Exhaust gas purification apparatus, exhaust gas purification method, and sulfur component trapping agent for internal combustion engine

a technology of exhaust gas purification and purification method, which is applied in the direction of mechanical equipment, machines/engines, surface coverings, etc., can solve the problems of deteriorating catalyst activity and difficulty in purifying nox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Installation of Sulfur Component Oxidizing Catalyst

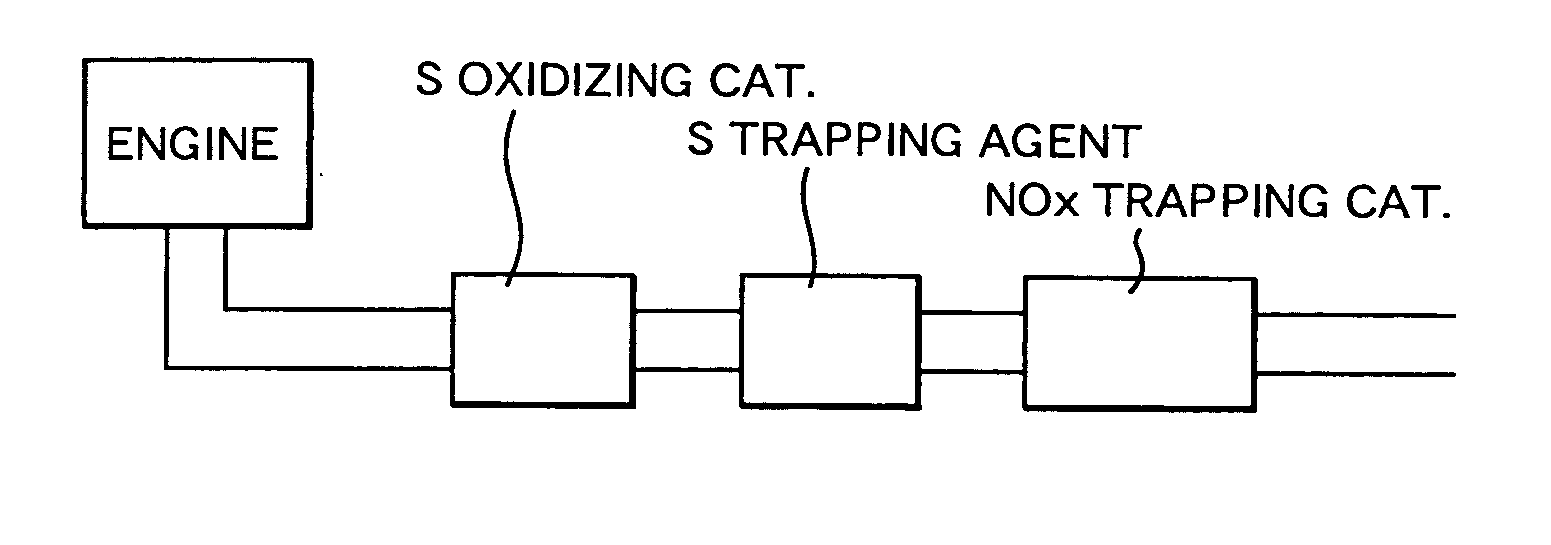

[0070] As shown in FIG. 1, the sulfur component trapping agent B (Na2CO3) was installed before the NOx trapping catalyst 1 in an engine exhaust gas duct. Further, a sulfur component oxidizing catalyst was disposed before the sulfur component trapping agent to constitute a purification apparatus. As the sulfur component oxidizing catalyst, Al2O3 with Pt prepared in the same manner as in the method for preparing the NOx trapping catalyst was used. The sulfur component oxidizing catalyst comprises 190 g of alumina per 1 liter of the honeycomb, 2.792 g of Pt, in conversion of elements.

