Method of forming conductors at low temperatures using metallic nanocrystals and product

a technology of metallic nanocrystals and conductors, applied in the field of forming conducting metallic films, can solve problems such as incompatibility with plastic substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Nanocrystal Synthesis

[0045] The synthesis of the gold nanoclusters followed that reported by Murray et al., Longmuir, 14, 17 (1998). The length of the alkanethiol molecules used as the encapsulant was varied, and the size of the resulting nanocrystal was adjusted by controlling the relative mole ratio of the encapsulant and gold. In brief, 1.5 g of tetroactylammonium bromide was mixed with 80 mL of toluene and added to 0.31 g of HAuCl4:xH2O in 25 mL of deionized (DI) water. AuCl4− was transferred into the toluene and the aqueous phase was removed. A calculated mole ratio of an alkanethiol was added to the gold solution. Thiols with lengths ranging from 4 carbon atoms to 12 carbon atoms were used. For crystals with larger diameters (˜5 nm average diameter), a thiol:gold mole ratio of 1 / 12:1 was used. For smaller diameters, nanocrystals (˜1.5 nm average diameter), a thiol:gold mole ratio of 4:1 was used. Sodium borohydride mixed in 25 mL of water was added into the organic phase wit...

example 2

Heating Tests

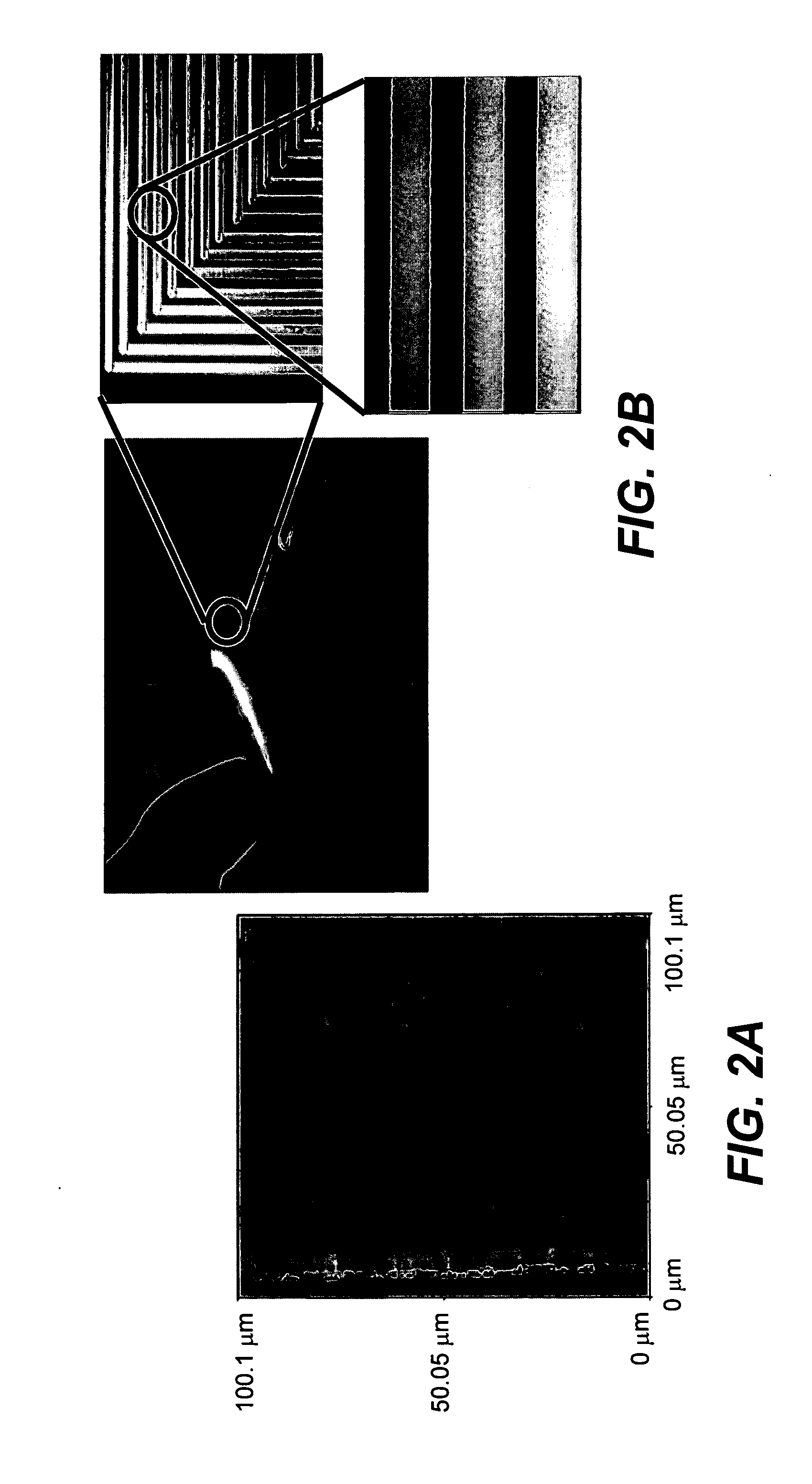

[0046] The gold nanocrystals were redissolved in toluene to form saturated solutions. To measure resistance, the solutions were then micropipetted onto an insulating substrate (either plastic or SiO2) and allowed to air dry. To confirm plastic compatibility, several commercial plastics were used. Commercial polyester films (the smooth side of 3M inkjet transparencies and the uncoated side of laser printer transparencies) generally had deformation temperatures in the range of 150°-180° C., where we defined the deformation temperature as the temperature at which the film underwent dramatic contraction. Typically, these films showed significant degradation in transparency at temperatures 10°-20° C. lower, which therefore represented an upper bound on the usable temperature range for these materials, depending on their application. Therefore, these films were used only for the lower temperature tests. For these tests, the micropipetted film was dispensed on the uncoated s...

