Shaft drive for a power loom

a technology of power looms and shaft drives, which is applied in the direction of looms, dollies, textiles and papermaking, etc., can solve the problems of high cost of modulation gears and large structural volume of cams and modulation gears on the whole, and achieves low structural size and material use, considerable torque, and simple and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

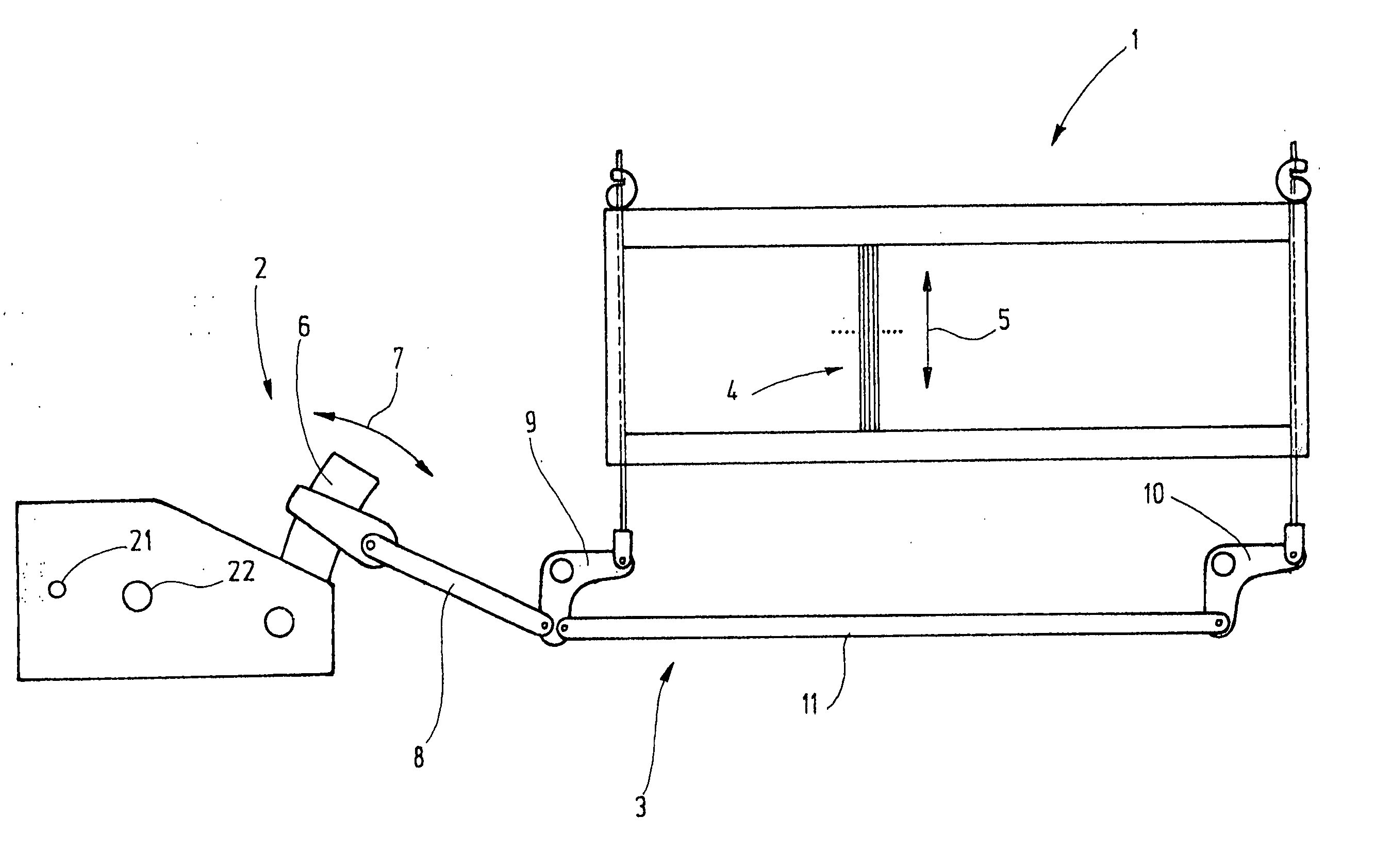

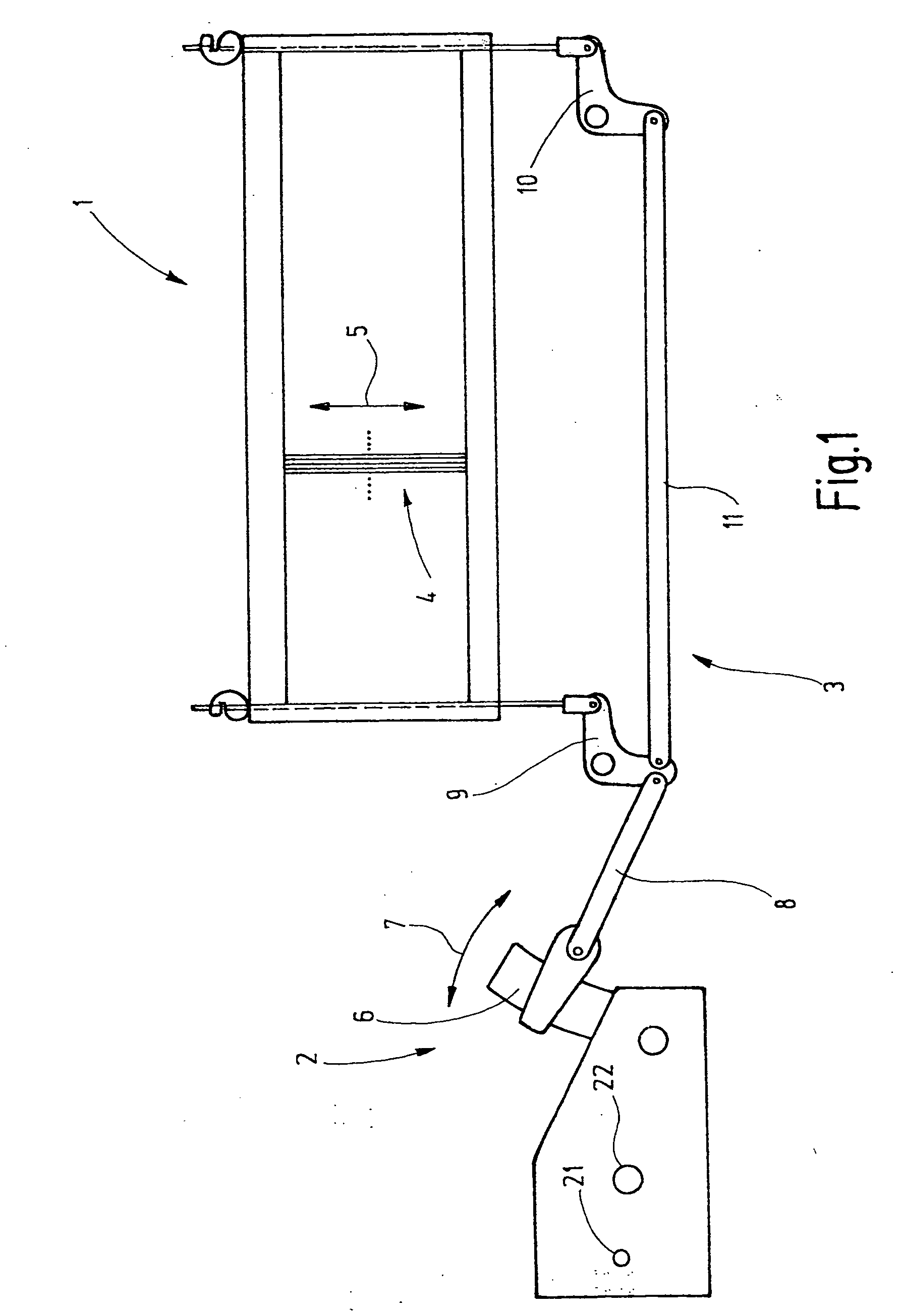

[0024]FIG. 1 illustrates a heddle shaft 1 with thereto assigned heddle machine ore dobby 2, which drives the shaft via a rod assembly, embodied as lever gear 3. FIG. 2 shows that additional heddle shafts 1a, 1b, etc. are provided parallel to the heddle shaft 1, wherein these shafts are also driven by the heddle machine 2. Insofar, this arrangement is a traditional arrangement. The heddle shafts, which function to drive heddles 4 up and down as indicated by arrow 5, are moved up and down by the lever gear 3. For this, the swinging movement (arrow 7), executed by a rocker 6 functioning as power take-off for the heddle machine 2 is converted by the lever gear 3 into the vertically directed shaft movement with the aid of a steering gear 8, an angle lever 9, 10, and a connecting rod 11.

