Process to produce nonwoven fabrics with totally or partially hydrophilic areas and hydrophobic areas

a technology of hydrophilic areas and nonwoven fabrics, applied in the field of nonwoven fabrics, can solve the problems of high handling and treatment costs, energy consumption, and the inability to store and reuse solutions, and achieve the effect of producing hydrophilic characteristics, greater uniformity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

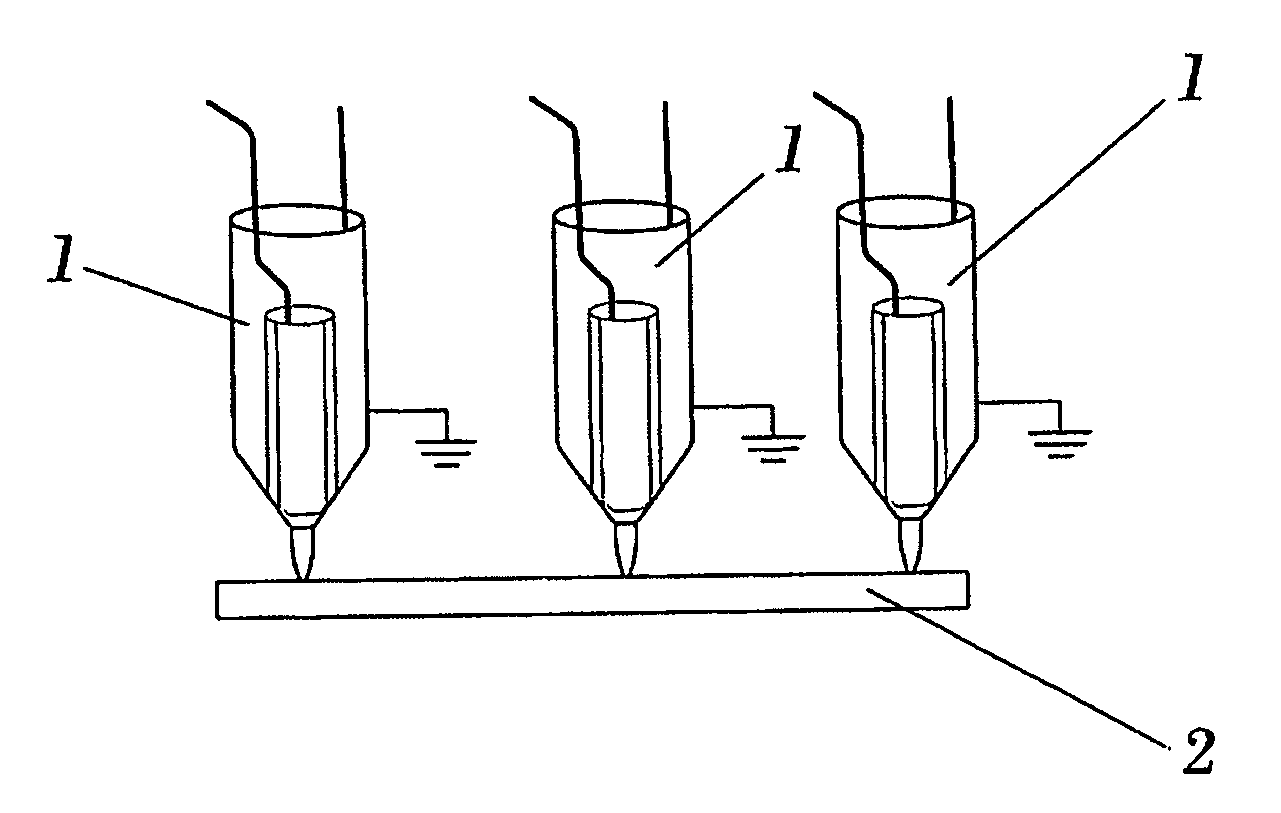

[0060] In a first embodiment, the plasma is projected from several individual heads, each one of which projects in a certain area, defining a certain geometry on the nonwoven fabric. These heads have an on / off-type frequency controller and enable partially hydrophilic areas to be produced.

