Methods for processing multifunctional, radiation tolerant nanotube-polymer structure composites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

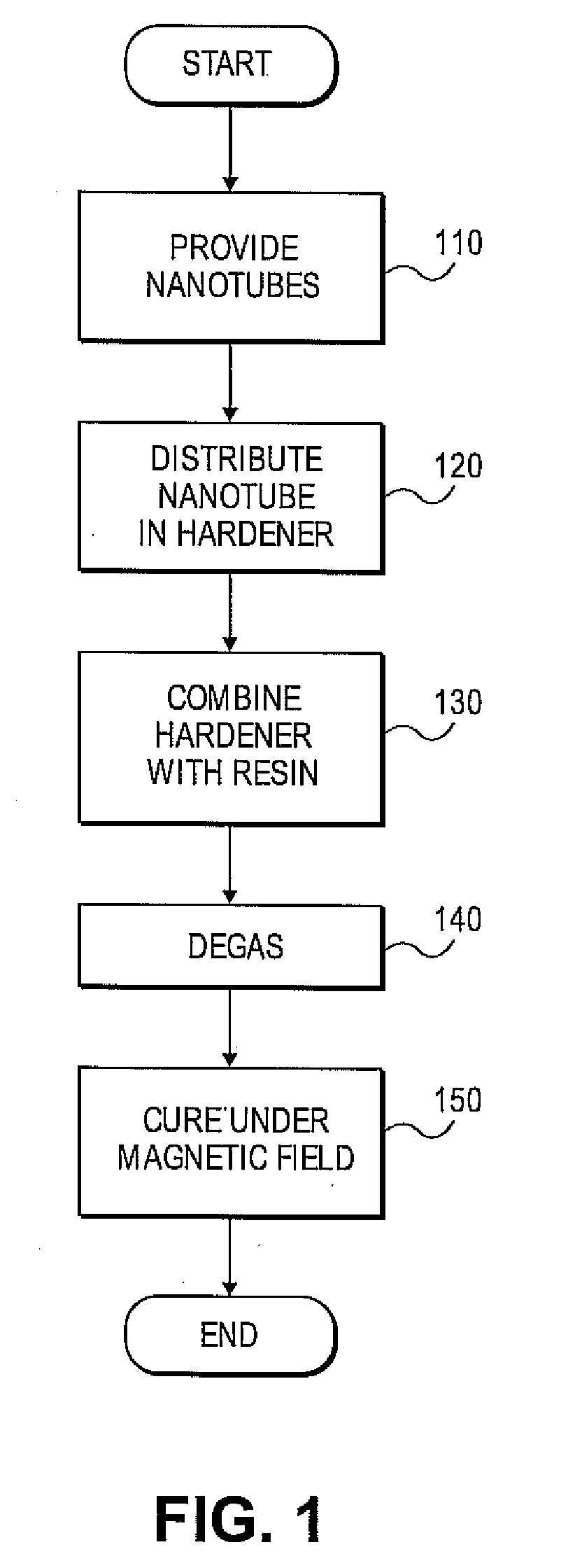

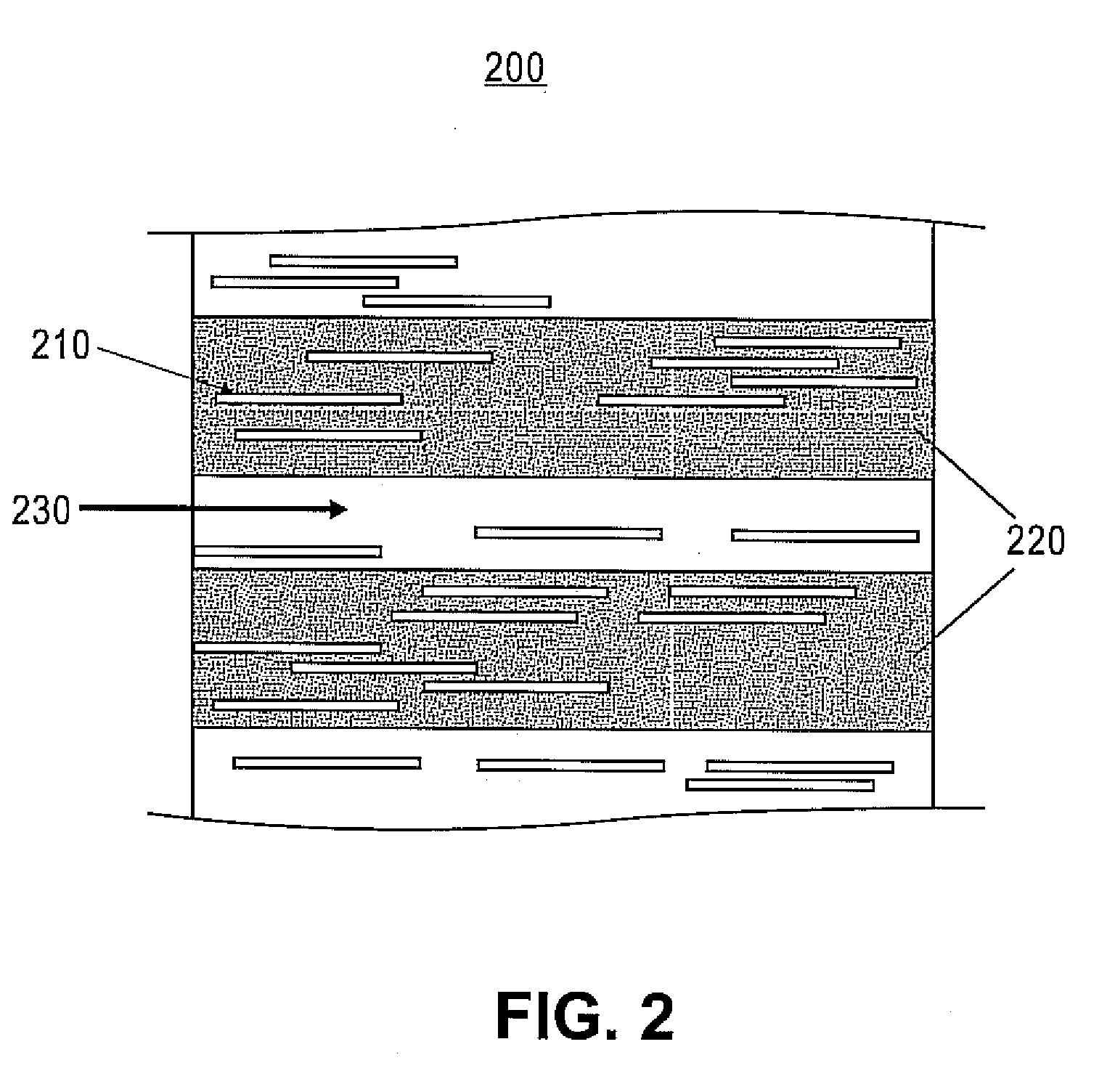

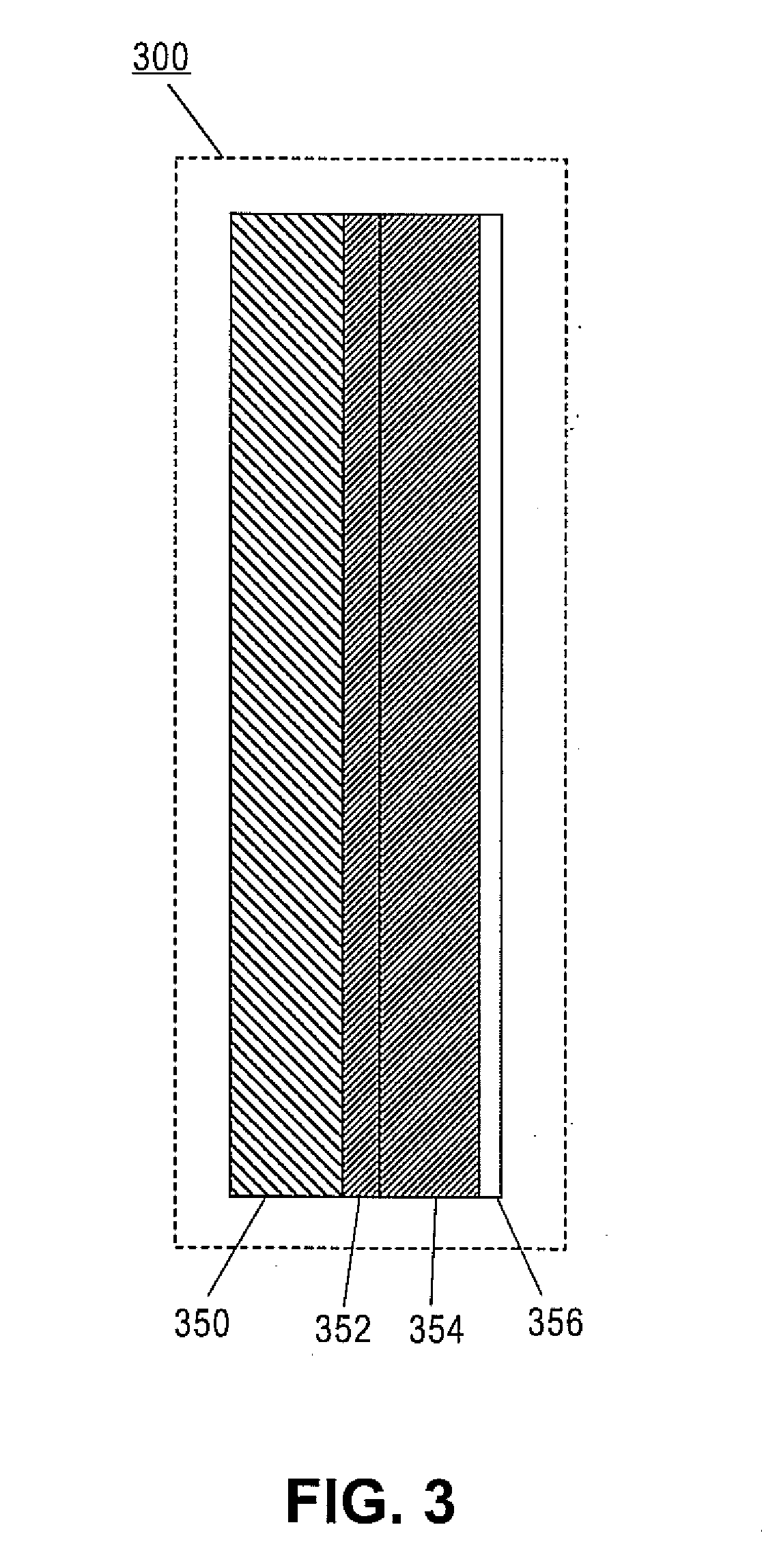

[0016] Embodiments provide a composite material including oriented nanotubes and a method for making the composite material. The composite material may be formed by distributing a plurality of nanotubes in a polymer matrix. The nanotubes may be further magnetically oriented during curing of the polymeric matrix. The composite material may provide enhanced mechanical and electrical properties, and effective radiation resistance against high-energy ionizing radiation particles and / or electromagnetic interferences. The composite material can be useful for many applications including, but not limited to, armors for vehicles, aircrafts and personnel protection, with high ballistic properties, and efficient dissipation of radiation energies, photovoltaic devices with improved polymer solar cell efficiency, improved LEDs with controllable optical properties, and infrared screening devices with increased extinction coefficient.

[0017] Reference will now be made in detail to exemplary embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com