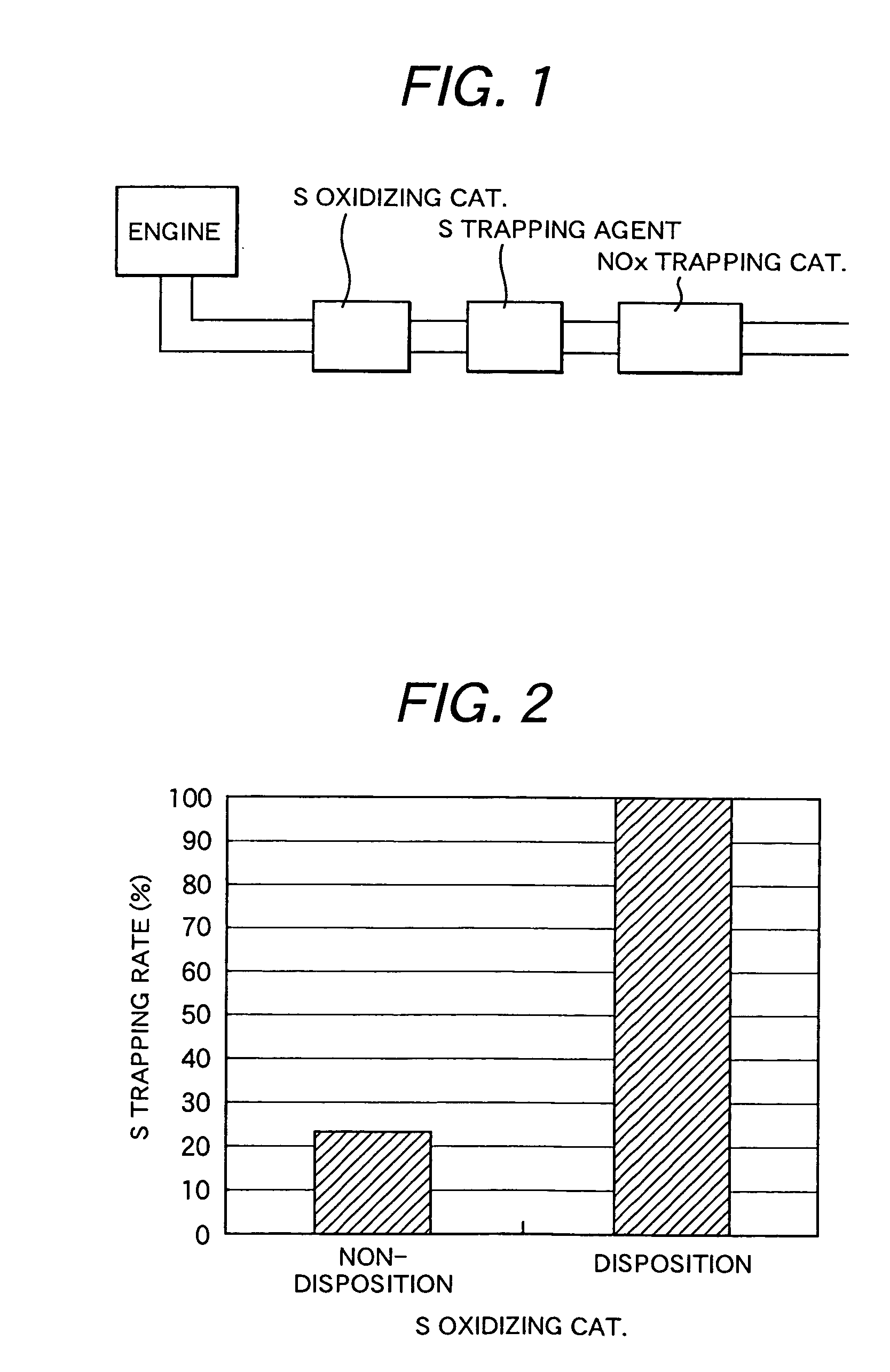

[0071] In FIG. 1, a comparative embodiment 1 had no sulfur component oxidizing catalyst. SOx containing lean gas was supplied to the sulfur component trapping agents to evaluate sulfur trapping rates by the sulfur component trapping agents.

[0072] Temperatures of the sulfur component oxidizing catalysts and sulfur component trapping agents were 400 degre...

embodiment 2

Evaluation of Sulfur Component Trapping Performance of the Sulfur Component Trapping Agent

[0077] In the system shown in FIG. 1, amounts of sulfur trapped by the sulfur component trapping agent were calculated in a thermodynamic method when SOx containing lean gas was supplied to the sulfur component trapping agent. As calculation software, MALT2 (thermodynamic database for personal computer; Japan Society of thermodynamics) was used.

[0078] A temperature of the sulfur component trapping agent was 300° C. A flow rate of the SOx containing lean gas was 3 L / min. The sulfur components in the gas were oxidized to SO3 by the sulfur component oxidizing catalyst disposed before the sulfur component trapping agent. Thus, a concentration of SO3 was estimated as 150 ppm. A period of flow time was 1000 hours. Gas components other than SO3 were shown in Table 3. The sulfur trapping rates were calculated by the equation (6).