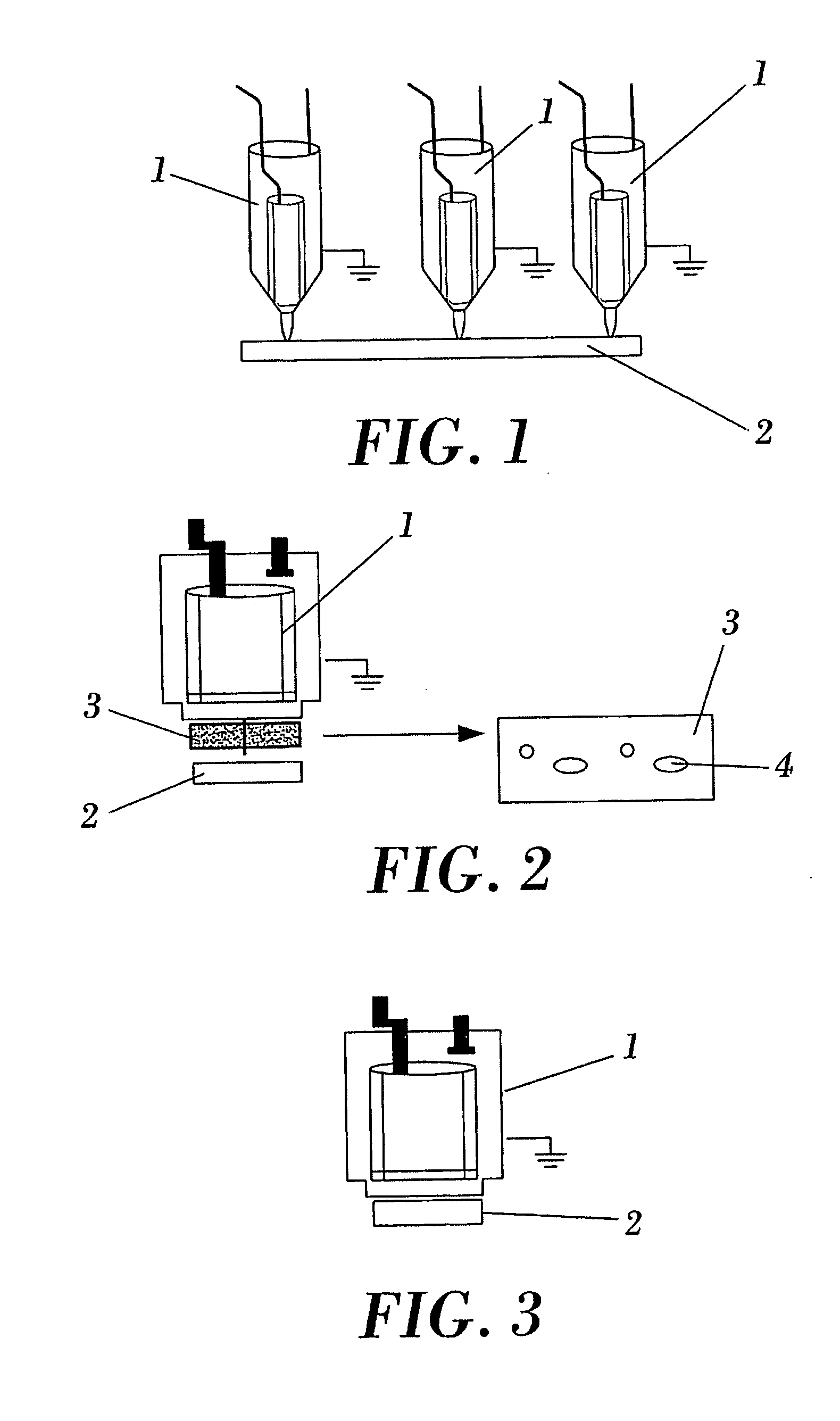

second embodiment

[0061] In a second embodiment the plasma is projected from a single head positioned across the nonwoven fabric and, between said head and the substrate to treat, there is a sheet of stainless steel, aluminum or another material provided with holes. Said holes can have varied geometries and can be distributed on the surface of the sheet in very different ways, so that the nonwoven fabric produced will have hydrophilic areas with a geometry defined by the projection of plasma through the holes in the sheet.

third embodiment

[0062] A third embodiment comprises a single head positioned throughout the fabric and incorporates software that permits defining the number of plasma pulsations per time unit. This permits the intermittent application of plasma on the nonwoven fabric which will be displaced under the head producing previously defined hydrophilic and hydrophobic areas in the end product.