example 3

Annealing

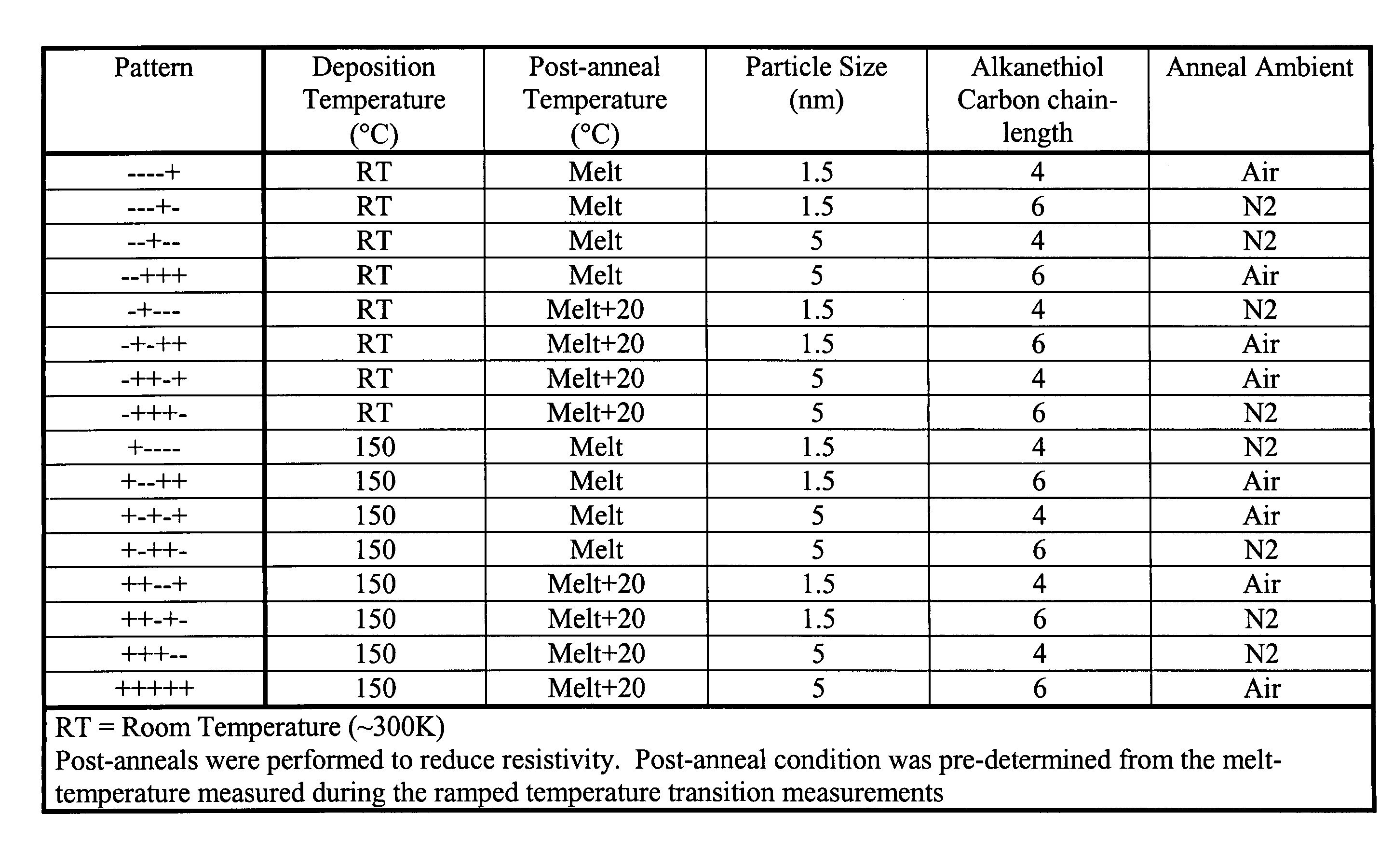

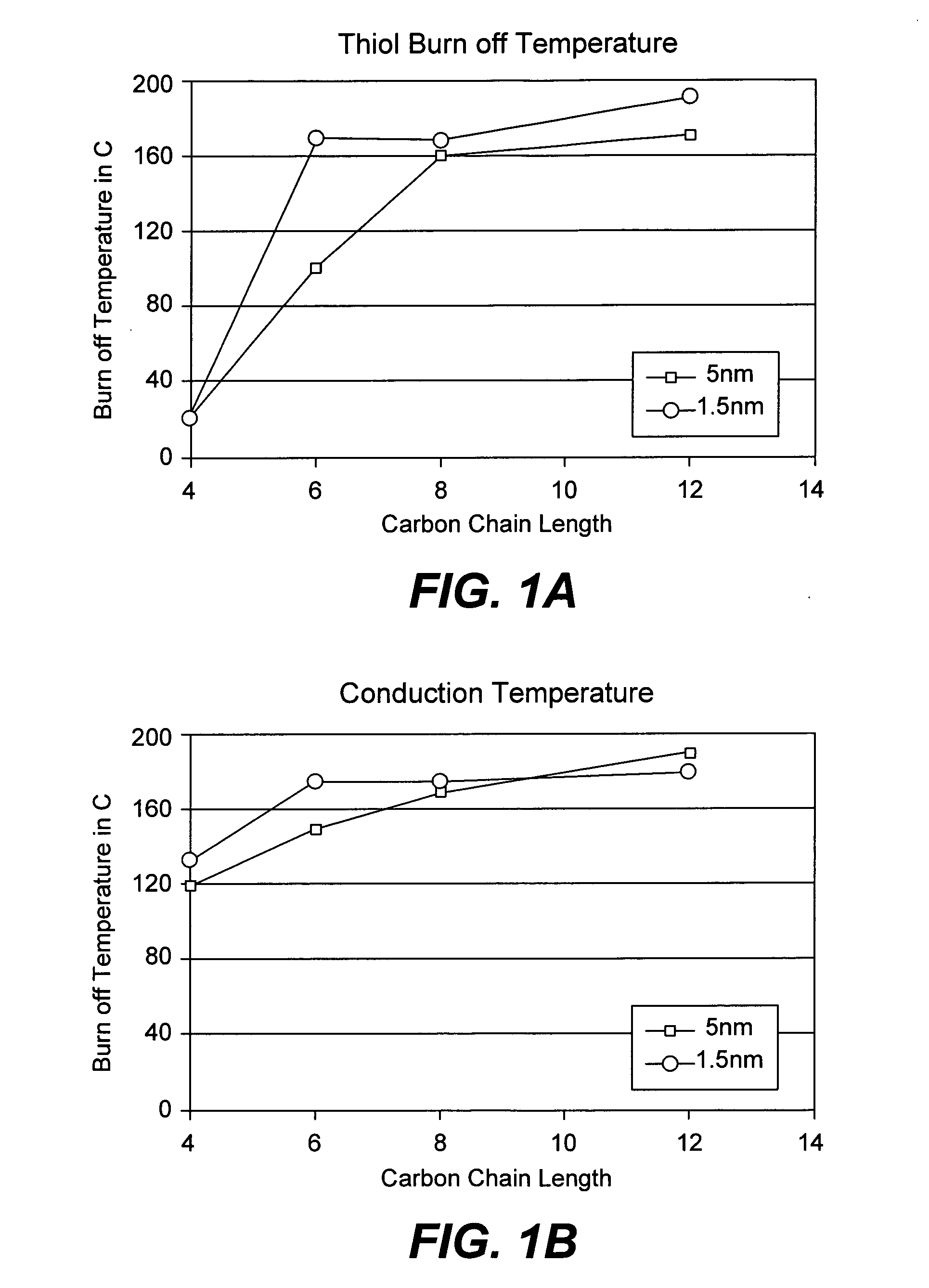

[0047] A ramped anneal was performed to determine the various transition temperatures. The thiol burn-off temperature was determined visually, by a rapid transition of the film color from black to gold, accompanied by a sublimation of the thiol in the form of a black smoke. Upon further annealing, the film underwent a color transition from a dull golden color to a shiny gold. This indicated the nanocrystal melting temperature. At this point, the film achieves a low-resistance state. Resistivity of the films were measured using a 4-point probe and an HP4156 Semiconductor parameter analyzer. FIG. 11 is a table showing the results of the annealing tests. From this table, it is apparent that the required anneal temperature is a strong function of the encapsulant carbon chain length. Nanocrystals encapsulated in dodecanethiol anneal at 170° C.-200° C., which is not plastic compatible. However, by reducing the carbon chain length to four or six, it is possible to obtain nanocry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com