Hand-held power tool with ratchet percussion mechanism

a technology of percussion mechanism and hand-held power tools, which is applied in the direction of percussive tools, manufacturing tools, drilling pipes, etc., can solve the problems of affecting energy loss, deformation of the housing, and affecting the operation efficiency, so as to increase the operation efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

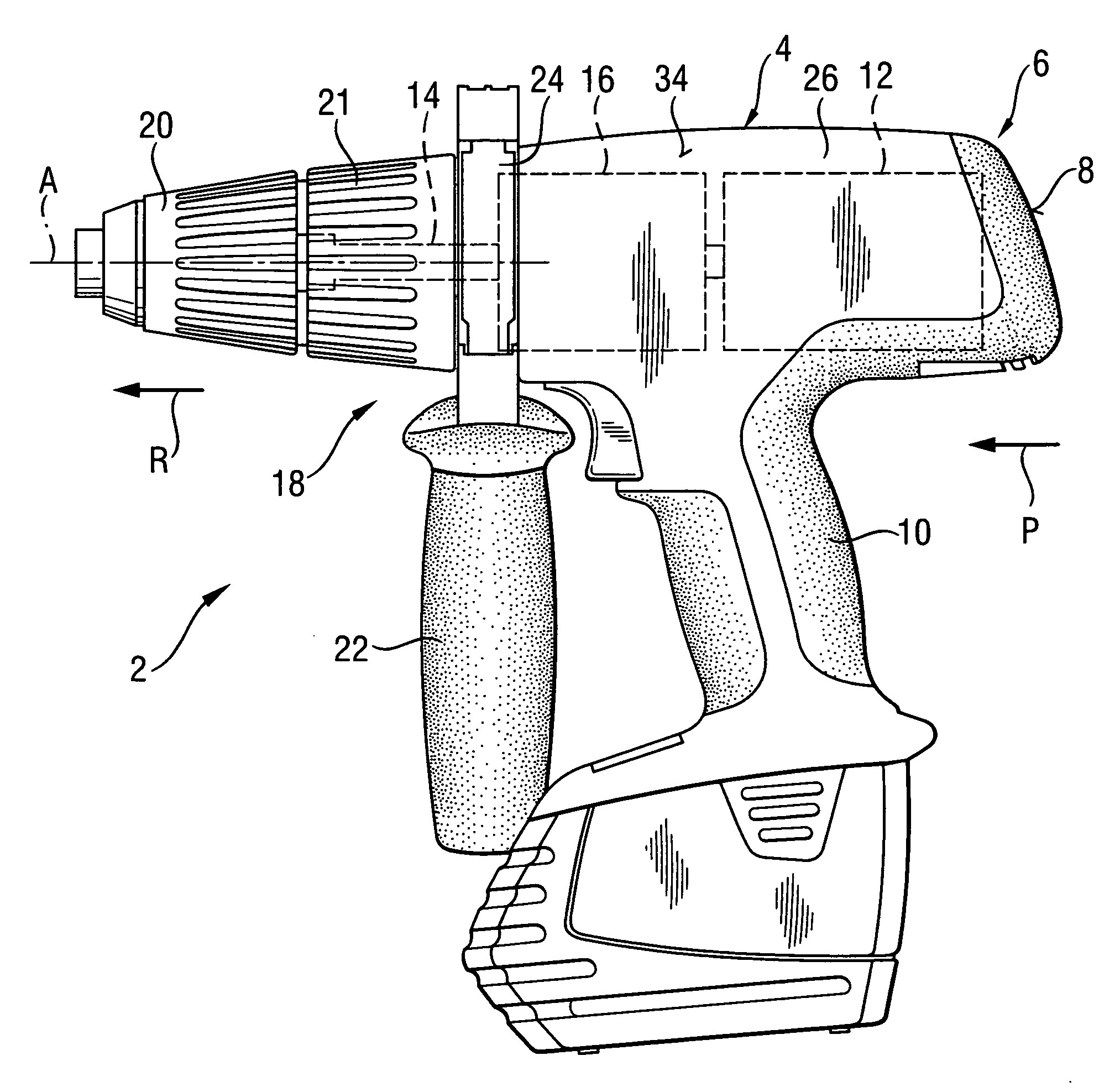

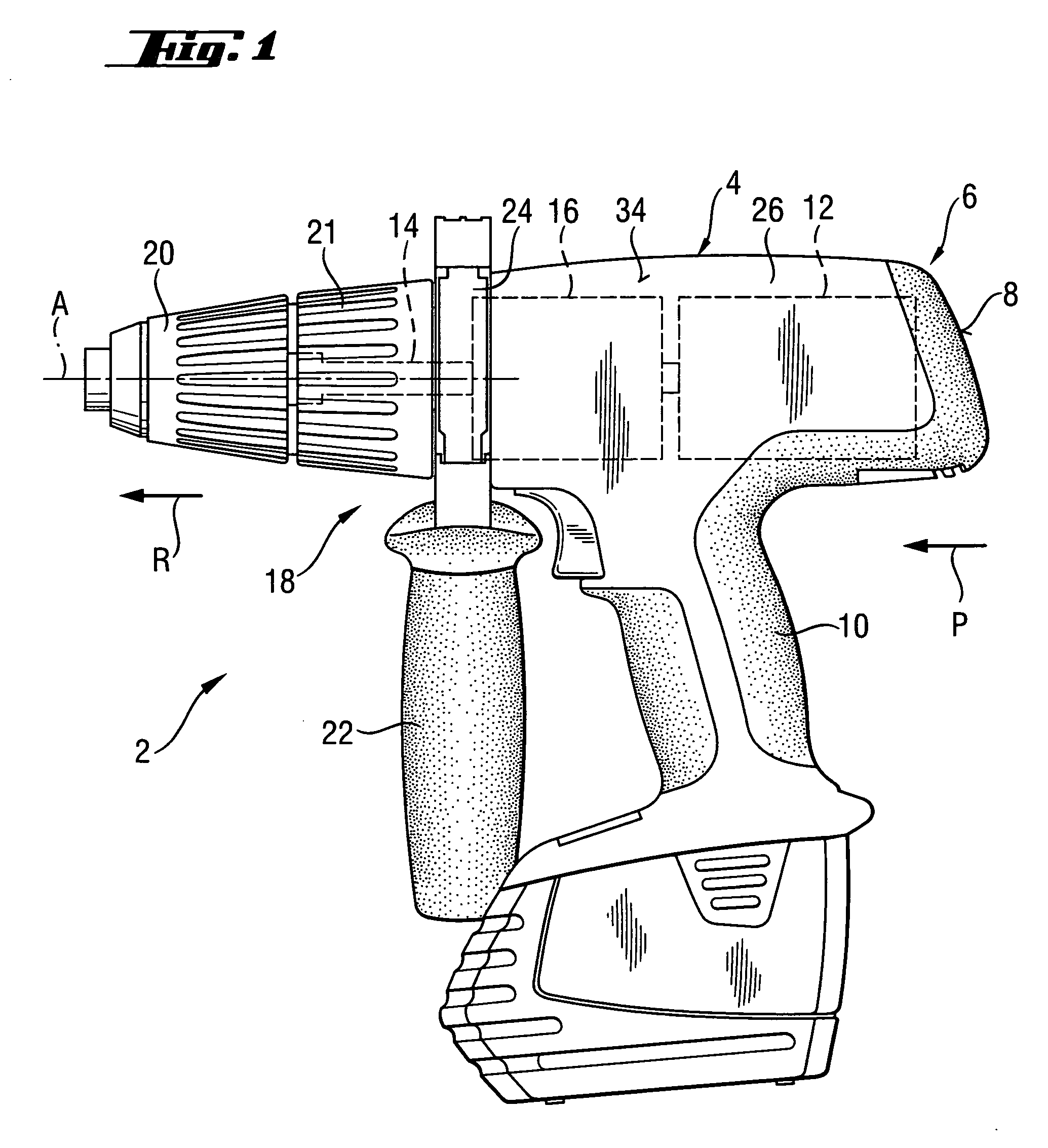

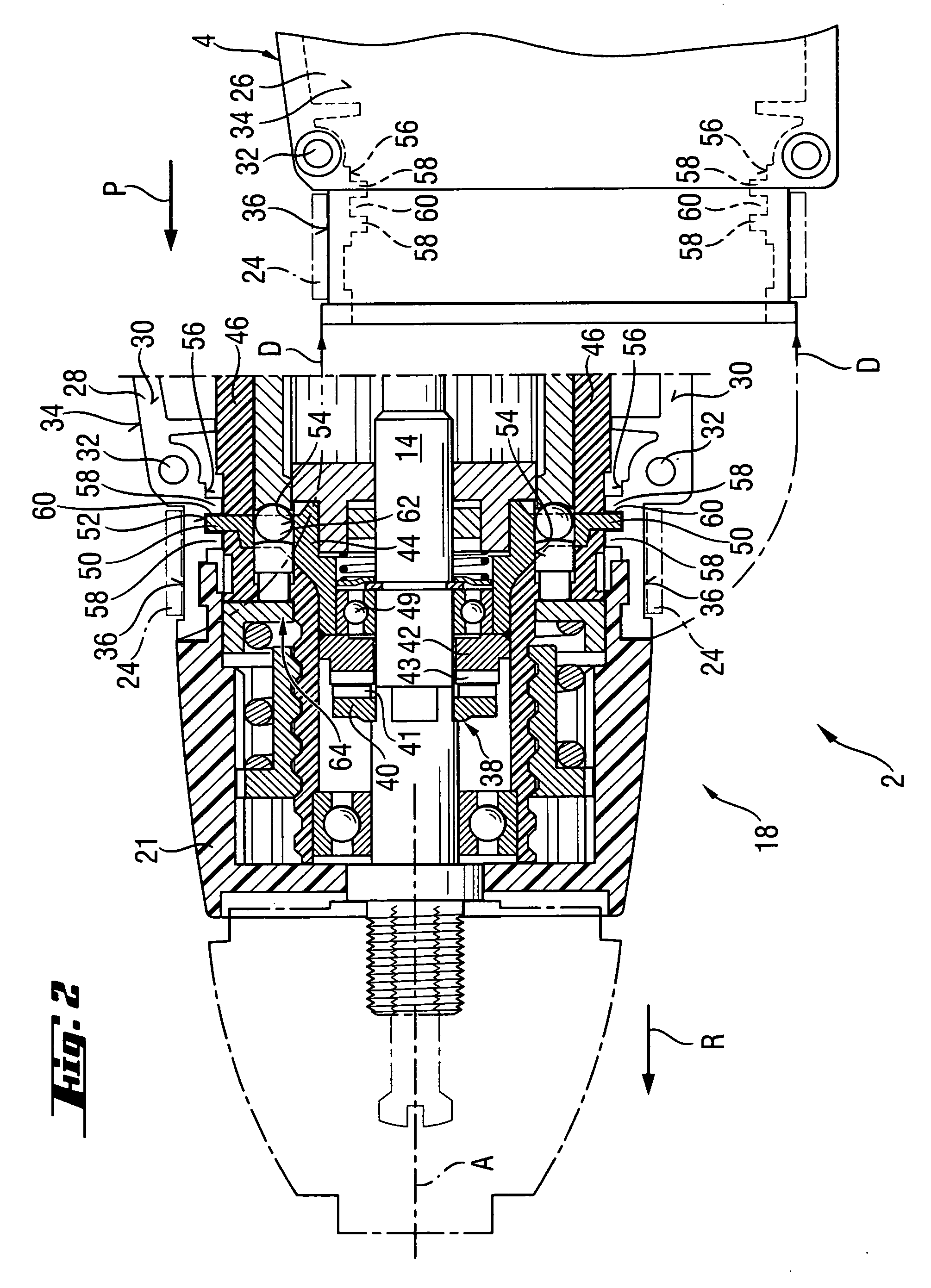

[0026]FIG. 1 shows a hand-held power tool 2 in the form of a battery-operated screw-driving power tool with an axial impact function. The screw-driving power tool has a main housing 4 of shell-type construction which has two parts and which forms a contact pressing surface 8 at its rear end 6 and from which a pistol-like handle 10 projects laterally. A motor 12 is accommodated in the main housing 4. The motor 12 rotates a tool spindle 14 around an operational axis A by means of a gear unit 16.

[0027] The tool spindle 14 projects in operational direction R from a working tool-end side 18 of the main housing 14 and is connected at its free end to a tool holder 20 in the form of a chuck for a joint rotation therewith. The tool spindle 14 projects through an adjusting sleeve 21 which is supported for rotation between the main housing 4 and the tool holder 20 for adjusting a maximum torque.

[0028] Further, a side handle 22, which is fixedly clamped to the main housing 4 by a clamping ban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com