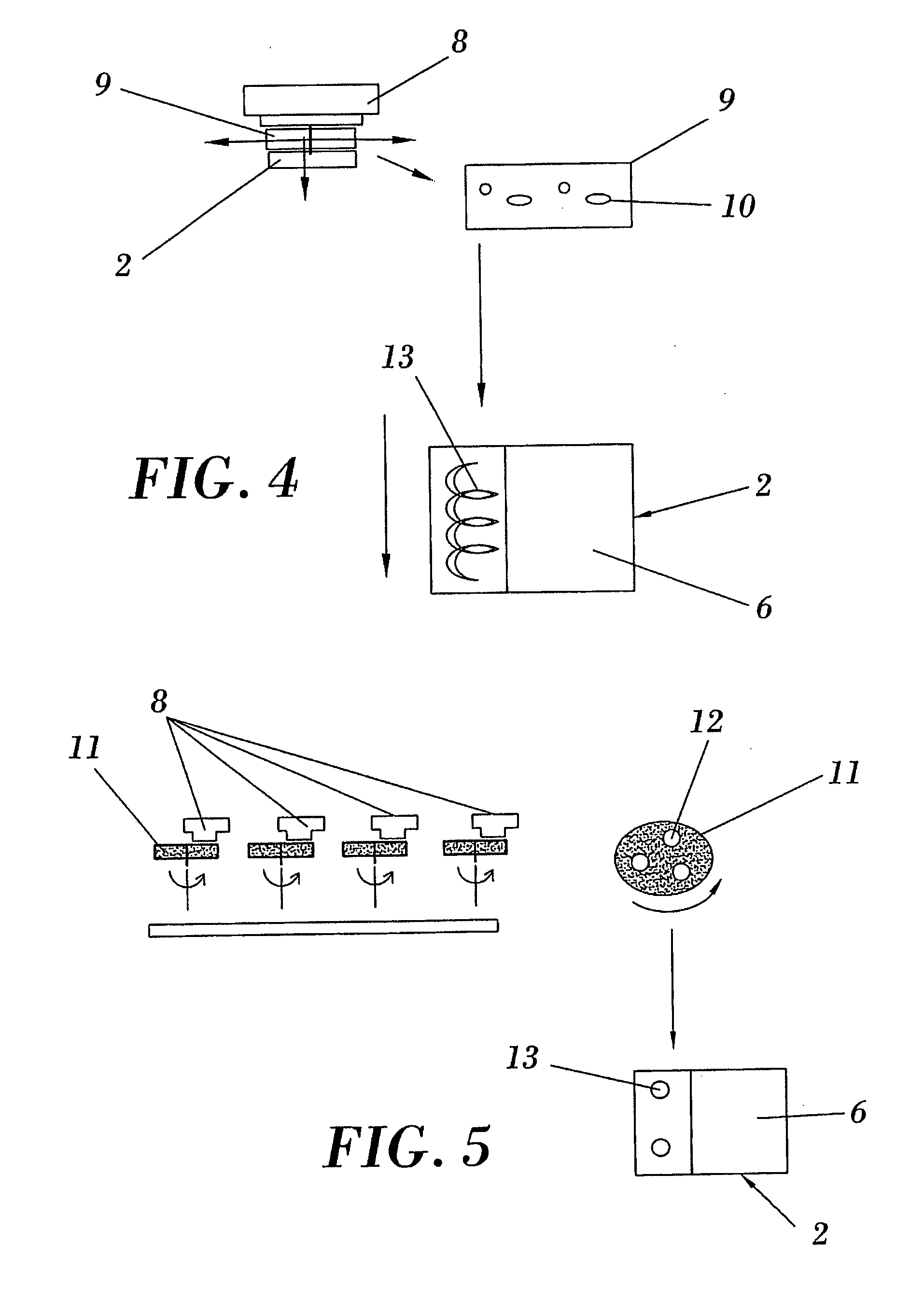

[0063] Another group of solutions will focus on the treatment subsequent to the plasma treatment. This treatment consists of a deposition of a vaporized monomer together with hydrophilic groups. This gives properties that last with time, as the anchoring of the functional groups is much stronger.

[0064] The use of plasma as pre-treatment means the activation of the nonwoven fabric's fibers for subsequent coating treatment by deposition of a vaporized monomer with philic functional groups. Said deposition is performed in the areas of the nonwoven fabric previously treated with plasma. It is necessary to provide the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical surface tension | aaaaa | aaaaa |

| critical surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com