Supercritical refrigeration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

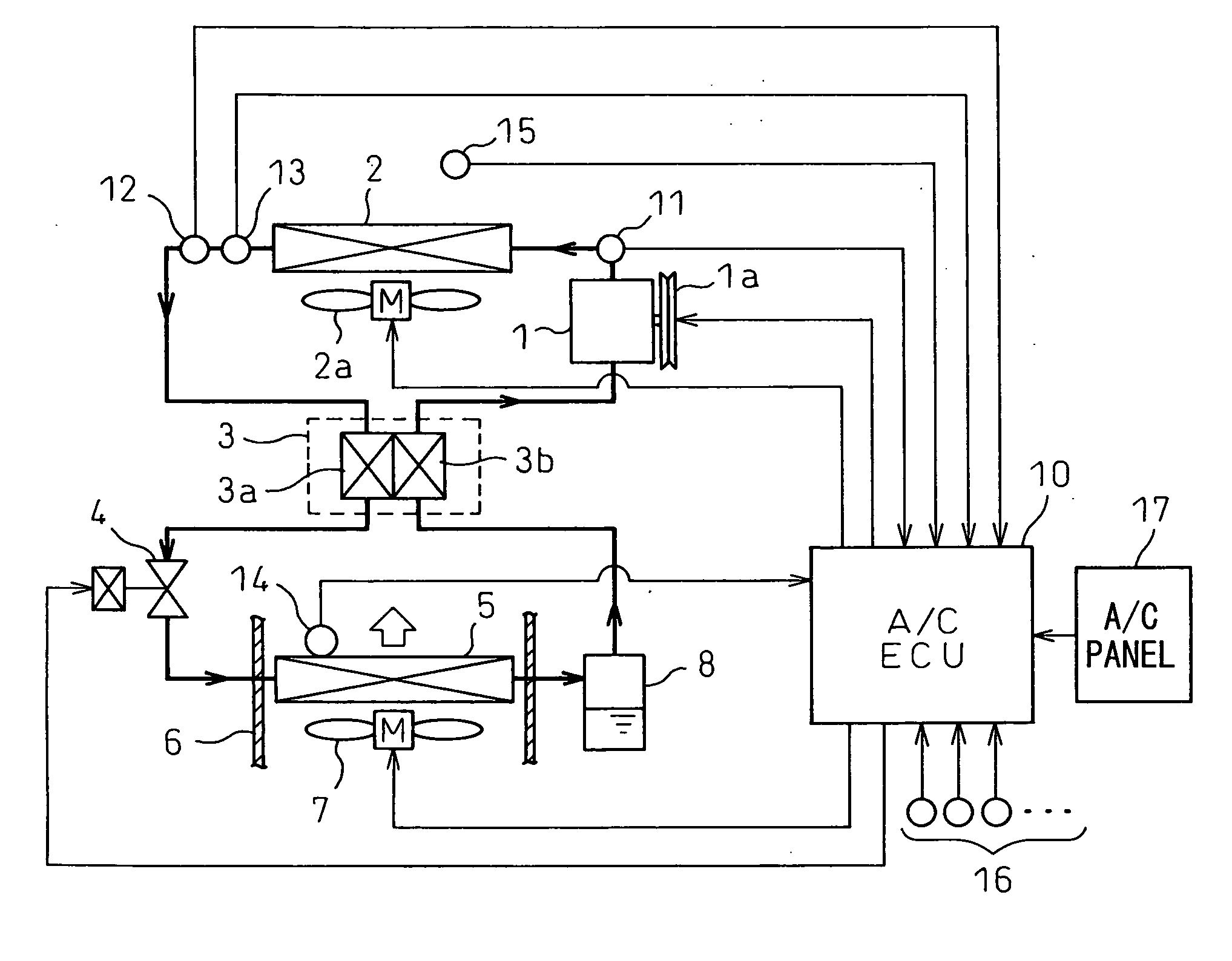

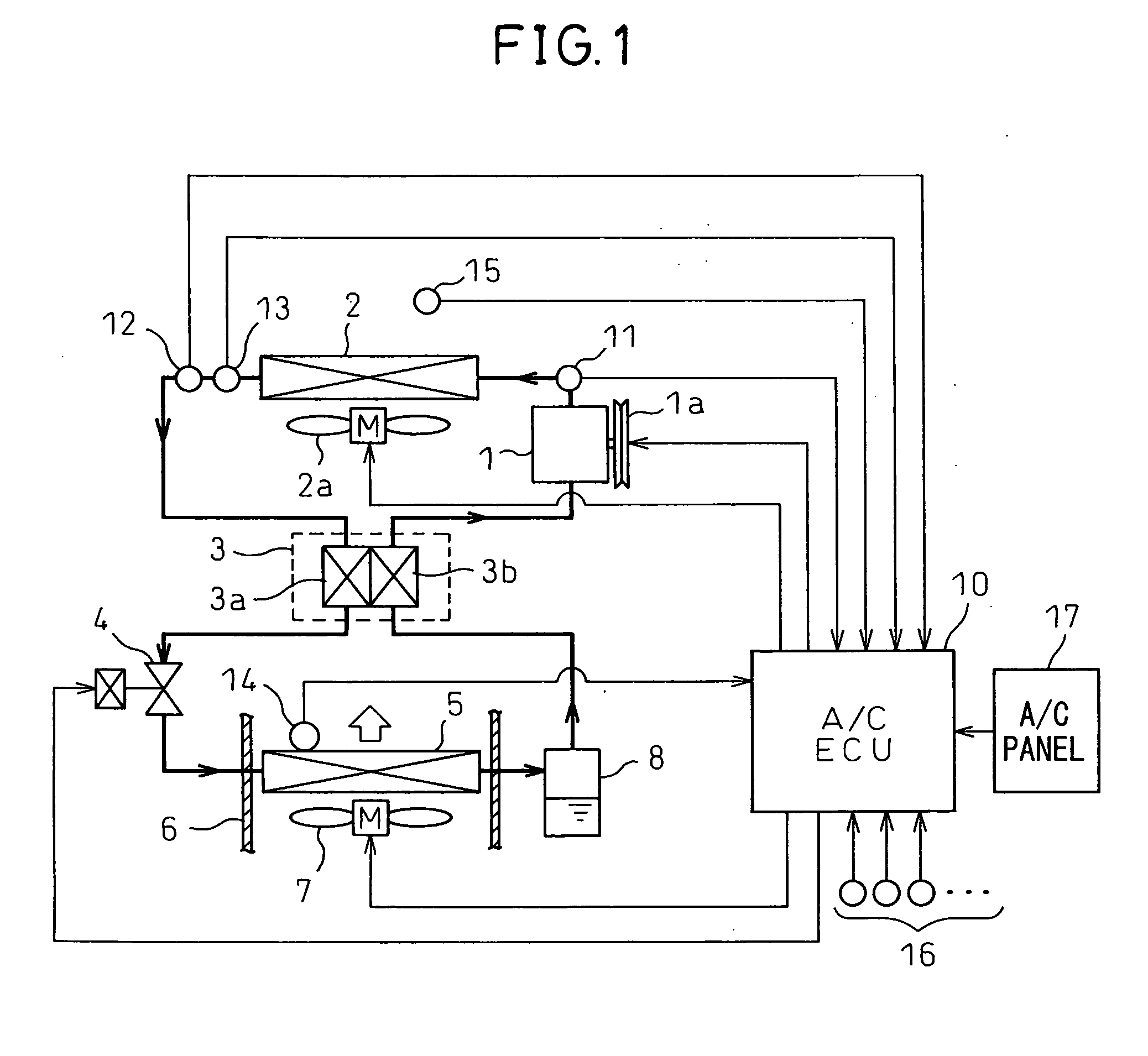

[0034]FIG. 1 is a diagram showing a configuration of the refrigeration cycle for an automotive air conditioning system according to a first embodiment of the invention. This refrigeration cycle uses CO2 as a refrigerant with the high pressure exceeding the critical pressure (supercritical state). This refrigeration cycle, therefore, constitutes a supercritical refrigeration cycle.

[0035] A compressor 1 for sucking in and compressing the refrigerant is either a fixed displacement refrigerant compressor or a variable displacement refrigerant compressor rotationally driven through an electromagnetic clutch 1a by the engine of an automotive vehicle not shown. The compressor 1 may be configured of an electrically-operated compressor.