TABLE 3Sulfur trapping rates of the sulfur component trappingagents A,...

embodiment 3

Evaluation on Decomposition Sulfates of Sulfur Component Trapping Agents

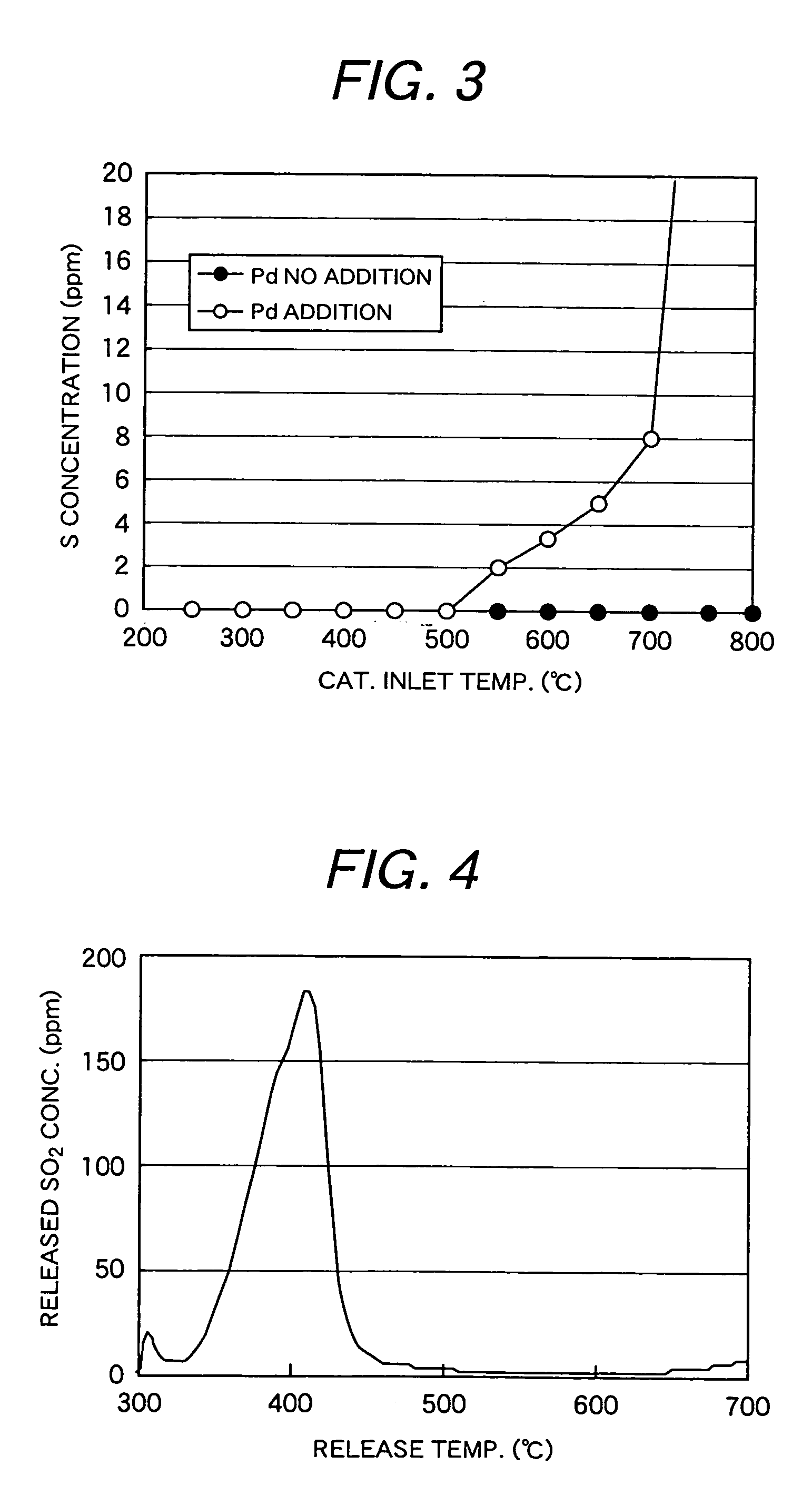

[0083] Decomposition of sulfates of the sulfur component trapping agents was evaluated. Sulfates / Al2O3 prepared by drying and mixing various sulfates and Al2O3 were used. A concentration of the sulfur component trapping agents per 10 grams of alumina was 0.04 mol in conversion of elements.

[0084] As samples of sulfates of the sulfur component trapping agents, sulfates of alkali metals, alkaline earth metals, and sulfates of Ce, Al, La, Y and Ni were chosen.

[0085] Powders of the above sulfur component trapping agents were granulated into 0.85 to 1.70 mm diameter. The temperature of the sulfur trapping agents was kept at 300° C. and the rich gas shown in Table 4 was flown through the trapping agents, while elevating a temperature of from 250 to 750° C. Concentrations of sulfur components (SO2+H2S) released from the trapping agents were measured. A space velocity SV of the gas was 30,000 / h.

TABLE 4Gas compositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com