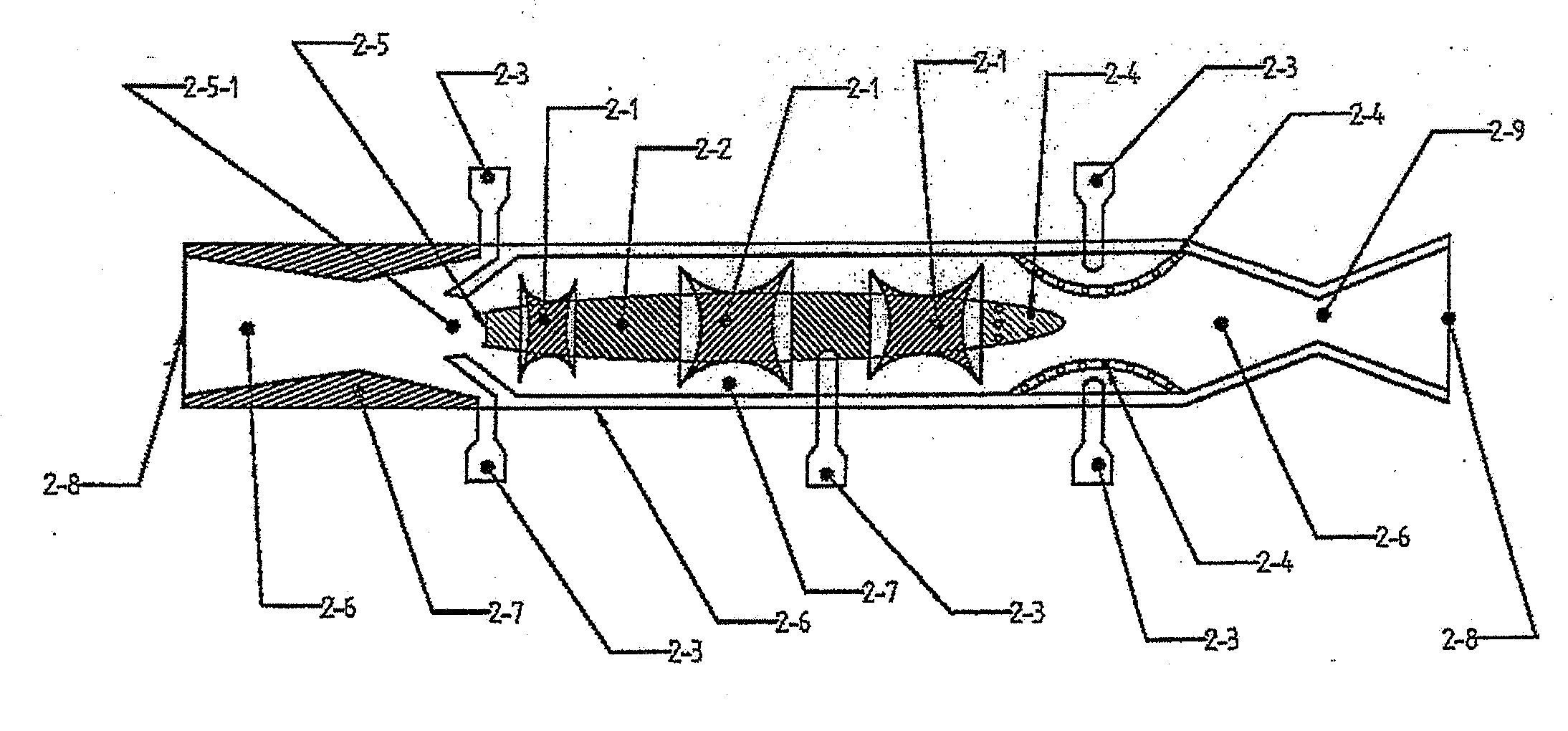

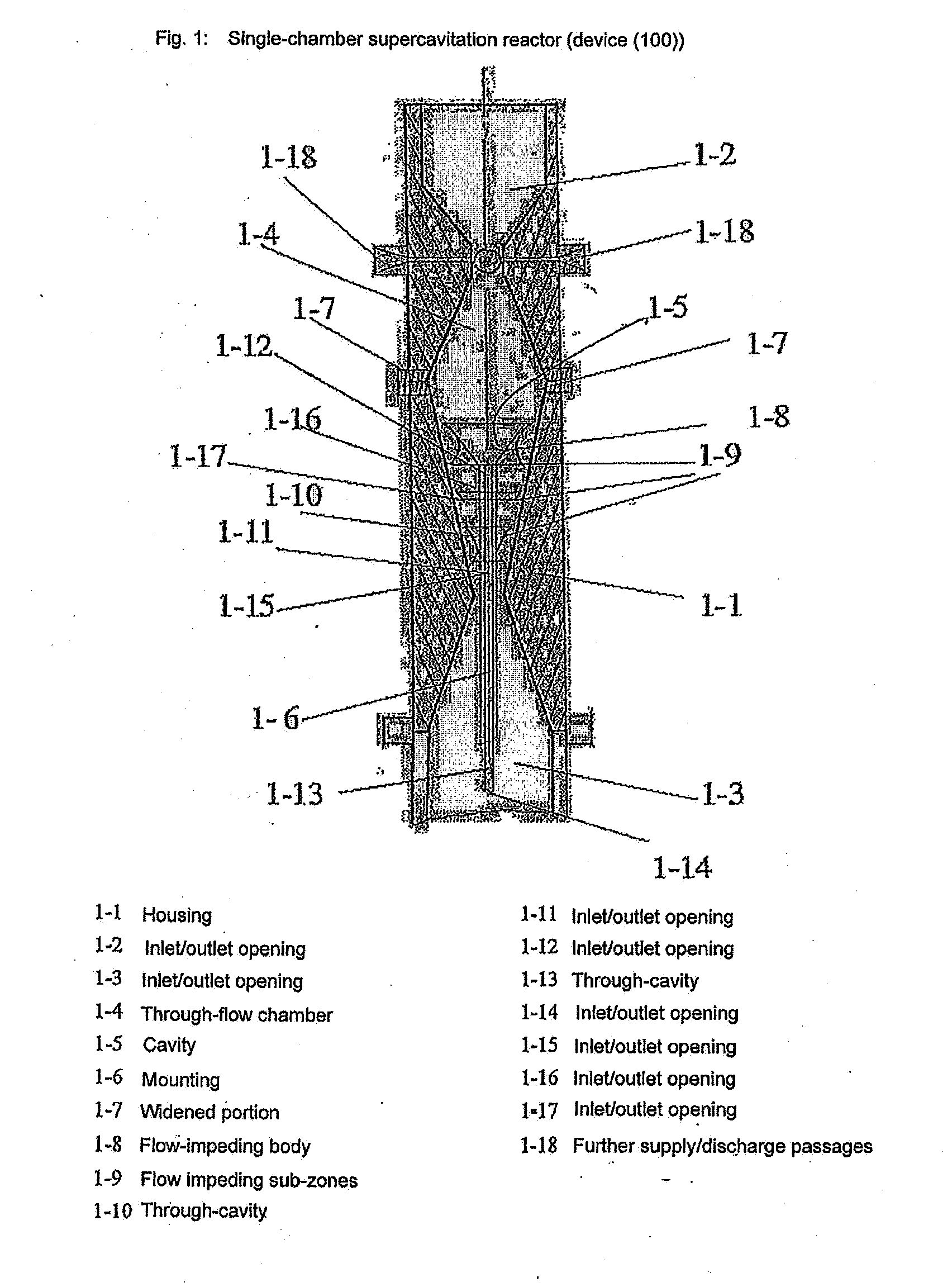

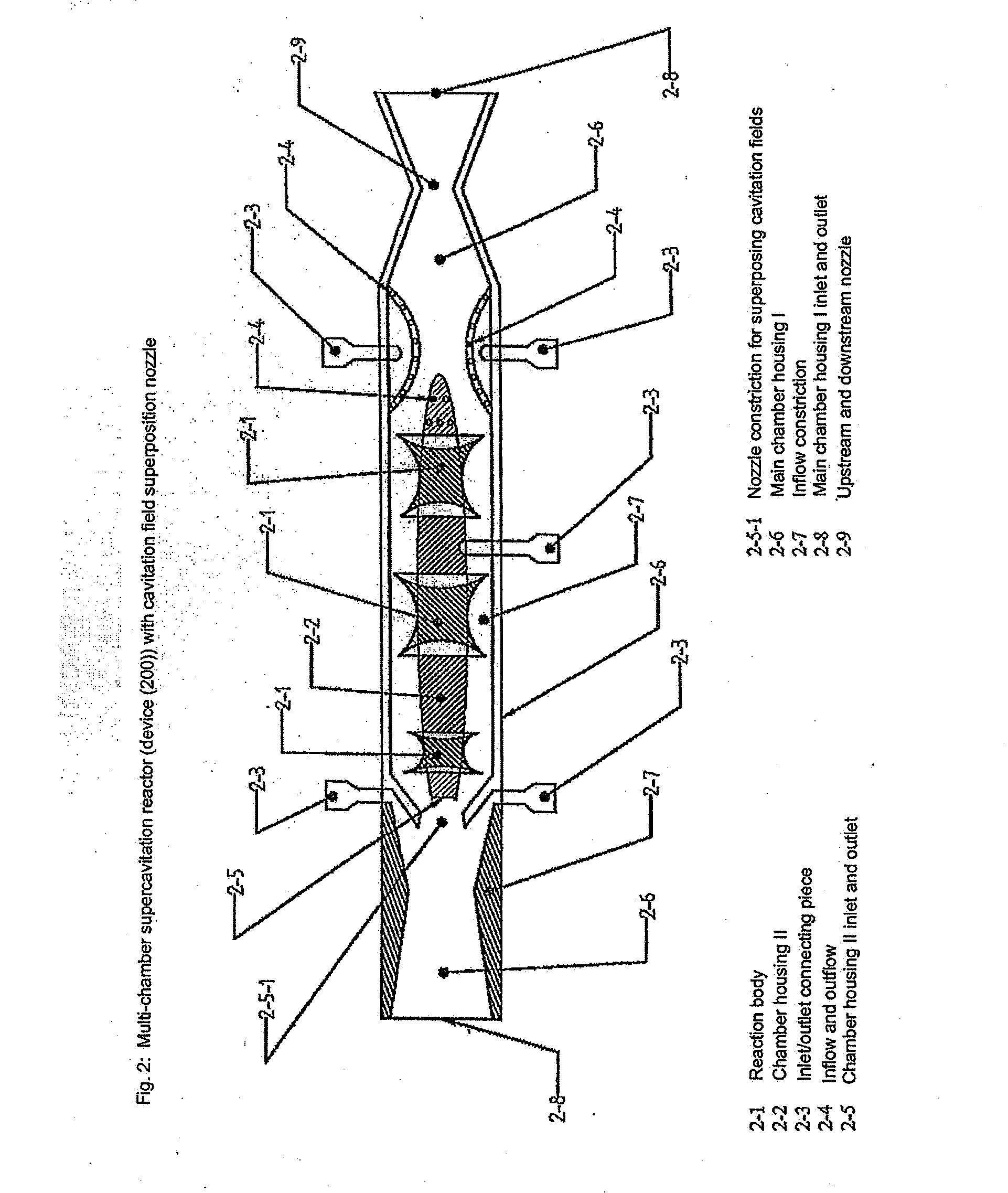

Multi-chamber supercavitation reactor

a reactor and chamber technology, applied in the field of multi-chamber super-cavitation reactors, can solve the problems of difficult to achieve, limited regulability and/or maximum admission pressure, and high energy consumption of cavitation fields generated by ultrasound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

1. Improved Operation

[0097] As compared to other systems of the prior art (DE1009326), higher degrees of mixing at lower pressure have been achieved in experiments with the device (100). The number of cycles of any required repetitions of the process is thereby also reduced. All these simplifications represent an optimization of the cost potential in application. Especially in comparison to energy-intensive cavitation generating methods such as ultrasound and laser technology, the invention represents a low-cost, less energy-intensive method which is simpler to control and install.

2. New and Improved Applications

[0098] In the degassing of water a smaller quantity of dissolved gases (e.g. oxygen) was demonstrated even after a single reaction cycle than with >5 reaction cycles using systems of the prior art.

[0099] In the mixing of hydrophobic and hydrophilic substances, faster, more efficient and more long-lasting mixing was achieved. For example, an emulsion of water in fuels h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass flow | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| total mass flow | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com