Paper sheet treating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

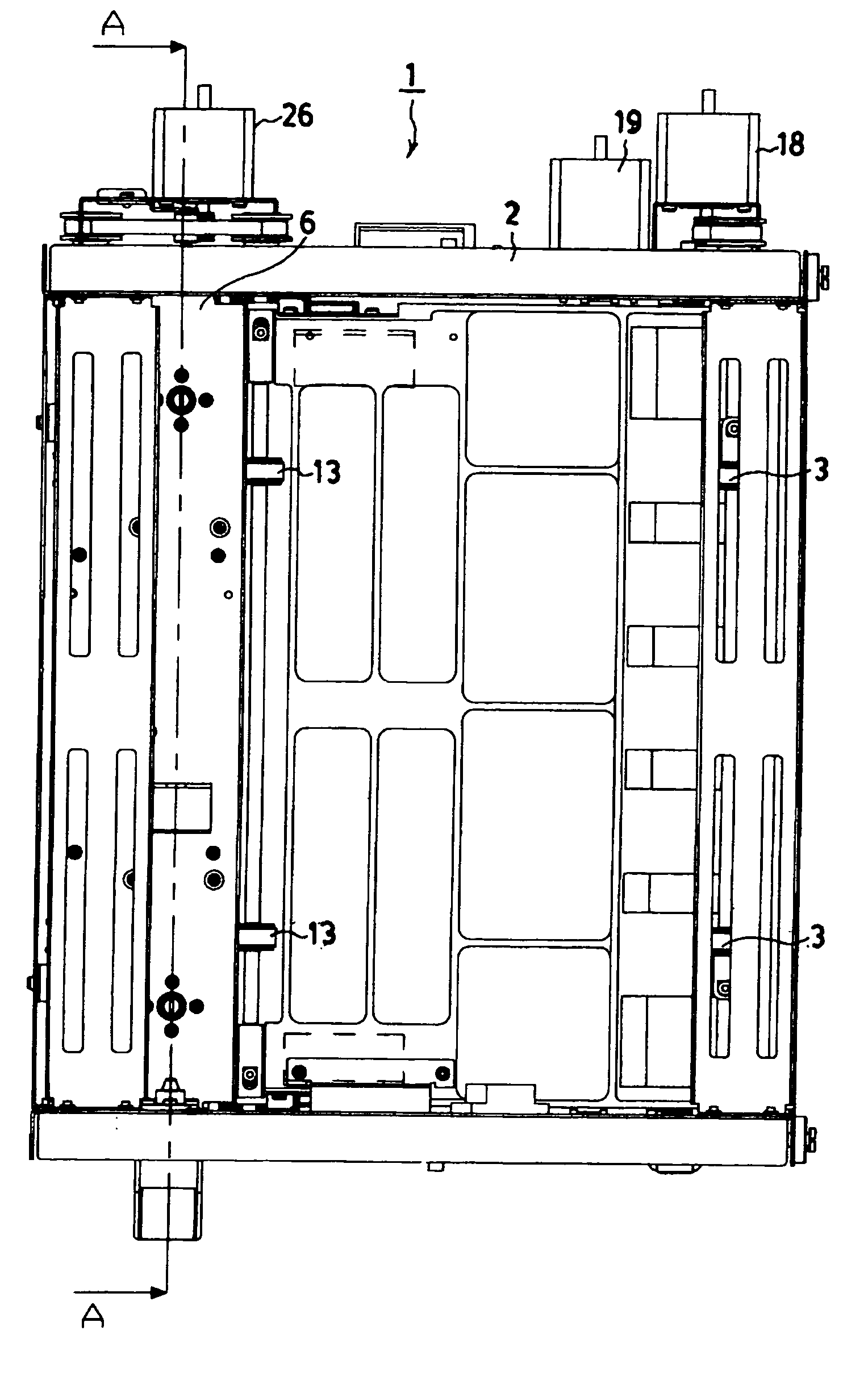

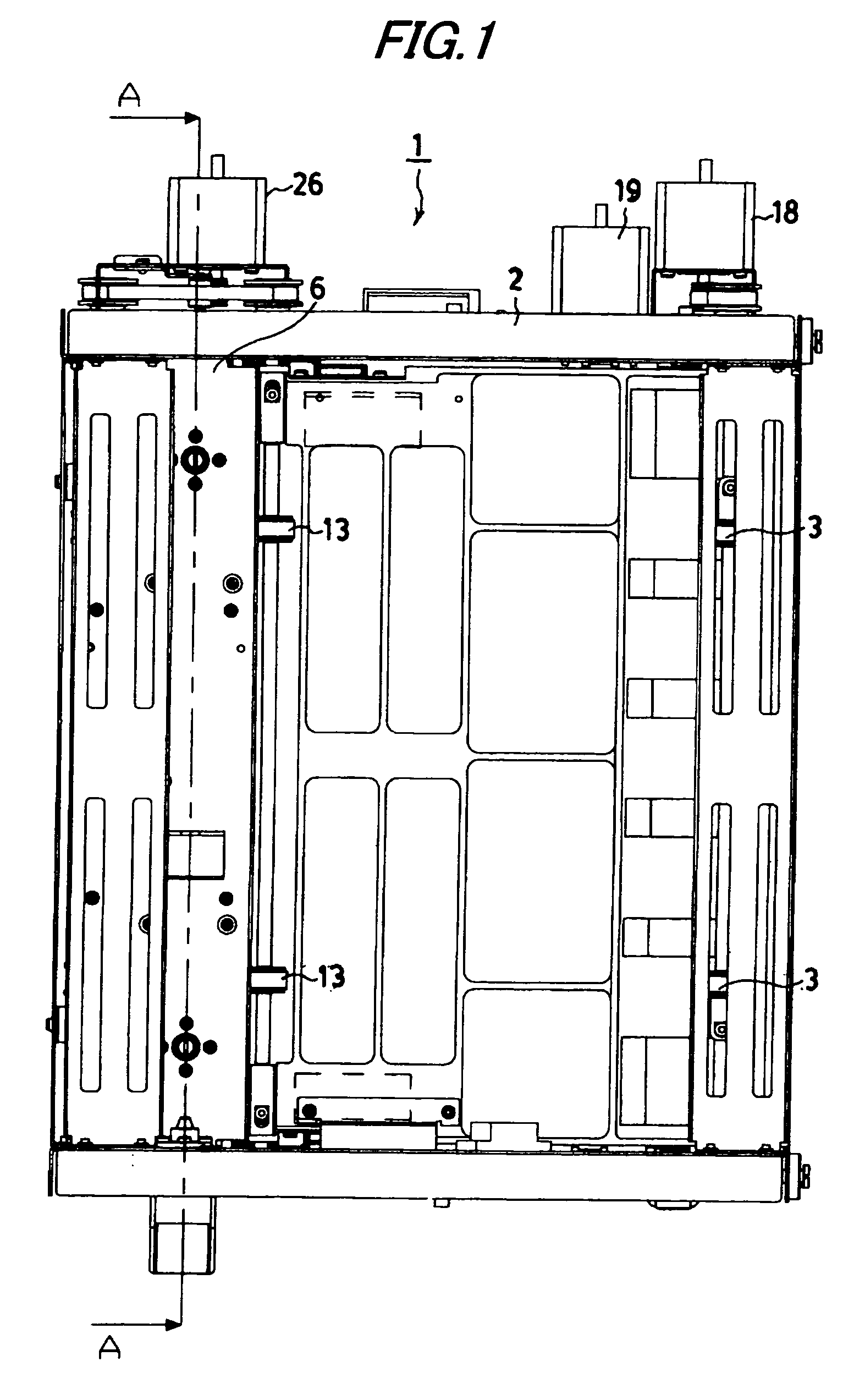

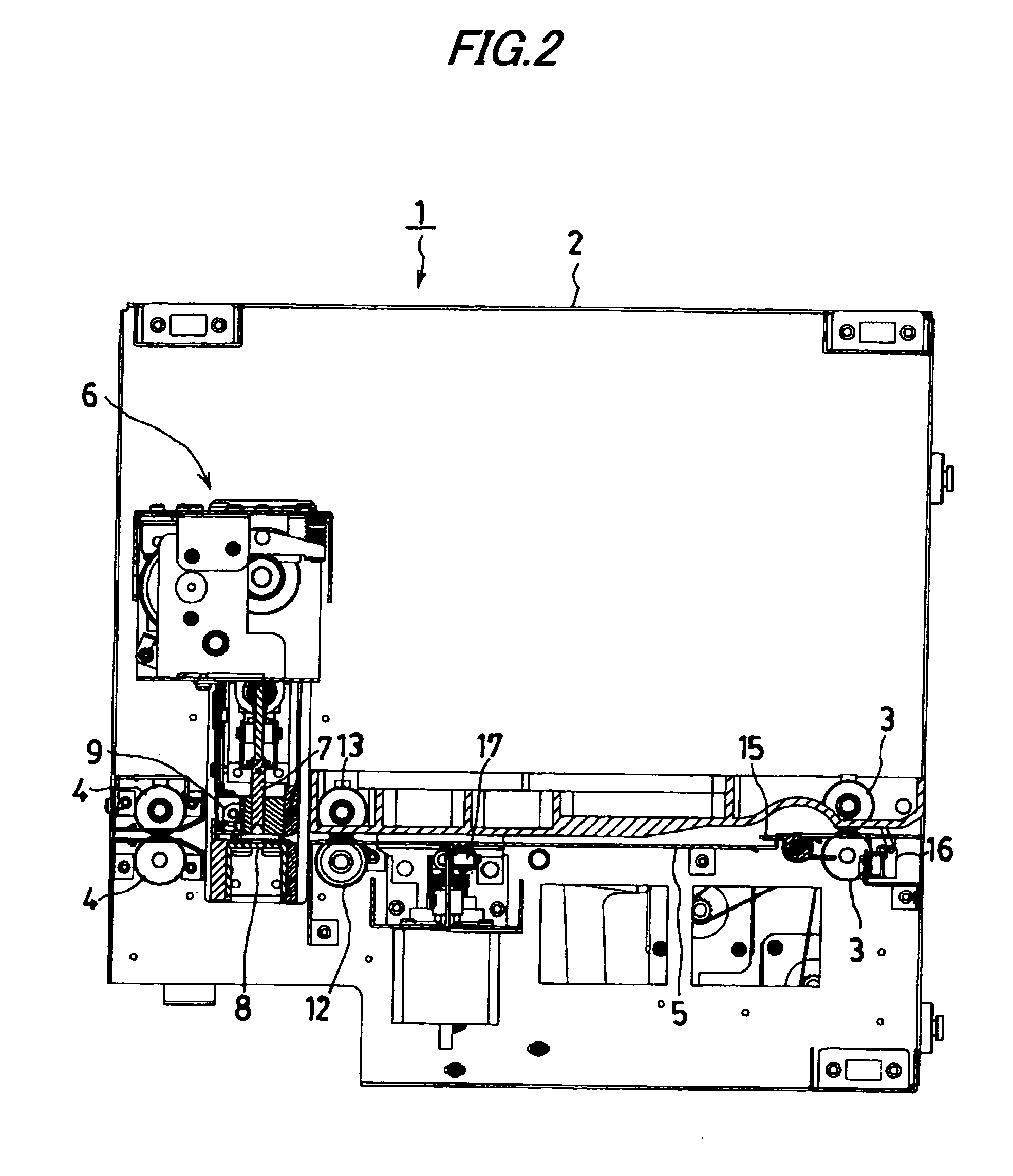

[0053]FIG. 1 to FIG. 4 show a sheet treating device which is equipped with a punching device 1 as an aftertreatment device. As shown in FIG. 2, the punching device 1 is constituted by arranging a pair of upper and lower feed rollers 3 in the front portion (as located on the right side) of a frame 2, as shown, and by arranging a pair of upper and lower discharge rollers 4 in a rear portion so that a paper sheet discharged from the (not-shown) copying mechanism unit is pulled by the feed rollers 3 and sent rearward on a horizontal sheet table 5 and is punched by a multi-hole punching unit 6 arranged just upstream of the discharge roller 4 and then discharged rearward by the discharge roller 4.

[0054] The punching unit 6 is equipped with a 30-hole type punch 7, a die plate 8, and a closing type fence 9 acting as a sheet stopper on the downstream side (as located on the left side in FIG. 2) of the sheet feed. The punching unit 6 mounts a punch driving motor 10 and a fence driving soleno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com