System and method for filling containers with liquid under varying pressure conditions

a technology of liquid and pressure conditions, applied in the field of systems and methods for filling containers with liquid, can solve the problems of inaccurate dose volumes, difficulty in filling containers without gas pockets, inaccurate pressure in soft bags, etc., and achieve the effect of reducing the pressure in soft bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

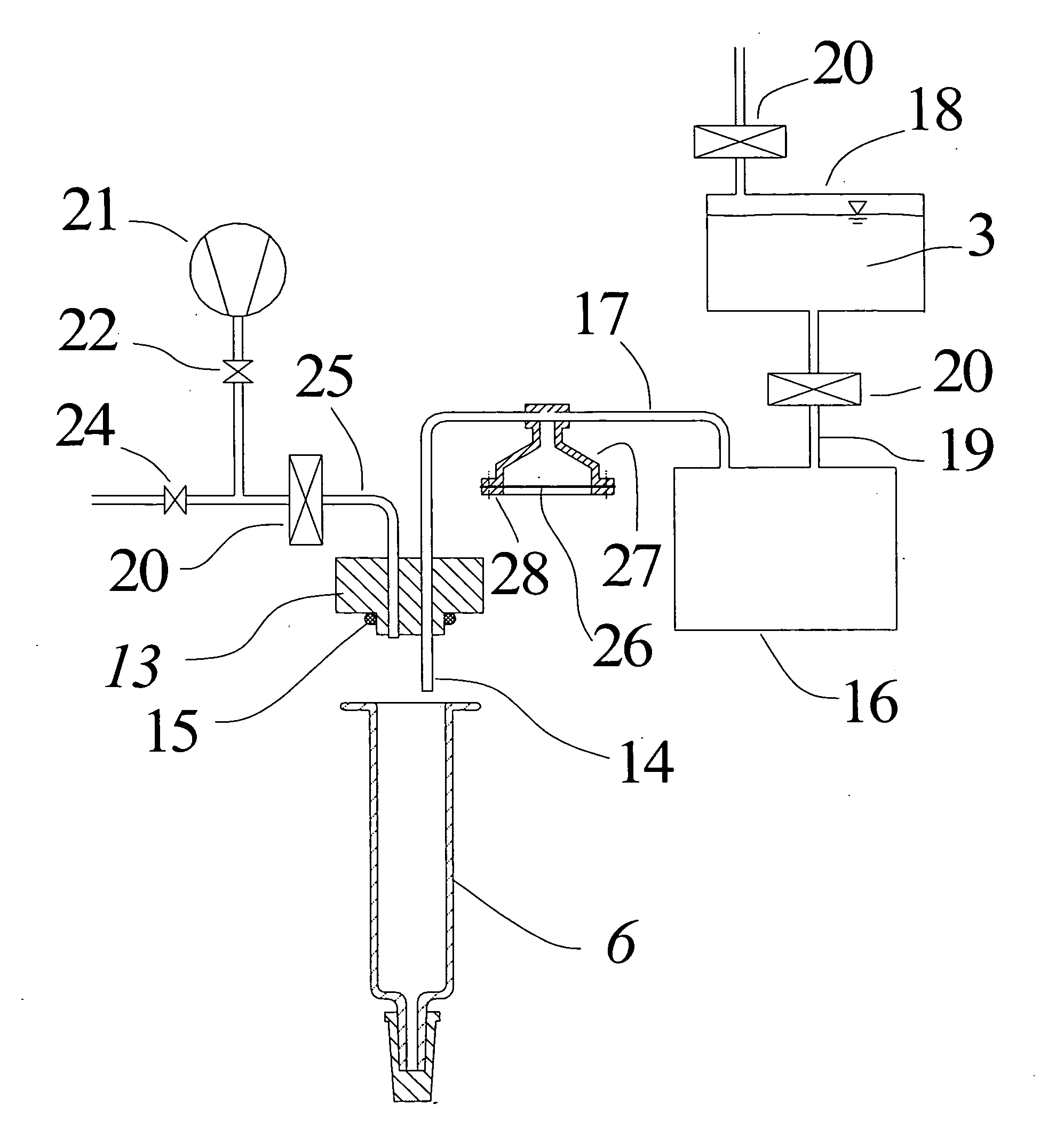

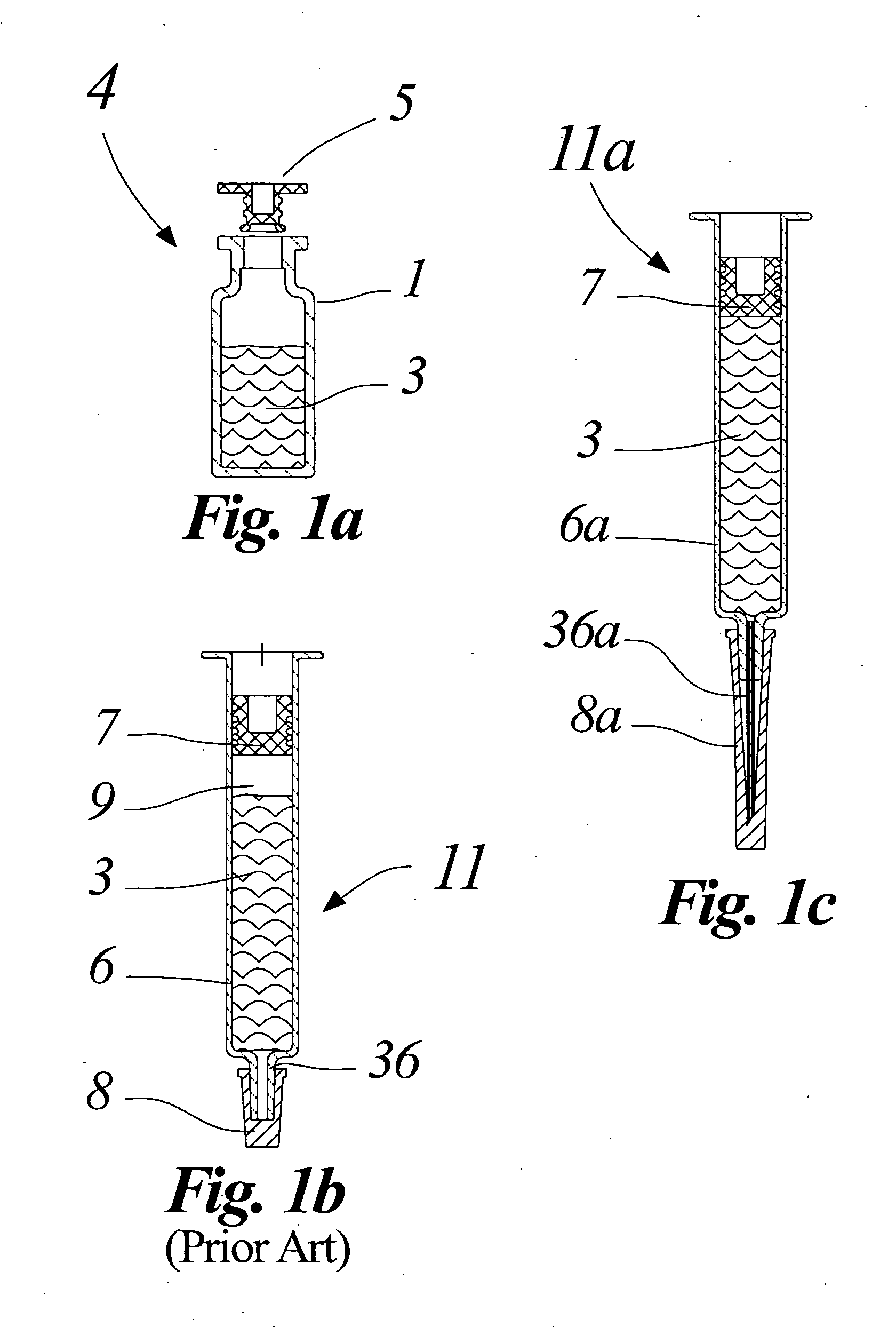

