Boot for a binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The object of the invention is to devise a boot for a binding which belongs to the initially named technical domain, which comprises a versatile and light alternative to existing boots for bindings, and which has high walking comfort.

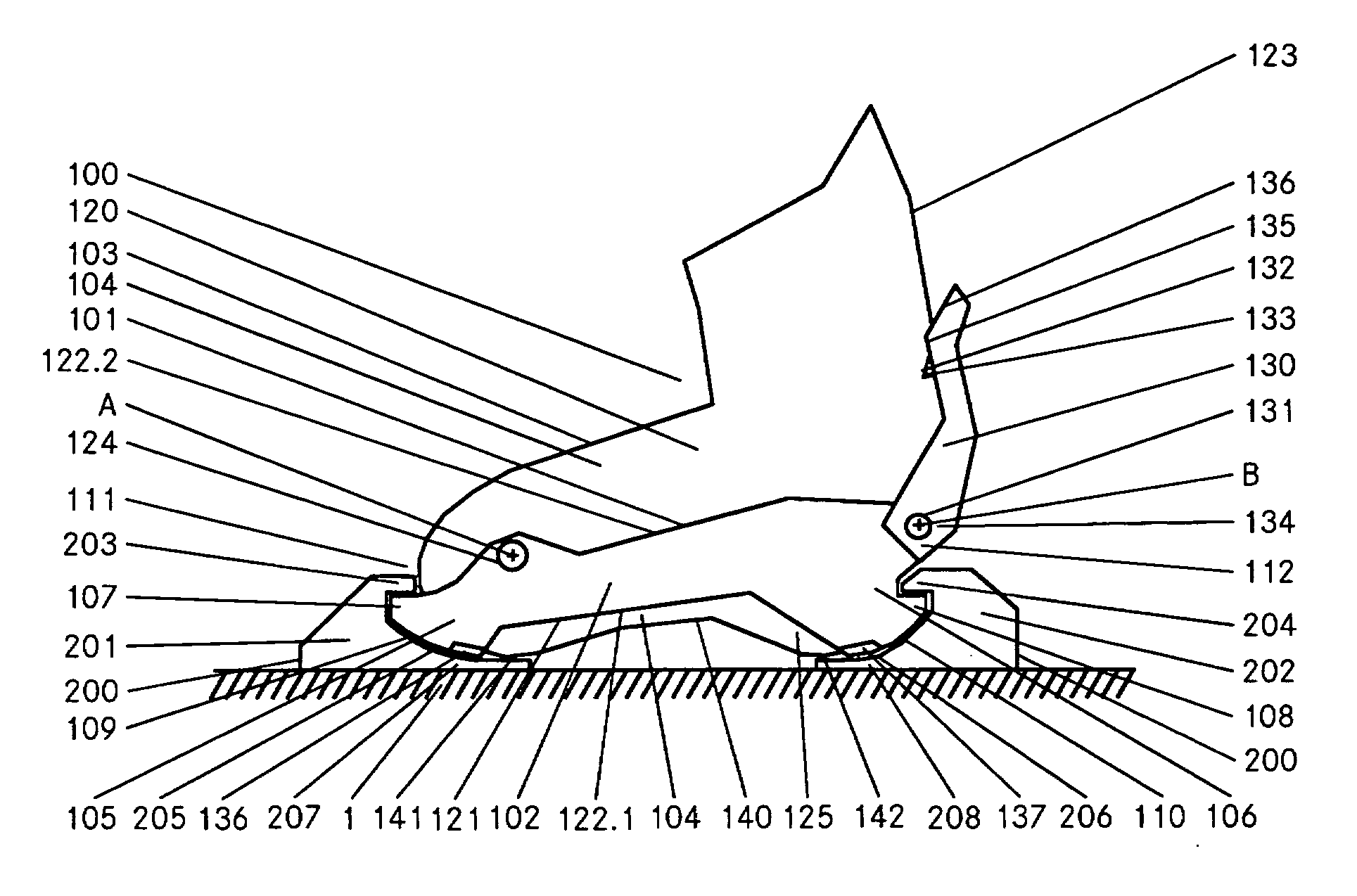

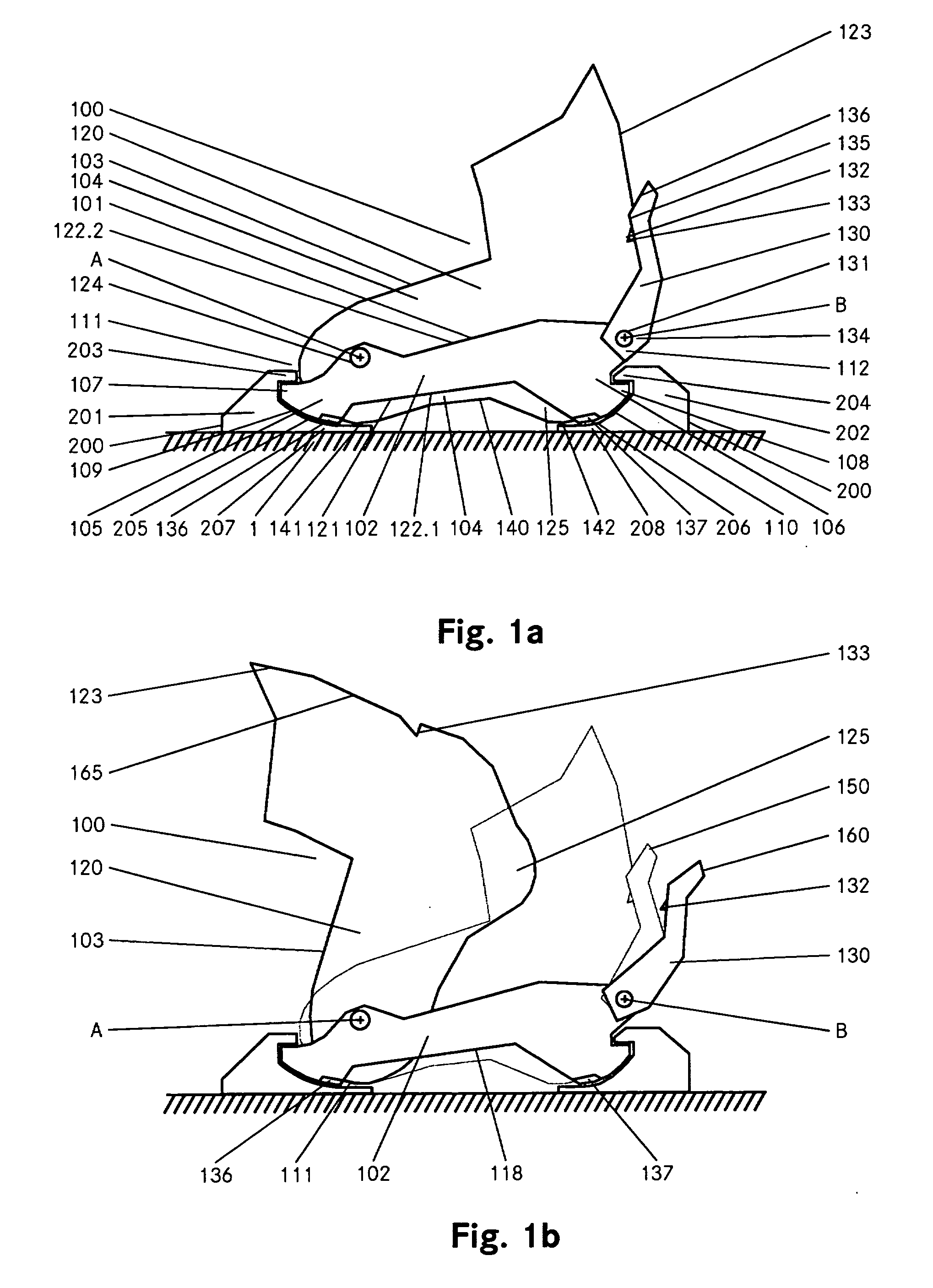

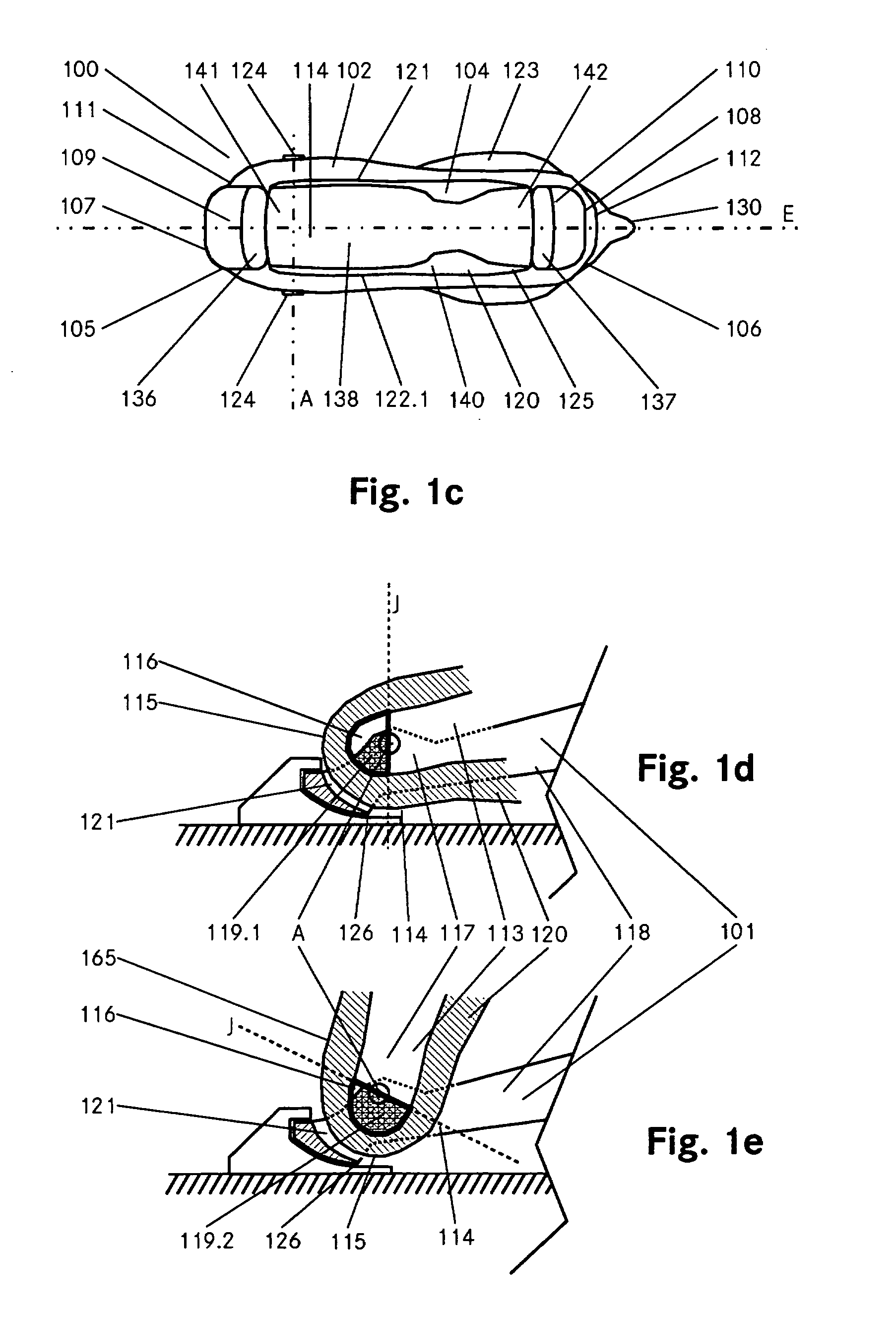

[0013] This object is achieved by the features of claim 1. As claimed in the invention the boot for the binding, especially a ski boot, comprises an outer shell for accommodating and holding the foot and a coupling part attached to the outer shell. The coupling part is used for fastening the boot in a binding. In the state held in the binding, the boot in the boot tip region and in the boot heel area is held by the binding on the coupling part. The coupling part has a connection to the outer shell such that the outer shell can be lifted off the coupling part in the heel area in executing a walking motion and can be lowered again onto it, while the coupling part is fastened in the binding. In doing so the outer shell can be pivoted around a geome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com