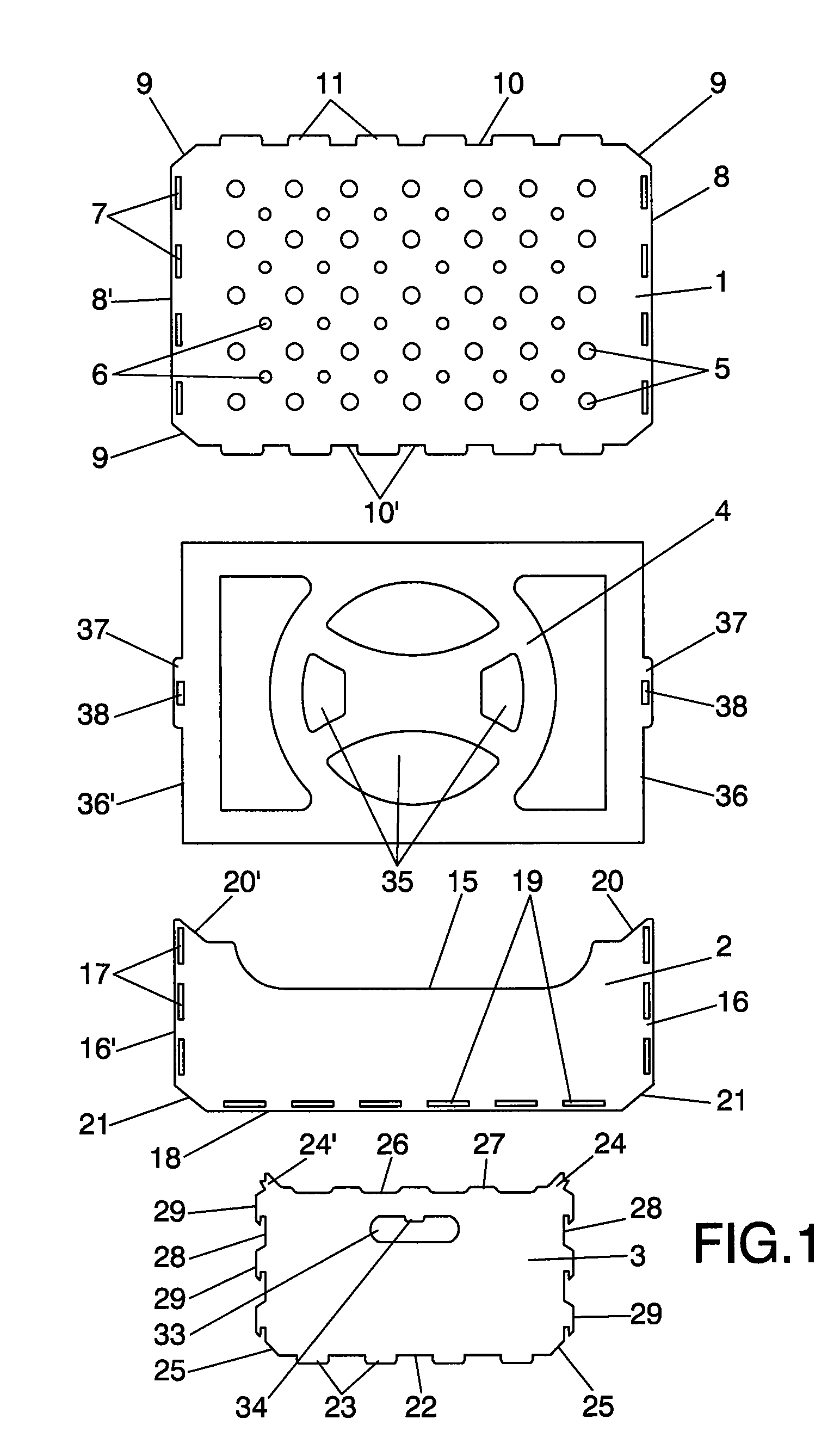

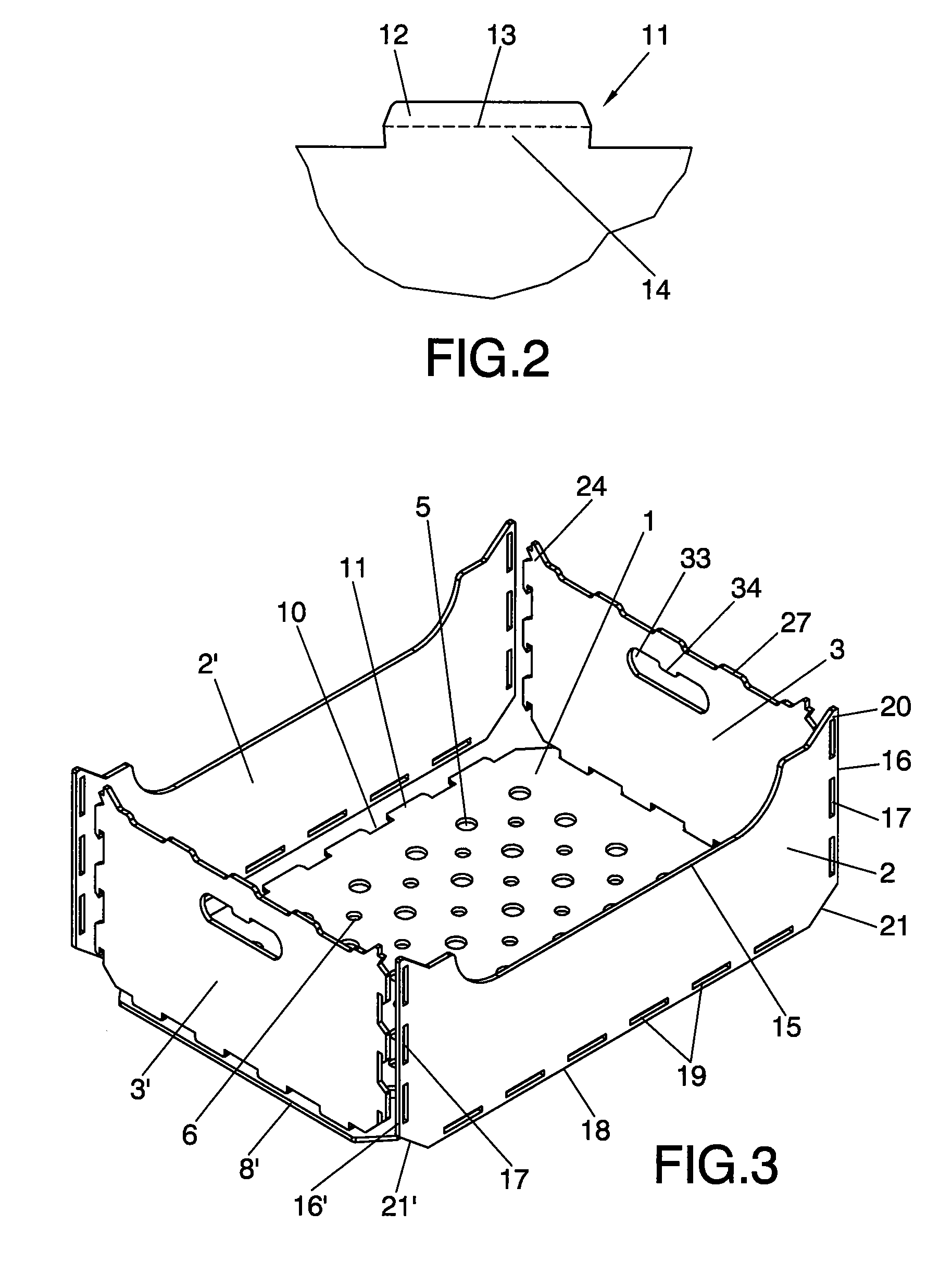

[0028] In view of the figures referred to, and particularly FIG. 1, it can be seen how the box for fruit and vegetable produce proposed by the invention consists basically of a bottom (1), two sides (2) (2′), two ends (3), (3′) and a lid (4), all being able to be coupled together.

[0029] The bottom (1) consists of a basically rectangular body, fitted with a plurality of circular holes (5) and (6), of greater and small diameter respectively, spaced out over its surface area, as well as a series of slots, (7), longitudinally distributed along its lower edges (8), (8) for tongue and groove coupling to the ends (3), (3′). The bottom (1) also has four chamfered corners (9) and a plurality of tabs (11) emerge from its larger sides (10), (10′) for tongue and groove coupling to the sides (2), (2′), in a coupling arrangement which will be explained below.

[0030] These tabs (11) have a trapezium shape with a chamfered presentation zone (12) with its edges rounded off, this zone helping to pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com