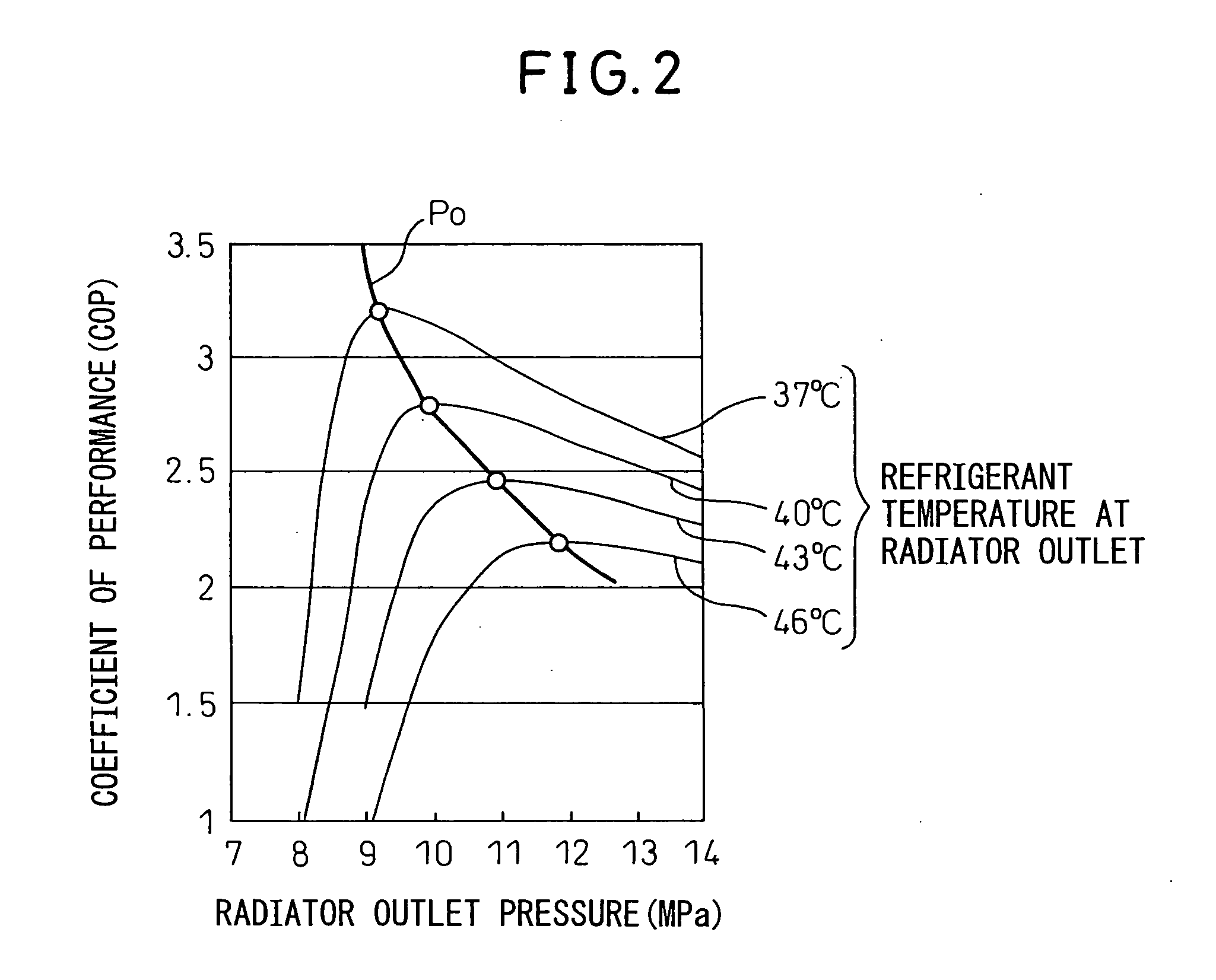

[0036] A high-pressure radiator 2 generally called a gas cooler is arranged at the outlet of the compressor 1. This radiator 2 cools the refrigerant by exchanging heat between the discharged high-temperature high-pressure refrigerant in a supercritical state...

second embodiment

[0073] The first embodiment represents a case in which the cooling fan 2a of the radiator shown in FIG. 3 is always controlled without determining whether the cycle operation is in a supercritical state or a subcritical state. According to the second embodiment, on the other hand, as shown in FIG. 6, it is determined whether the cycle operation is in a supercritical state or a subcritical state as shown in FIG. 6 and, based on this determination, the control operation of the cooling fan 2a of the radiator is switched.

[0074]FIG. 6 is a flowchart showing the operation of controlling the cooling fan 2a of the radiator according to the second embodiment. Steps S1 to S5 are identical to those of FIG. 3. According to the second embodiment, step S6 of FIG. 6 determines in step S6 whether the actual high pressure Ph detected by the pressure sensor 12 is higher than the critical pressure of the CO2 refrigerant or not.

[0075] In the case where the actual high pressure Ph is higher than the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com