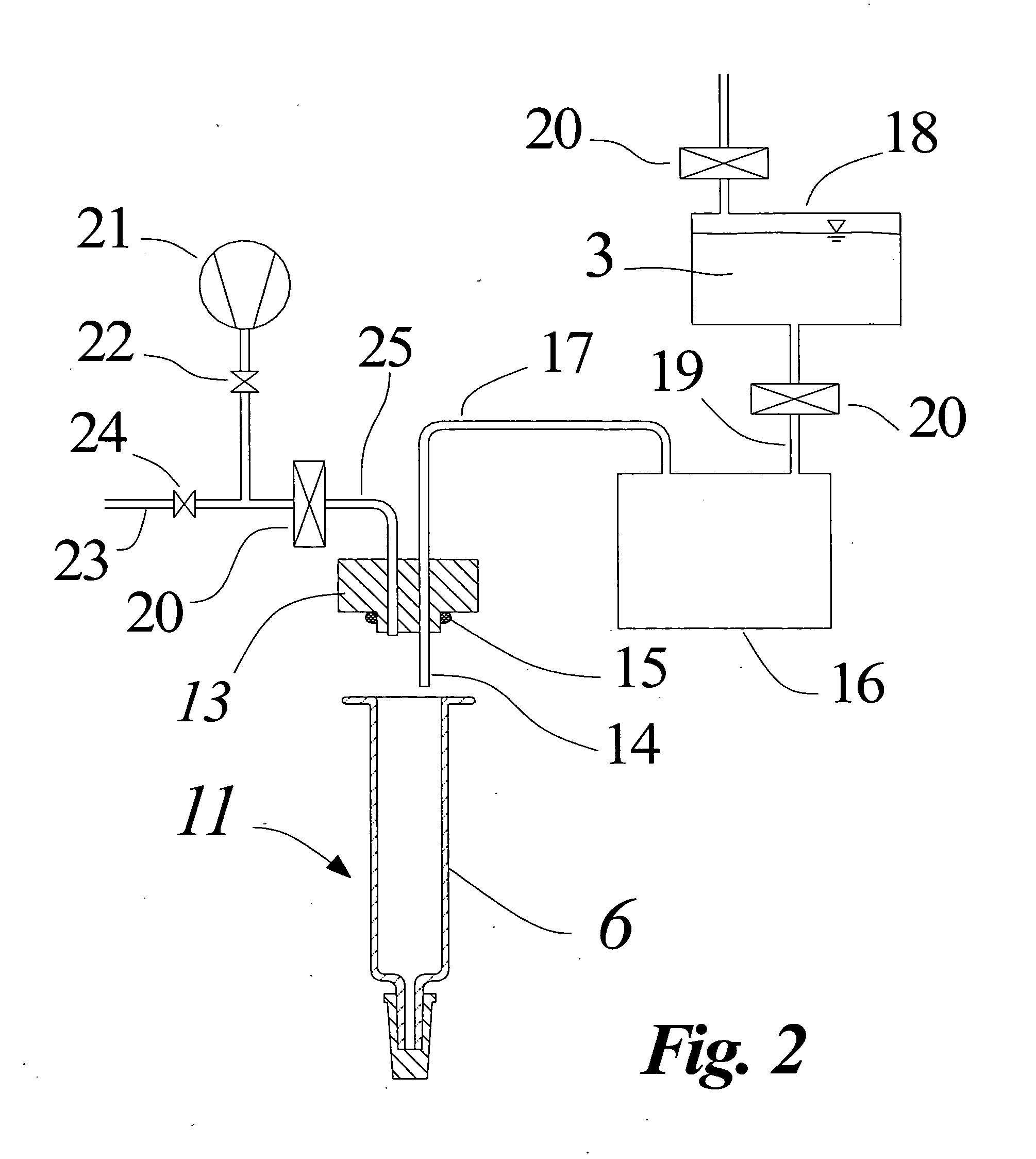

[0037] Systems and methods for filling and closing containers substantially without formation of gas pockets or foaming are disclosed. FIGS. 1A to 1C depict examples of containers that can be filled and / or closed according to the present invention. As shown in FIG. 1A, a rigid body or vial 4 can be partially filled with liquid 3. The rigid body 4 includes a hollow element 1 for holding the liquid 3, and a stopper 5 which serves as a closing element. As depicted in FIG. 1A, the rigid body 4 has been partially filled with liquid, but has not yet been closed.

[0038] Referring to FIG. 1B (PRIOR ART), a syringe 11 is another type of container which can be filled with liquid and closed according to the present invention. The syringe 11 includes a syringe body 6 for holding liquid 3 inside the syringe, which is closed at a top end by a piston 7, where a cone 36 formed at a bottom end of the syringe body 6 preferably is closed by a tip cap 8. The piston 7 can be any suitable component for c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com