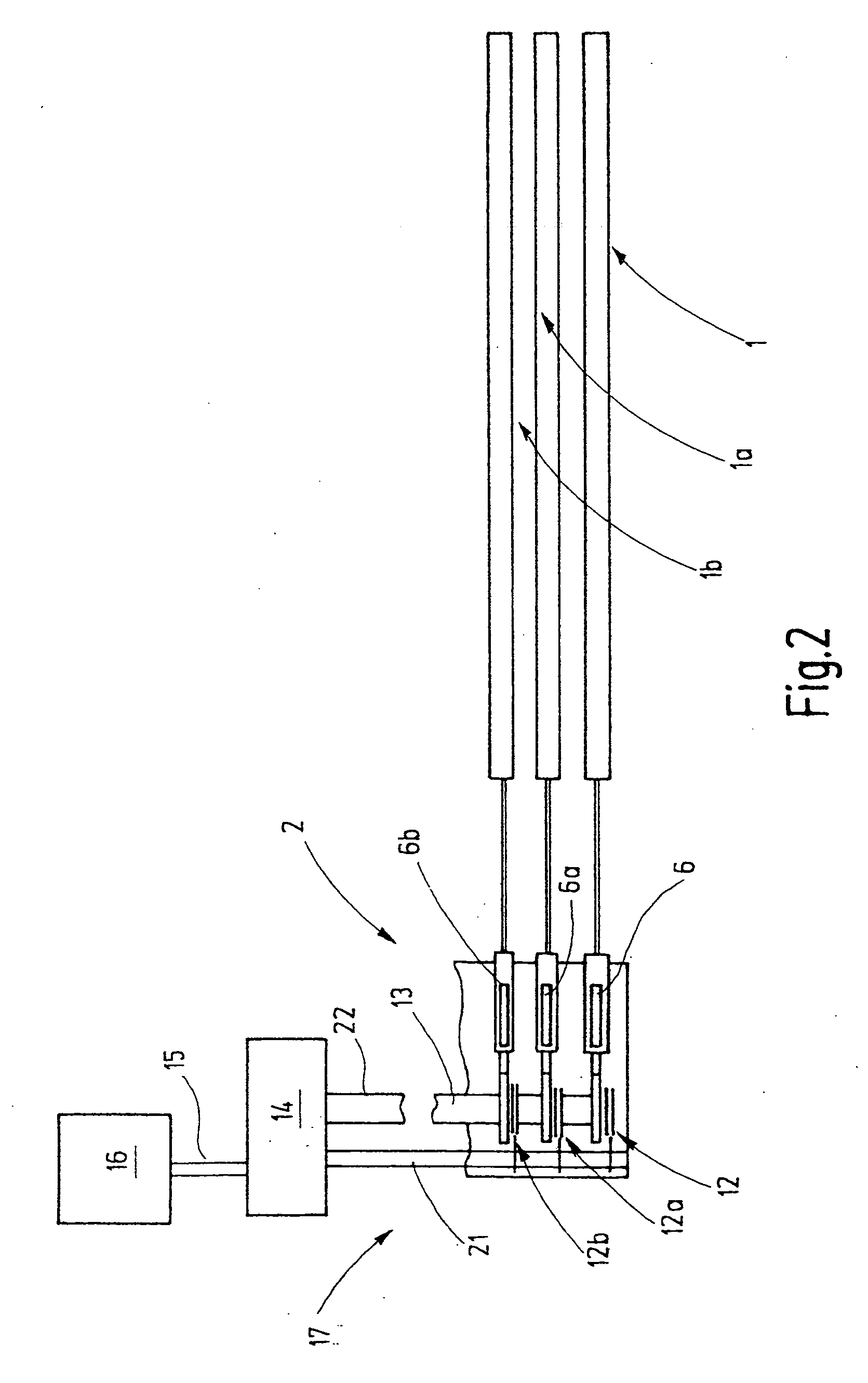

[0025] As shown in FIG. 2, the heddle machine 2 is provided with rockers 6a, 6b as power take-off for driving the additional heddle shafts 1a, 1b. These rockers are driven by means of a shaft 13, via coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com